Fracture toughness tests measure a material’s ability to resist the growth or propagation of a pre-existing flaw. The flaw or defect may be in the form of a fatigue crack, void, or any other inconsistency in the test material. Fracture toughness tests are performed by machining a test sample with a pre-existing crack and then cyclically applying a load to each side of the crack so that it experiences forces that cause it to grow. The cyclic load is applied until the sample’s crack grows. The number of cycles to fracture is recorded and used to determine the material’s fracture growth characteristics.

Purpose of fracture toughness testing:

Fracture toughness is the stress that causes a pre-existing crack or flaw to grow or propagate. It is an important material property in the manufacturing industry, since the presence of flaws is not completely avoidable. The stress intensity factor, which is a function of the flaw size, geometry, and loading, is used to determine a material’s fracture toughness. A material’s stress intensity factor and fracture toughness are related to one another in the same manner that stress and tensile stress are related to each other.

Types of fracture toughness tests:

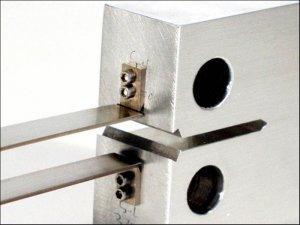

For the majority of fracture toughness tests there are three different modes of fracture for crack propagation. Mode 1 requires that the applied load be in the normal direction of the crack plane. In mode 2 the load is applied along the length of the crack plane. Finally, for mode 3 the load is applied across the width of the crack plane. Generally there are two different configurations for the test sample: single edge notch bend (three point bending) and compact tension. A three point bending specimen has the initial crack located at the midsection on the opposite side from the point where the midsection load is applied with opposing points of force located at each end on the same side as the crack. A compact tension specimen is oriented so the load is applied on each side of the crack in a way that extends the width of the crack.

Types of materials tested with fracture toughness tests:

Nearly all manufactured materials will contain a defects, flaws or cracks to some magnitude and may experience fracture due to these inconsistencies and when or if this does occur the fracture toughness of that material will be exhibited. The materials that are most commonly tested for fracture toughness are similar to those tested in fatigue tests but have slightly different orientations. These materials include metals, plastics, ceramics and composites among others as well as many other rigid substrates that may contain defects.

Selected Test Standards

- ASTM D5045 Fracture Toughness and Strain Energy Release Rate of Plastic Materials

- ASTM D5528 Interlaminar Fracture Toughness of Fiber-Reinforced Polymer Matrix Composites

- ASTM D6068 J Integral Crack Growth Resistance Curves of Plastics

- ASTM D6671 Interlaminar Fracture Toughness of Fiber Reinforced Polymer Matrix Composites

- ASTM E1290 Fracture Toughness Test Equipment

- ASTM E1457 Creep Crack Growth Metal Test Equipment

- ASTM E1820 Fracture Toughness Test Equipment for Metals

- ASTM E1922 Fracture Toughness Polymer Matrix Composites Notched Test Equipment

- ASTM E399 Linear-Elastic Plane-Strain Fracture Toughness (K1c) Testing of Metallic Materials

- ASTM E647 Fatigue Crack Growth Test Equipment

- ASTM F2136 Crack Growth HDPE Resins NCLS Test Equipment

- ISO 12108 Fatigue Crack Growth Method for Metallic Materials

- ISO 12135 Quasistatic Fracture Toughness for Metallic Materials

- ISO 13586 Fracture Toughness of Plastics by the Linear Elastic Fracture Mechanics Approach

- ISO 15653 Quasistatic Fracture Toughness of Welds

- ISO 15850 Tension-Tension Fatigue Crack Propagation Plastics Test Equipment

- ISO 16241 Tensile Crack Growth Polyethylene Pipe Test Equipment BS| TestResources

- ISO 18756 Flexure Test - Fracture Toughness of Monolithic Ceramics Surface Crack

- ISO 22889 Resistance to Stable Crack Extension Using Specimens of Low Constraint for Metallic Materials

- ISO 23146 Fine Advanced Fracture Toughness of Monolithic Ceramics - Single-Edge V-Notch Beam (SEVNB)

- ISO 25217 Adhesive Fracture Energy of Structural Adhesive Joints

- ISO 9017 Welds in Metallic Materials Fracture Test

Selected Applications

- Fatigue Crack Growth at Elevated Temperatures

- Fatigue Crack Growth Test Machines and Accessories

- Fracture Toughness Test Equipment for Advanced Ceramics

- Fracture Toughness Test Equipment for Engineered Composites

- Fracture Toughness Test Equipment for Plastics

- Fracture Toughness Test for Metallic Materials K1C | TestResources

- J-Integral Fracture Toughness Test Equipment J1C

- Metals Crack Growth Planar Biaxial Mode

- Metals Fracture Toughness Testing | Machines & Equipment

- Metals Fatigue Crack Propagation Tests with Variable Amplitude Loading