Effusion Cells

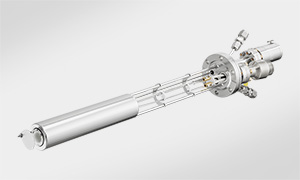

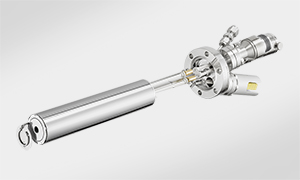

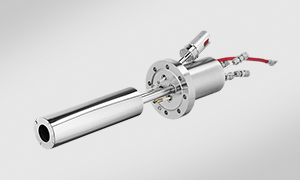

WEZ, Standard Effusion Cell

WEZ Standard Effusion Cells are designed for evaporation or sublimation of a variety of elements and compounds in the temperature range from 700°C up to 1400°C.

- Applicable in most UHV systems up to 1400°C

- Compatible with all standard MBE crucibles

- Crucible capacities from 2 to 200 cm³

- Most effective heating system with excellent reliability and long lifetime

- Hot lip, cold lip and dual filament designs

- Optional on-flange integrated cooling shroud and shutter

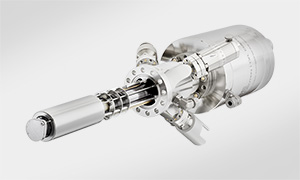

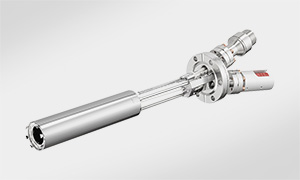

PEZ, Production Effusion Cell

PEZ Production Effusion Cells are designed to meet the particular requirements of production MBE systems, allowing the evaporation of a variety of elements.

- Compatible with standard MBE systems, e.g. from Varian, EPI, Veeco, VG, or Riber

- Crucible capacities 40-1700 cm³

- Precise run-to-run flux reproducibility

- Customized beam shaping crucible inserts available

- Excellent reliability and long lifetime

- Hot lip, cold lip and dual filament designs

- Optional integrated cooling shroud

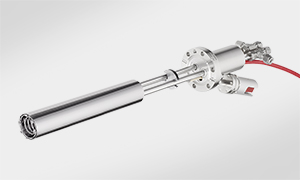

NTEZ, Low Temperature Effusion Cell

NTEZ Low Temperatur Effusion Cells are designed for evaporation of high vapor pressure materials that require a precise temperature control and reproducibility.

- Applicable in most UHV systems

- Evaporation of metals, compounds and organic materials between 80°C and 1000°C

- Crucible capacities from 2 to 200 cm³

- Robust, reliable tantalum wire heating system

- Excellent temperature stability and controllability

- Optional on-flange integrated cooling shroud and shutter

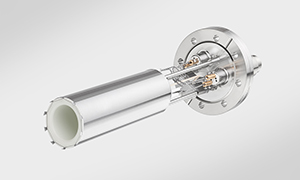

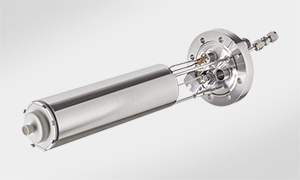

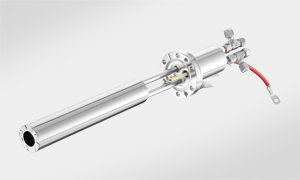

TCC, Thermal Cracker Cell

The Thermal Cracker Cell TCC is an effusion cell with additional cracker stage inside and integrated water cooling shroud on a space-saving DN40CF flange.

- Full PBN solution for corrosive materials like Te, Sb, Se, As, Mg

- DN40CF (O.D. 2.75" ) mounting flange compatible with all MBE systems

- Thermal cracking up to 1300°C

- 35 cm3 or 130 cm3 PBN crucible

- Excellent thermal isolation between low temperature reservoir and hot cracking zone

- Integrated water cooling for cracker stage

- Integrated rotary shutter

OME, Organic Material Effusion Cell

The patented Organic Material Effusion Cell OME was specially designed for the evaporation of volatile organic substances at operating temperatures up to 300°C.

- Patented Thermal Conduction Cooling (TCC)

- Ideal for evaporation of sensitive organic materials in UHV and OLED applications

- Temperature range 15-300°C

- Fast and precise temperature control < ±0.02K with excellent temperature stability

- Crucibles capacities 2 cm³, 10 cm³ and 35 cm³

- Full UHV and MBE compatibility

OREZ, Oxygen Resistant Effusion Cell

OREZ Oxygen Resistant Effusion Cells with nickel or noble metal heaters meet the requirements of oxide MBE applications with high oxygen background pressure.

- Oxygen resistance option available for most wire heater effusion cells

- Applicable in oxide MBE systems with chamber pressures up to several mbar

- Nickel alloy wire heaters up to 1000°C

- Noble metal alloy wire heaters up to 1200°C

- Ultimate oxygen resistance by use of platinum shielding

- Optional on-flange integrated cooling shroud and shutter

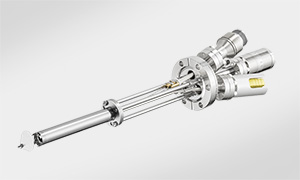

HTEZ, High Temperature Effusion Cell

- Compatible with most MBE systems

- Various crucible sizes and materials;

- crucible capacities 1.5, 10, and 35 cm³

- Self-supporting tungsten wire heater

- Clean operation in UHV up to 1900°C

- High reliability and long lifetime

- Cell option with integrated cooling shroud and shutter

HTEZ-W, High Temperature Effusion Cell

Equipped with a free-standing filament of thick tungsten wire, the model HTEZ-W is capable of reaching 2000°C. HTEZ-W cells work completely without any additional ceramic insulation.

- Compatible with most MBE systems

- Various crucible materials; crucible capacity 10 cm³

- No ceramic insulation parts in hot area

- Free-standing thick tungsten wire filament

- Clean operation in UHV up to 2000°C

- High reliability and long lifetime

- Water cooled current contacts

HTS, High Temperature Source

The High Temperature Source HTS allows evaporation of high vapor pressure materials, thereby combining very uniform material deposition with high flux rates.

- Clean operation in UHV up to 2000°C

- Excellent beam uniformity for doping and layer growth applications

- Flat pyrolytic graphite or tungsten wire filaments

- Wide opening crucibles with capacities from 5 to 200 cm³

- Various crucible materials

- No ceramic parts in the hot zone

DECO, GaP Decomposition Source

The Decomposition Source DECO is an ultra-pure source for P2 based on the decomposition of GaP. It is an affordable and easily operated alternative to valved phosphorus sources.

- High-purity phosphorus (P2) source

- Simple and safe operation with non-inflammable GaP source material

- Compatible with most UHV and MBE systems

- Various crucibles from 10 to 420 cm³

- Precise and fast flux control with high reliability

- Optional on-flange integrated cooling shroud and shutter

SUSI, Silicon Sublimation Source

The Silicon Sublimation Source SUSI was developed for growing thin Si layers, short period Si/Ge superlattices and Si/SiGe heterostructures. It allows for growth of thin epitaxial Si layers with a crystal quality not otherwise possible by evaporation.

- Thermal sublimation of silicon from high purity intrinsic or highly doped Si filament

- Excellent growth of thin silicon layers

- Compatible with most MBE systems

- Water-cooled electrical contacts

- Inner filament shielding with pure silicon parts

- No ceramic parts in the hot zone

SUKO, Carbon Sublimation Source

The SUKO provides clean and stable flux at a low deposition rate of up to 2 Å/min. It has been successfully applied in a variety of research fields, e.g. graphene formation.

- Thermal sublimation of carbon from high purity graphite filament

- Excellent growth of thin carbon films or Si-C alloys

- Compatible with most MBE systems

- Water-cooled electrical contacts

- Inner filament shielding with pure pyrolytic graphite parts

- No ceramic or metal parts in the hot zone

SUKO-A, Atomic Carbon Sublimation Source

- Thermal sublimation of atomic carbon

- Refractory metal tube filament filled with ultrapure carbon

- Only pyrolytic graphite and tantalum parts in hot area

- Water-cooled power feedthrough

- Cooling shroud and shutter optionally available

- Compatible with UHV analysis systems and MBE growth chambers