Monte Carlo simulation of thin film deposition for industrial continuously running-through flat panel coating systems

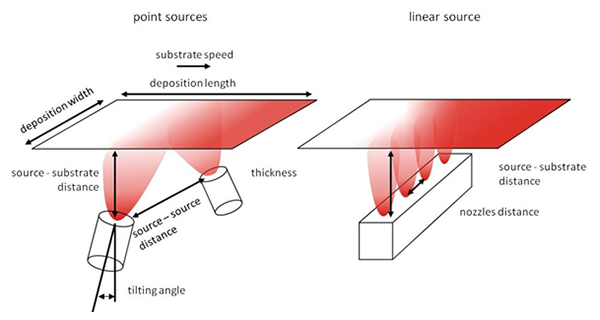

Schematic illustration of the deposition process with pairs of point sources, or with a linear evaporation source, which deposit material onto linear moving flat panels.

-

Why MC-Simulation?

It provides important information while saving time and money

-

MC-Simulation allows the optimization of

- source design

- source arrangement

- deposition chamber layout

-

It provides information about

- layer uniformity

- material efficiency

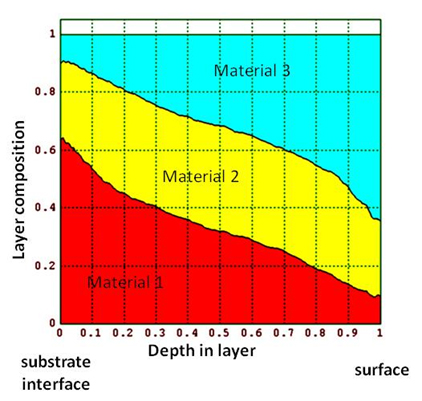

- layer composition -

For single material deposition and co-evaporation

Monte Carlo simulation allows to calculate the flux distribution of various types of evaporation sources. It provides information on the resulting flow rate distribution, material composition on the substrate, and material efficiency, thus allowing to optimize source design, source arrangement and depositon system layout.

An example for large area industrial flat panel deposition is illustrated schematically in the figure above. A pair of point sources (left part) or alternatively a linear evaporator (right part) is applied for the material evaporation. The source material or, in a co-deposition process, various source materials are deposited onto continuously running-through flat panels.

|

|

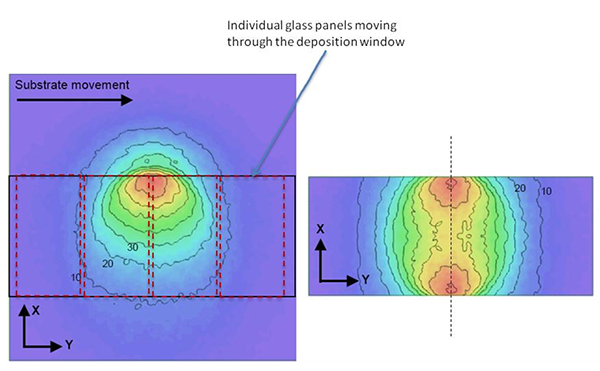

| Figure 1: Simulation of the flux distribution on a stationary substrate, assuming a single effusion cell using an insert for beam shaping. The black rectangle represents the deposition window of 125cmx300cm. Figure 2: Combined flux distribution on the substrate by two symmetrically aligned effusion cells. |

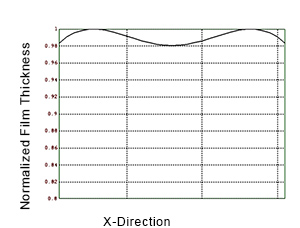

The figure above shows the flux distribution profiles for two point sources. The inset shows the normalized film thickness profile across the flat panel.

The MC simulation provides important information and saves time and money. It allows the optimization of source design, source arrangement and the deposition chamber layout. It provides information about the layer uniformity, the material efficiency and the layer composition in a co-deposition process. Simple planar substrates as well as patterned or textured substrates can be calculated.

Film thickness profile integrated along the deposition window generated by two point sources |

Example of the material composition for 3 co-evaporated materials for a defined sources arrangement |

We offer the deposition simulation for your MBE or PVD system as a service. For a specific simulation geometrical boundary conditions of the deposition setup are required.