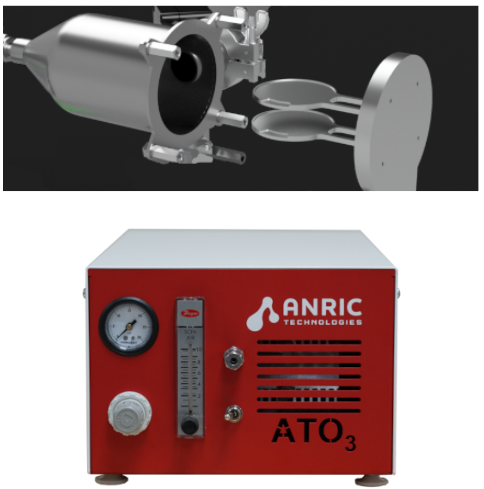

AT 200M – The Most Cost Effective ALD System on the Market

Anric Technologies introduces the smallest footprint ALD (Atomic Layer Deposition) tool available on the market. The AT200M is small enough to fit in a glovebox and therefore the perfect solution for moisture or air-sensitive depositions.

- Small footprint (~ 15 in3 or 38.1 cm3: W: 14″ (35.5 cm) x D: 15″ x (38.1 cm) x H: 14.5″ (36.5 cm))

- Fits Inside a Glovebox

- Accommodates samples from 2″ x 2″ x 3″ or four 2″ round/square wafers (customizable chucks/8 x 2″ cassette)

- One precursor and one counter-reactant (also avail. our 4 port option: 3 precursors and 1 counter-reactant OR 2 precursors and 2 counter-reactants)

- NEW – AT 200M Plus with 13.56MHz, 80W Hollow Cathode Plasma Source (1 standard MFC and up to 2 available).

- Semiconductor grade components with metal-sealed lines

- Vented precursor enclosure

- High temperature compatible, fast pulsing ALD valves with an ultra fast MFC for integrated inert gas purge

- Precursors (up to 175 °C) , manifold, chamber heated to insure no condensation.

- Robust PLC driven user interface (remote ethernet control via Windows is available)

- Stainless steel chamber can be heated to 300°C (Optional chuck up to 480 °C or higher)

AT 200M – The Most Cost Effective ALD System on the Market

Anric Technologies의 AT200M은 글로브박스에 들어갈 만큼 소형 ALD이므로 습기나 공기에 민감한 증착을 위한 완벽한 솔루션을 제공합니다. 본 모델은 시장에서 가장 작은 크기의 저렴한 ALD(Atomic Layer Deposition, 원자층 증착) 툴 입니다.

- 적은 설치 공간 소요 (35.5 cm W x 38.1 cm D x 36.5 cm H)

- 전구체 하나, 역반응물 하나

- 반도체 그레이드의 부품

- 금속 씰링 라인

- 통풍형 전구체 인클로저

- 불활성 가스 퍼지를 위한 초고속 MFC를 갖춘 고온, 고속 펄스 ALD 밸브

- 전구체(최대 145°C), 매니폴드, 응축 방지 가열 챔버.

- 견고한 PLC 기반 사용자 인터페이스

- 스테인레스 스틸 챔버는 290°C까지 가열될 수 있습니다.

FEATURES

- Small footprint to easily fit in glovebox or besides an evaporator for SEM/TEM.

- One precursor and one counter-reactant (expandable to 4)

- Accommodates samples from 2″ x 2″ x 3″ or four 2″ round/square wafers (customizable chucks/8 x 2″ cassette)

- Vented precursor enclosure

- High temperature compatible, fast pulsing ALD valves with an ultra fast MFC for integrated inert gas purge – standard

- Metal sealed lines

- Precursors (up to 175° C) , manifold, chamber heated to insure no condensation.

- Stainless steel chamber can be heated to 300 °C (Option to 480 °C or higher)

- 5″ Display with integrated PLC controller (no PC required)

SPECIFICATION

- Chamber temperatures from RT to 300 °C ± 1 °C

- Precursor temperatures from RT to 175 °C ± 2°C (w/ heating jacket)

- Smallest footprint on market (1.6 sq ft), bench top installation, cleanroom compatible (with all the safety interlocks of our larger systems), also fits in glovebox.

- Simple system maintenance and low utilities and precursor usage.

- Small chamber volume

- Very Fast cycling capability.

- Full HW and SW interlocks for safe operation even in multi-user environment

OPTION

- No Glovebox integration required [Fits in a glovebox (or attaches to the side of a glovebox)

- Customized chuck/platen (square, circular, double substrates, baskets, smaller pieces, thicker substrates, 8 wafer cassette).

- NEW – AT 200M Plus with 13.56MHz, 80W Hollow Cathode Plasma Source (1 standard MFC and up to 2 available).

- New: Temperature-compensated QCM

- New: 450 °C (or higher) chuck

- ATOzone – Ozone generator (required for some films: Pt, Ir, SiO2, MoO2, high quality Al2O3 below 60°C, high quality HfO2)

- Optional – Ozone Safety Monitor w real time detection of ambient ozone gas

- 4 Port Option (Ex.: 2 heated precursors, 1 unheated precursor, 1 counter reactant)

- NEW – 6 port option (Ex.: 2 heated precursors, 2 unheated precursor, 2 MFC controlled counter reactants)

- NEW – MLD option

- Powder coating drum

- External control – PC/software link (allows programing and running, remotely)

- Ventable Precursor cabinet included

INSTALLATIION

For detailed instructions see our instructions: “AT200M Installation and Start-up“

- N2 purge gas should be >99.9995% with a shutoff valve (regulated to 10 – 30 psi, metal sealed),

- Attach the nitrogen (UHP) purge gas via 1/4″ metal sealed line to 1/4″ compression fitting on back

- Attach 90-110 psi CDA (clean dry air) via 1/4″ polyethylene tubing or metal line to the other 1/4″ compression fitting

- Attach pump with appropriate 1″ vacuum (metal (SS) preferred) hose (KF25), O-Ring and clamp

- The other (exhaust side) side of vacuum pump (* perfluorinated vacuum oil like Fomblin, required) should go to standard lab exhaust or roof with > 5cfm draw (1″ tubing, also).

- Greater than 1 meter requires should use 1.5″ (NW40).

- Precursor’s attach via female VCR elbows (always use new gaskets).

- 1/4″ gasket first (with gloves on)

- For precursor attachment please refer to “AT200M Tool and Software Operation”

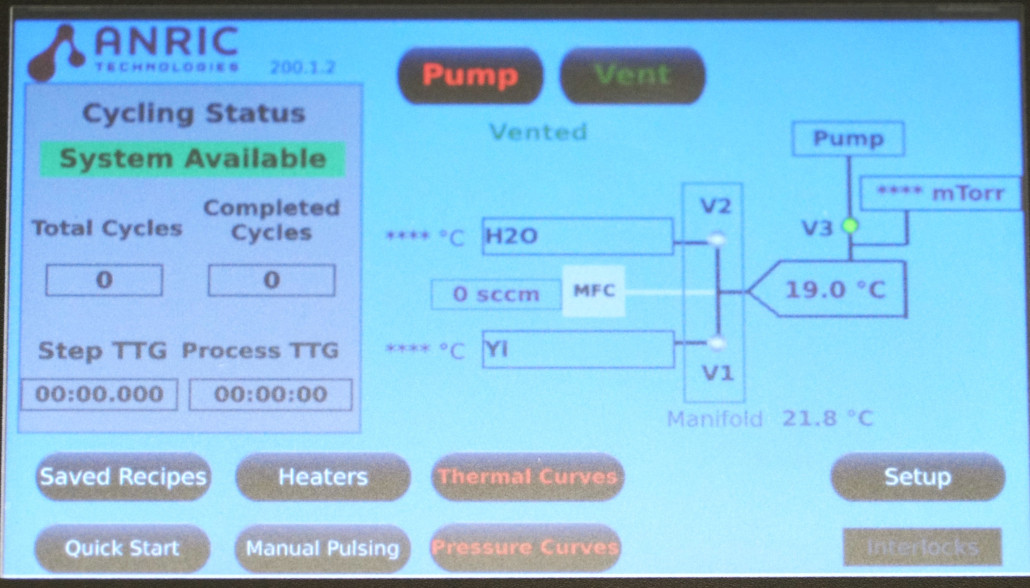

SOFTWARE

For detailed instructions see our presentation and video instructions: “AT200M Installation and Start-up“

- Human Machine Interface (HMI) PLC system with a 5” touch screen

panel - Advanced controls suitable for the deposition of standard ALD cycles

- Recipe database for high quality, tested processes

- Custom recipe input screen

- Real time display of process status

- Individually programmable heated source temperatures

- Built-in pulsing sequences for ternary compounds and nano-laminates

- Quick running with simple questions to get user going

- Input subcycles and overall cycles