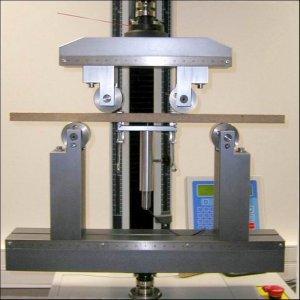

Flexure tests are generally used to determine the flexural modulus or flexural strength of a material. A flexure test is more affordable than a tensile test and test results are slightly different. The material is laid horizontally over two points of contact (lower support span) and then a force is applied to the top of the material through either one or two points of contact (upper loading span) until the sample fails. The maximum recorded force is the flexural strength of that particular sample.

Learn more about Bend Test Machines...

Why perform a flexure test?

Unlike a compression test or tensile test, a flexure test does not measure fundamental material properties. When a specimen is placed under flexural loading all three fundamental stresses are present: tensile, compressive and shear and so the flexural properties of a specimen are the result of the combined effect of all three stresses as well as (though to a lesser extent) the geometry of the specimen and the rate the load is applied.

The most common purpose of a flexure test is to measure flexural strength and flexural modulus. Flexural strength is defined as the maximum stress at the outermost fiber on either the compression or tension side of the specimen. Flexural modulus is calculated from the slope of the stress vs. strain deflection curve. These two values can be used to evaluate the sample materials ability to withstand flexure or bending forces.

Learn more about Flexural Bend Test Fixtures...

Flexure Test Types:

The two most common types of flexure test are three point and four point flexure bending tests. A three point bend test consists of the sample placed horizontally upon two points and the force applied to the top of the sample through a single point so that the sample is bent in the shape of a “V”. A four point bend test is roughly the same except that instead of the force applied through a single point on top it is applied through two points so that the sample experiences contact at four different points and is bent more in the shape of a “U”. The three point flexure test is ideal for the testing of a specific location of the sample, whereas, the four point flexure test is more suited towards the testing of a large section of the sample, which highlights the defects of the sample better than a 3-point bending test.

A bend test is similar to a flexure test in the type of hardware and test procedure involved. Bend tests are used with ductile materials whereas flexural tests are used with brittle materials.

Learn more about Bend Test Machines...

Types of Materials:

Generally a flexure test is run until the sample experiences failure and is therefore ideal for the testing of brittle materials. The most common materials tested in flexure are plastic materials, composites, concrete, and ceramics. Because these materials have a very low ductility they will break before any permanent deformation of the sample occurs allowing for the accurate measurement of the flexural modulus and strength.

Learn more about Flexural Bend Test Fixtures...

Selected Test Standards

- ASTM C1211 Flexural Testing for Ceramics

- ASTM C1583 Tensile Testing for Concrete Surfaces

- ASTM C1674 Ceramic Flexural Strength Test Equipment

- ASTM D6272 Four Point Flexural Bend Test Machine for Plastics and Insulating Materials

- ASTM D6416 Flexural Sandwich Composite Plate Composite Test Machine

- ASTM D7264 Flexural Test Equipment for Polymer Matrix Composite Materials

- ASTM D790 Testing for Flexural Properties of Plastics and Insulating Materials

- ASTM F2606 Bending Balloon Vascular Stents 3 Point Test Machine

- ASTM F382 Flexural Fatigue Bone Plate Fixation Devices Test Equipment

- ISO 14125 Plastic Composites Flexure Bend Test Machine

- JEDEC JESD 22B113 Board Level Cyclic Bend Test - Handheld Electronic Products

- IPC JEDEC 9702 Monotonic Bend Testing Interconnects - Board Level

Selected Applications

- 3 and 4 Point Flexural Bend Test Equipment for Composites

- Equibiaxial Ring on Ring Ceramic composite flexural strength per ASTM ISO

- Composites Flexural Bend Testing Equipment

- Flexural Test of Plastics & Composites using Three and Four Point Bend Fixtures

- Glass Strength Bend Test Equipment

- Flexure Test of Insulation Materials - Four Point Bend

- How to define test equipment requirements for flexural properties of plastics

- Thermal Insulation Materials Flexural Bend Properties (ASTM C203 and ISO 1209)

- Flexural Bend Test Fixtures and Equipment for Ceramics

- Three Point Flexural Bend Test Fixture for Plastics

- Fiber Reinforced Concrete Flexural Bend Test Equipment

- Flexural Tests of Fiber Reinforced Concrete