The AT410 is the most cost-effective thermal ALD tool on the market.

Cost-Effective Thermal ALD

Designed for 4-inch substrates, the AT410 provides an affordable solution for thermal ALD applications. Its customizable chucks and chambers accommodate various sample types, including 3D parts, optics, electronic packaging or square substrates making it versatile for different research needs.

FEATURES

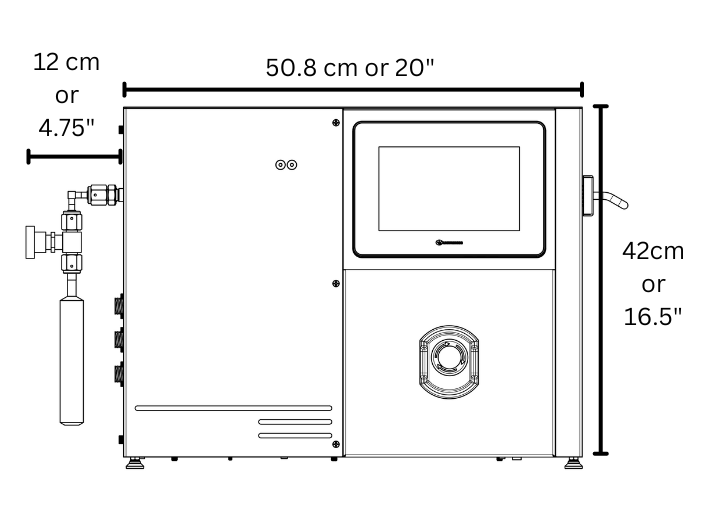

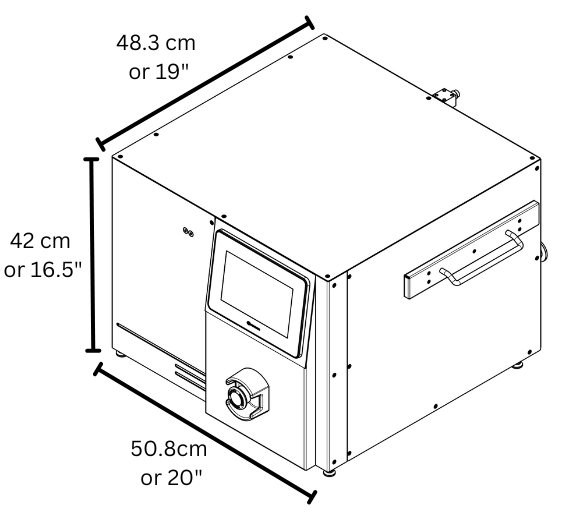

- Small Footprint Desktop System (< 0.15m3 | 2.5 sq ft)

- High temperature compatible fast pulsing ALD valves with ultrafast MFC for integrated inert gas purge.

- 4″ circular chuck customizable for smaller sizes or other shapes (11 mm tall).

- 3 organometallic precursors up to 175 °C and 2 (up to 3) counter reactants.

- Heated lines throughout (from precursor to chamber).

- High exposure (for trenches and porous substrates) and static processing mode

- All aluminum (semiconductor grade) chamber ‒ range up to 320 °C

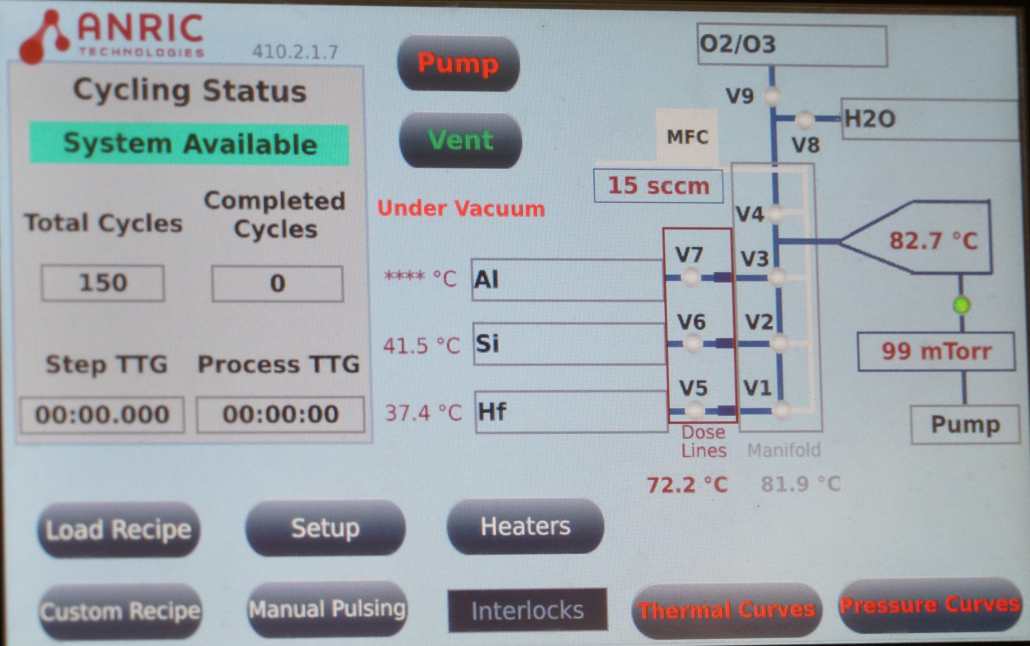

- 7″ touchscreen PLC controller (no PC required)

- Lifetime software upgrades included

- 1 year warranty

SPECIFICATION

- Chamber temperatures from RT to 320 °C ± 1 °C; Precursor temperatures from RT to 175 °C ± 2°C (w/ heating jacket)

- Smallest footprint on market (2.5 sq ft), bench top installation and cleanroom compatible

- Simple system maintenance and lowest utilities and precursor usage on the market

- Streamlined chamber design and small chamber volume

- Fast cycling capability (up to 1.2nm/min Al2O3) and high exposure, deep penetration processing available

- Full HW and SW interlocks for safe operation even in multi-user environment

OPTIONS

- Customized chuck/platen (square, indents for smaller pieces, batch)

- Customized chamber (thicker substrates, example: optical components)

- NEW Optional chuck to 450 + °C (ask us)

- NEW Available Hollow Cathode RF Source, 300 W Plasma (AT – 410 Plus)

- ATOzone – Ozone generator (required for some films: Pt, Ir, SiO2, MoO2, high quality Al2O3 below 60°C, high quality HfO2)

- Optional – Ozone Safety Monitor w real time detection of ambient ozone gas

- QCM (Temperature-compensating Quartz Crystal Microbalance)

- Glovebox integration (typically required to not expose substrate to moisture; Nitrides, Sulfides, etc..)

- External control – PC/software link (allows programing and running, remotely)

- Ventable Precursor cabinet

- Spare Chamber

- IGPA (inert gas pressure assist) for low vapor pressure precursors

- Third counter reactant

- Software control of third counter reactant

INSTALLATION

- For detailed instructions see our presentation and video instructions: “AT410/610 Installation and Start-up“

- N2 purge gas should be >99.9995% with a shutoff valve (regulated to 10 – 30 psi, metal sealed), .

- Input line is 1/4 female VCR compression fitting

- Attach > 99.9995% nitrogen (UHP) purge gas via 1/4″ metal line to the 1/4″ compression fitting on back

- Attach 90-110 psi CDA (clean dry air) via 1/4″ polyethylene tubing or metal line to the other 1/4″ compression fitting marked CDA (Clean Dry Air)

- Min 12cfm wet pump (**PTFE vacuum fluid (like Fomblin) required) (610 and 810 use larger pumps typically 19.5 cfm or higher)

- NW25 (KF25) (1″) connection and also exhaust line (with > 5cfm draw)

- Greater than 1 meter should use NW40 (1.5″) exhaust line

- Precursor’s attach via female VCR elbows (always use new gaskets).

- Elbow: 1/4″ gasket first (with gloves on)

- For precursor attachment please refer to AT410/AT610 Tool and Software Operation.

SOFTWARE

For detailed instructions see our presentation and video instructions: “AT410_610 Installation and Start-up“

- Human Machine Interface (HMI) PLC system with a 7” touch screen panel

- Advanced controls suitable for the deposition of standard ALD cycles as

- well as e.g. Nanolaminates, Doped Thin Films and Ternary Thin Films

- Recipe database for high quality, tested processes

- Custom recipe input screen

- Real time display of process status

- Individually programmable heated source temperatures

- Built-in pulsing sequences for ternary compounds and nano-laminates

- Quick running with simple questions to get user going

- Input subcycles and overall cycles