Combined axial and torsional loading, or biaxial tests are common to metals testing, biomechanics, tissue engineering, orthopedics and composites testing applications.

Purpose of Axial Torsion Biaxial Testing:

Axial torsion tests replicate anticipated or recorded service loading conditions that involve combinations of axial or linear loading with torsional or rotary loading. They are also used by materials developers to characterize the behavior of materials over a wide range of loading ratios.

Common Axial Torsion Tests:

In metals testing, relatively high force/torque test machines are involved to generate constitutive modeling of tubular test samples. By changing the ratio of loading to torsional loading and by using special extensometers, the material properties researcher can develop a model of how a material behaves under various loading combinations.

The medical industry has multiple applications, including the case of medical implants, where axial torsional fatigue test machines are involved in hospitals where medical surgeons want more and better understanding to support leading edge developments and solutions for specific patient problems. There are also quite a few industry standards where combined loading is needed, including the spine, the knee, the hip, the shoulder and other joints.

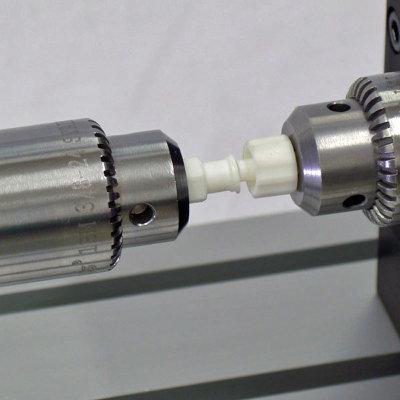

In the case of luer connectors, biaxial combined axial torsional tests involve combined loading (axial plus torsion) to prove they are a reliable connection.

Selected Test Standards

- ISO 80369-1 Axial Torsional Luer Connector Test Equipment

- ISO 594-1 & 2 Separation Force and Unscrewing Torque Testing for Luer Tapers

- ASTM F543 Medical Bone Screw Torsion Test Equipment

- ASTM F2077 Fatigue Compression Torsion Shear Intervertebral Fusion Device Test Equipment

- ASTM F1717 Spinal Implant Static and Fatigue Test Equipment

- ASTM E2207 Axial-Torsional Fatigue Thin-Walled Tubular Materials Test Equipment