- Enable rapid cooling of sample area to near 1°C

- All chiller models can be used for frame cooling

- C300W, C500W, and C610W require the FVC9 coolant flow control system for sample cooling using the mK2000 out2 port

- C300W, C500W, and C610W require the FVC1 coolant flow control system for frame cooling of thermoelectric stages using the mK2000 out3 port

FEATURES

• Recirculating chillers with ice water compartments provide rapid cooling of sample area to near 1°C (depending on model)

• All chiller models can be used for frame cooling

• C300W, C500W, and C610W require the FVC9 coolant flow control system for sample cooling using the mK2000 out2 port

• C300W, C500W, and C610W require the FVC1 coolant flow control system for frame cooling of thermoelectric stages using the mK2000 out3 port

SPECIFICATIONS

|

Chiller |

Dimensions |

Weight |

Temperature Range |

|

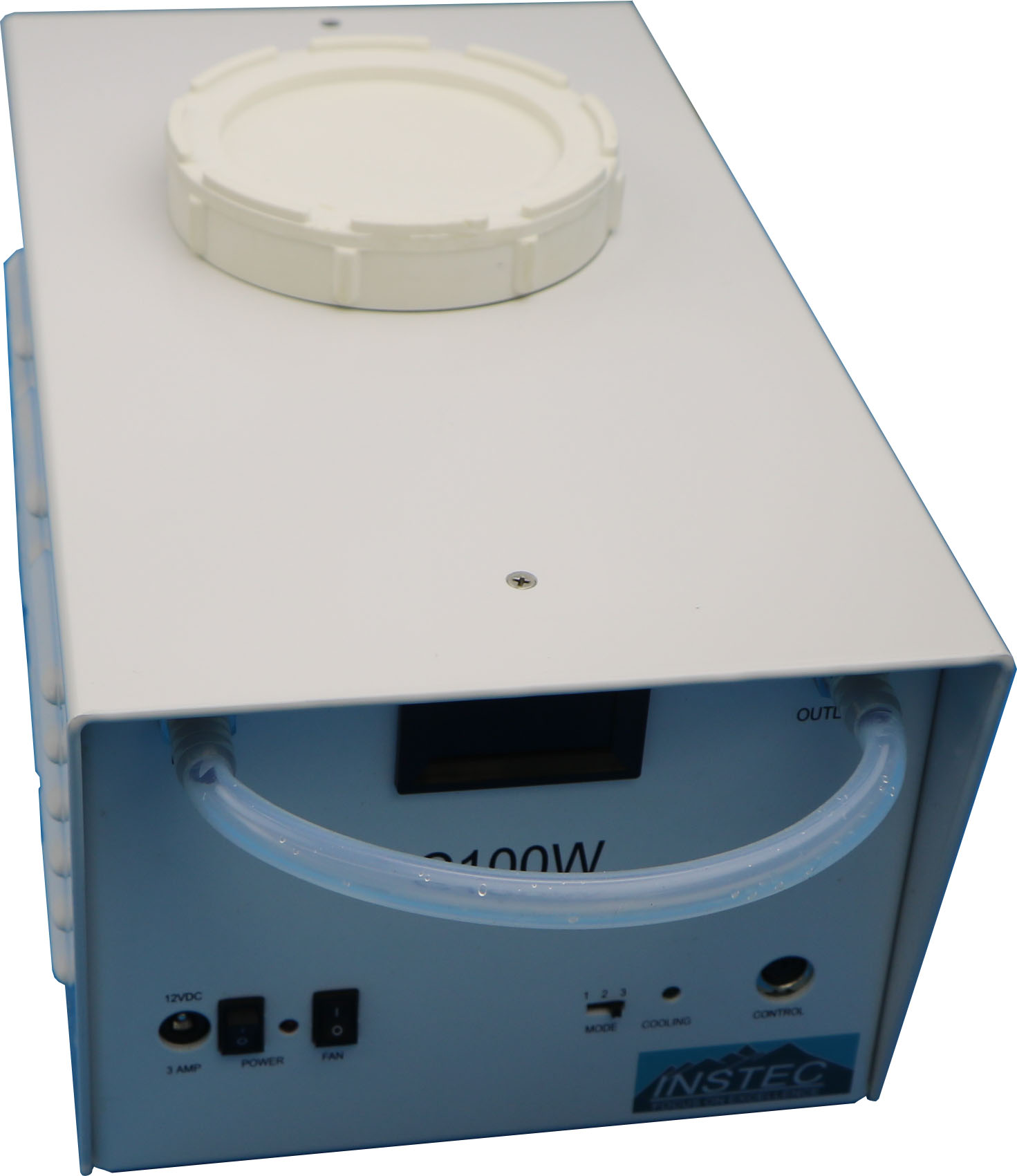

C100W |

30cm x 18cm x 17cm |

3.7 kg |

20°C - 50°C |

|

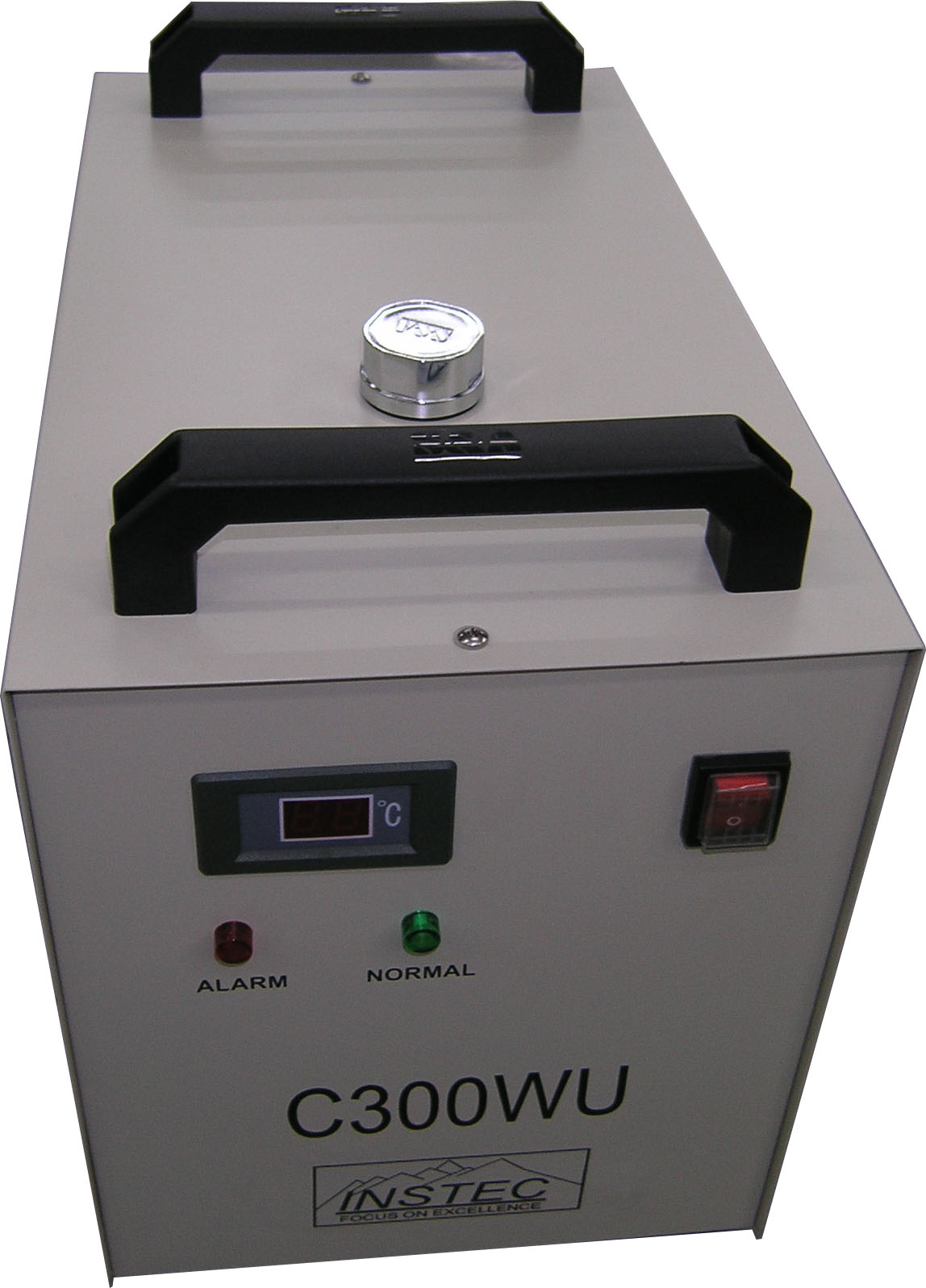

C300W/C300W-R |

47cm x 37cm x 27cm |

14.5 kg |

20°C - 50°C |

|

C500W/C500W-R |

56cm x 46cm x 28cm |

37 kg |

1°C - 50°C |

|

C610W |

89cm x 71cm x 48cm |

65 kg |

1°C - 50°C |