Equipment

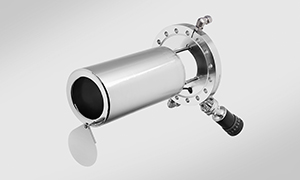

BFM Beam Flux Monitor

- Bayard-Alpert type ionization gauge

- Compatible with AML gauge controllers

- Mounting flange DN40 CF (O.D. 2.75")

- Linear gauge head positioning

- Standard linear travel 150 mm

- Bakeable up to 250°C

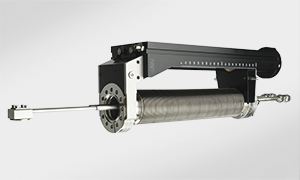

QCM Quartz Crystal Monitor

- Quartz crystal microbalance for thin-film measurements

- Compatible with most oscillator devices

- Mounting Flange DN40CF (2.75” O.D.), rotatable

- Linear travel 150 mm, 200 mm or 250 mm

- Bakeable up to 250°C

CS Cooling Shrouds

- Compatible with most MBE systems

- Highest welding and steel quality

- Different kinds of cooling shrouds

- Water or liquid nitrogen cooling

- Optional: integrated shutter

RMP Refractory Metal Parts

- All parts fully UHV compatible

- Highest quality and purity parts

- Custom-designed parts

- Standard Ta parts available

- All kinds of Ta screws and nuts

- Machined parts out of Ta, Ti, Mo, W

- Various PG and PBN parts

- Every 2D-geometry possible

- Material thickness up to 2mm

- Refractory metals like Ta, Mo, W

Crucibles

- All kinds of crucible shapes

- Wide range of crucible sizes

- Standard PBN crucibles

- Refractory and noble metal crucibles (W, Ta, Ir, etc.)

- Pyrolytic graphite (PG) crucibles

- Al2O3, BeO and MgO crucibles

Pyrolytic boron nitride (PBN) crucibles have become the accepted crucible material for use in MBE growth of semiconductor materials because of the material's high purity, chemical inertness, thermal stability, low outgassing, non-wetting characteristics and long lifetime.

PBN can be used for temperatures up to 1500°C. The maximum temperature decreases with rising chamber pressure.

For higher temperatures or for special applications crucibles made of other materials like tungsten (W), tantalum (Ta), pyrolytic graphite (PG), silicon dioxide (quartz), aluminum oxide (Al2O3), beryllium oxide (BeO), or magnesium oxide (MgO).

Other crucible materials are available on request.

For higher temperatures or for special applications crucibles made of other materials like tungsten (W), tantalum (Ta), pyrolytic graphite (PG), silicon dioxide (quartz), aluminum oxide (Al2O3), beryllium oxide (BeO), or magnesium oxide (MgO).

Other crucible materials are available on request.

PS Power Supply and Temperature Control

- High quality DC power supplies

- Constant voltage and current control

- Programmable power supplies and PID controllers

- High efficiency and long lifetime

- Industrial standard components

- Modular design

- 19" rack system compatible

CA Cables and Connectors

- Solutions for all connections

- Cleanroom compatible

- Power cables for currents up 100 A

- Various cross-sections and lengths

- Thermocouple extension cables

- High-temperature bakeable cables and connectors up to 300°C

MCU Manipulator Control Unit

- Precise substrate rotation control

- Brushless motor for high reliability and constant speed under variable load

- Manual or remote operation

- 19" rack system compatible

PMCU Programmable Manipulator Control Unit

- Precise control of substrate rotation, substrate lift position (height) and angular position

- Manual operation or remote operation per analog signal or serial interface

MVCU Motorized Valve Control Unit

The Motorized Valve Control Unit (MVCU) provides the power and control for the stepper motor drive which moves the mechanical valve mechanism inside a valved effusion cell.

Manual and remote control of the valve position as well as an automated calibration of the zero position (valve closed) is available by the touch screen monitor on the front panel of the MVCU controller.

In “Remote Mode” the valve position can be set by an external voltage (0...10 V DC) after calibration of the MVCU.

A special Valved Shutter operation mode (VS) allows acting the MVCU similar to a simple shutter unit. Therefore the valve is opened to a position, selected by the user and closed by an external digital signal from a shutter control unit (SCU) or process control computer.

CVCU Cryopump Valve Control Unit

The Cryopump Valve Control Unit CVCU is a safety system which protects UHV-chambers from contaminations caused by unexpected warming up of the cryopump. This event can result from compressor or cryopump faults as well as from sudden cooling water or electrical power shutdowns.

The CVCU requires a cryopump cold head temperature sensor and an electro-pneumatic valve with integrated valve state sensor to separate the cryopump from the UHV-system.

During regular operation the temperature of the cryopump cold head is shown on the display of the CVCU as well as the current true state of the valve is shown by the LED. The valve is operated by the "OPEN" and "CLOSE" buttons on the front side of the CVCU.

In case of sudden power shutdown or a warming up of the cryopump above a temperature setpoint, the valve is closed immediately and remains closed until it is opened manually.

The CVCU housing is compatible to the 19" rack system.

The CVCU requires a cryopump cold head temperature sensor and an electro-pneumatic valve with integrated valve state sensor to separate the cryopump from the UHV-system.

During regular operation the temperature of the cryopump cold head is shown on the display of the CVCU as well as the current true state of the valve is shown by the LED. The valve is operated by the "OPEN" and "CLOSE" buttons on the front side of the CVCU.

In case of sudden power shutdown or a warming up of the cryopump above a temperature setpoint, the valve is closed immediately and remains closed until it is opened manually.

The CVCU housing is compatible to the 19" rack system.