Magnetron Sputtering Source Cluster Flanges

The AJA magnetron sputtering sources can be mounted to a wide variety of cluster flange configurations. By incorporating the manual tilt, in-situ tilt or linked in-situ tilt options, the focal point of the sources can be adjusted to optimize uniformity for different working distances and materials. Conventional sputtering wisdom suggests that to achieve good uniformity for different working distances and materials, the source must be larger than the substrate. With a variable tilt angle however, excellent uniformity is achievable with sources which are smaller than the substrate. For example, uniformities of better than +/- 1% have been achieved on 4.0" Ø substrates with angled A320-XP and ST20 sources (2.0" Ø target) and simple substrate rotation. For users building their own system, incorporating an AJA cluster flange with in-situ tilt and an AJA rotating, heated, RF biasable substrate holder, can guarantee proven performance and eliminate design errors which limit system performance and flexibility.

As the world leader in flexible magnetron sputtering source design, AJA also manufactures many varieties of UHV cluster flanges which integrate anywhere from (2) to (12) A300-XP series magnetron sputtering sources onto a single vacuum flange. With the increasing demand for co-deposited thin films of varying stoichiometries and both magnetic and non-magnetic multilayers, AJA cluster flanges offer the most extensive range of possibilities currently available on the market.

- UHV in-situ tilt configurations to vary incident angle

- Compact, fixed angle configurations with flip-top shutters

- ISO, CF, wire seal, base plate, top plate and dished head versions available

- Individual source gas rings for reactive sputtering applications

- Integrated source shutter packages with automated controllers

- Individual shielding chimneys to eliminate cross-contamination and reduce operating pressure to less than 0.5mTorr

Sputter down cluster flange with in-situ tilt.

Sputter down cluster flange with fixed angle sources and flip shutters.

Flange accepts up to (5) 2” sources.

In-situ tilt in a con-focal orientation for uniform deposition onto 100 mm Ø.

sources having in-situ tilt and long conical chimneys

for operation below 0.5 mTorr.

fixed sources fitted with flip shutters.

Axial Turret Sputtering Sources

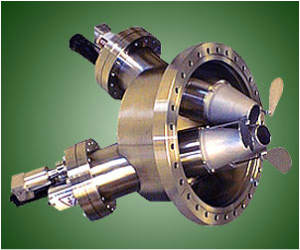

The Axial Turret design locates multiple source heads, oriented axially, on the end of a rotatable support tube running through a hollow shaft, UHV, ferroflluid rotary vacuum feedthrough. The source heads are cooled and powered through the support tube and the assembly is indexed to aim the desired source at the substrate. A single port can be used to introduce multiple magnetrons into a deposition chamber. An interesting version shown has tilt gimbals on each source allowing further articulation of the source head. Turrets are available with up to 12 heads.

Radial Turret Sputtering Sources

The Radial Turret design locates multiple source heads, oriented radially, on the end of a rotatable support tube running through a hollow shaft, UHV, ferroflluid rotary vacuum feedthrough. The source heads are cooled and powered through the support tube and the assembly is indexed to aim the desired source at the substrate. A single port can be used to introduce multiple magnetrons into a deposition chamber. Turrets are available with up to 12 heads and integral RF/DC matchbox/switchbox modules.

Unique Modular Magnet Array

AJA's magnetron sputtering sources feature a unique "modular magnet array" which is completely isolated from the cooling water to eliminate magnet deterioration and subsequent degradation of source performance. This design permits access to the internal magnet arrangement thus allowing the same source to be:

- Operated as a balanced magnetron

- Configured for maximum target utilization

- Configured for high or low rate sputtering

- Operated in a variety of unbalanced magnetron configurations

- Changed for uniform or intentionally non-uniform depositions

- Configured for high or low electron energies as they arrive at the substrate surface

- Operated with thick magnetic material targets

- Optimized for easy magnetic target removal and replacement

Typical Features

- Modular magnet array isolated from cooling water

- Magnetic material sputtering of thicker targets

- Easy removal of larger magnetic targets

- Integral gas injection and chimney system

- Efficient target cooling with no vacuum/water seals

- Clamped target mounting for optimal heat transfer

- RF & DC compatibility

- Rugged HV construction

- Operating pressure: (0.3 mTorr - 1.0 Torr)

- In-situ tilt or manual tilt for optimum uniformity

- Custom versions available

- Source/power supply/target packages available

Typical Applications

- CD/DVD disk coatings (e.g. reflective, phase change)

- Semiconductor

- Conductive metal/resistive metal/Insulating Films

- Transparent electrical conductors (e.g. ITO)

- Optical communications applications (e.g. pump lasers)

- Wear resistant films

- Lens coatings (reflective/anti-reflective/ hard/color)

- Precious metals (for maximum target utilization)

- Thin film sensors

- Coatings for surgical/medical implements & implants

- Magnetic storage media and heads (HD, GMR , TMR)

- Photovoltaic thin films (solar cells)