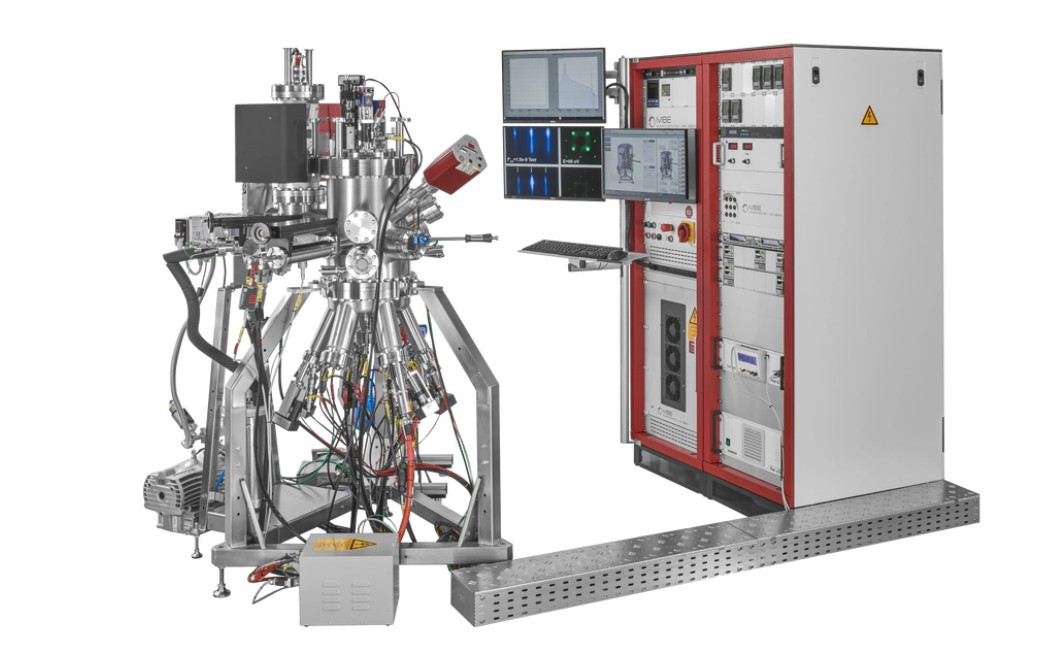

Mini III/V, II/VI, topological insulator or other material MBE system

- Compact and versatile research MBE system with small footprint

- Applications: II-VI, III-V, IV-IV, metals, magnetic materials, topological insulators, nanowire growth, oxides, organic materials

- 9 source ports DN40CF (O.D. 2.75’’) or 8 source ports (2x DN63CF (O.D. 4.5’’), 6x DN40CF (O.D. 2.75’’))

- Wide range of source options

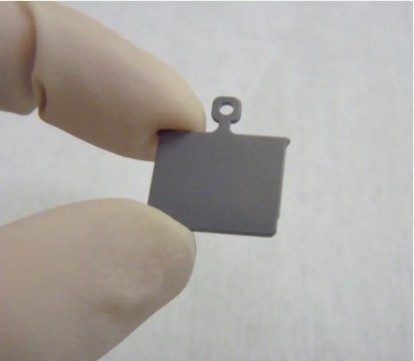

- Sample size : flag style 10x10 mm2 , 1’’ or 2’’ wafer

- Effective UHV pumping system

- Stainless steel LN2 cooling shroud

- Low energy and LN2 consumption

- In-situ monitoring capability

- Professional support by PhD MBE experts

General Information

The OCTOPLUS 300 system is ideally suited for material deposition on small samples. It provides good access and easy operation and maintenance. The chamber design of the OCTOPLUS 300 plus various state-of-the-art components allow layer by layer precise MBE growth.

Outstanding features of the OCTOPLUS 300 are the high reliability and versatility of the system and its small footprint. These features make the OCTOPLUS 300 system particularly suited for applications in research and development. Nonetheless specific production processes are also covered.

The standard version of the OCTOPLUS 300 comprises 8 source ports, two ports with 4.5 inch (DN63CF) and six ports with 2.75 inch (DN40CF) flange size. By using Source Clusters up to 10 sources can be integrated into the system. A rapid pump-down load lock chamber with a horizontally working transfer-rod system allows the user an easy substrate introduction without breaking the vacuum of the MBE chamber.

We provide different kinds of effusion cells, valved cracker sources, gas sources and substrate manipulators according to all our customers' requirements. A well-manageable in-situ characterization is obtained by using beam-flux-gauges, pyrometers, RHEED systems or quadrupole mass analyzers (QMA).

Options for OCTOPLUS 300

- Additional load lock or buffer chambers

- Wafer transfer system

- 2 cm³, 10 cm³, 35 cm³, 60 cm³ effusion cells, source clusters, electron beam evaporators, cracker and valved cracker sources, manipulators, power supplies and control units

- Pumping system (ion getter pumps, turbopumps, cryopumps etc.)

- Control system

- In-situ characterization tools, e.g. ion gauge, Quartz Crystal Microbalance (QCM), pyrometer, RHEED, QMA

Technical Data

|

Size of deposition chamber |

300 mm I.D. |

|

Base pressure |

< 5x10-11 mbar |

|

Pumping |

turbopump, ion getter pump and TSP |

|

Cooling shroud |

LN2 or water cooling |

|

Substrate heater temperature |

up to 1200°C |

|

Substate size |

small sample plates or up to 2" wafers |

|

Bakeout temperature |

up to 200°C |

|

Source ports |

9 ports DN40CF or 8 ports (2xDN63CF, 6xDN40CF) |

|

Source types |

effusion cells, e-beam evaporators, sublimation sources, valved cracker sources, gas sources |

|

Shutters |

soft-acting rotary shutters |

|

In-situ monitoring |

ion gauge, QCM, pyrometer, RHEED, QMA |

|

Sample transfer |

linear transfer rod (manual) |

|

Load lock |

magazine with 6 substrates turbo-pumped |

|

MBE control software |

Tiny Tusker |

|

Service |

system installation and acceptance testing |

|

MBE training |

by MBE experts |

Examples for applications and corresponding sources

|

|

Plasma Sources |

E-Beam |

|||

|

III/V |

Ga, In, Al |

C, Si doping |

As, P, Sb |

|

|

|

II/VI |

Zn, Cd, Be |

|

S, Se, Te |

N-doping |

|

|

IV |

Ge, Sn, Pb |

B, P, Sb doping |

|

|

Si, Ge |

|

GaN |

Ga, In, Al |

|

|

N |

|

|

Metals |

Cu, Al, Ni, Co, ... |

|

|

|

Pt, Ta, Pd, Mo, W |

|

Topological Insulators |

Ge, Sn, Te, Bi, GeSb |

|

Se, Te |

|

B |

|

Graphene / Silicene |

|

C, Si |

|

|

|

|

Oxides |

Fe, Ni, Mn, Bi, Eu, |

|

|

O |

|

|

Thin Film Solar Cells |

Cu, Ga, In, Zn, NaF, |

|

S, Se |

|

|