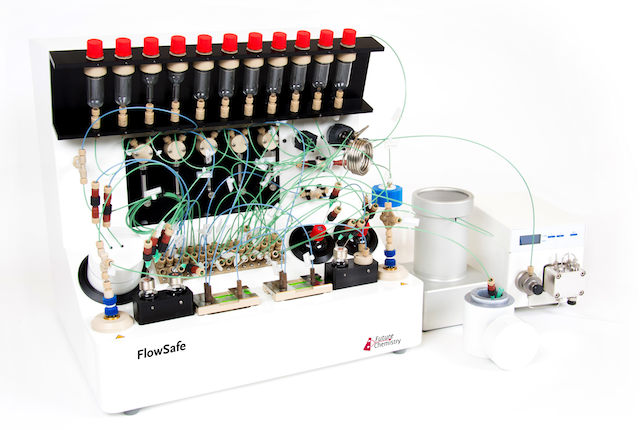

The FlowSafe is a compact, advanced system for the production of new and routine PET-tracers and retains the benefits of flexibility and ease-of-use of the instrument. The FlowSafe automates production of PET tracers, using an 18F solution directly from a cyclotron target or 18F trapped on cartridges.

Benefits of the FlowSafe

- Fully automated production of standard radiotracers e.g. 18F-FDG, 18F-FLT, 18F-MPPF and 18F-FMISO

- Advanced controlled drying of 18F

- Integrated design: no large external housing for e.g. cooling, heating and control electronics

- design for excellent serviceability

- Plug ‘n Play

- Low operational costs due to re-using of wetted parts

- Flexible design allows combining drying, reacting, purifying and formulating steps yielding a ready-to-use PET-tracer

- Batch reactors and flow microreactors: combining best of both worlds FlowSafe’s two microreactor stations enable

- Synthesis above boiling point of solvent

- High control over reagents gives access to shorter reaction times and increased reliability and reproducibility

- Shorter reaction tmes allow working with instable precursors and intermediates

Leading the way in PET tracer production and development. The FlowSafe automates production of PET tracers, using an 18F solution directly from a cyclotron target or 18F trapped on cartridges.

Four independent reaction stations allow separate control over drying, fluorination, deprotection and formulation.

Comecer Absynth software enables you to get up a fully cGMP workflow: Built-in audit trail, user controlled access, history of synthesis development and logging of all process parameters during a production. All data and actions are fully registered.

Specifications

| Dimensions (w x d x h) | 465 x 424 x 372 mm |

| Weight | 28.5 kg |

| Control electronics | All integrated into synthesizer |

| Program control | By PC software (Comecer Absynth) |

System components

| Components Included | 2 Batch reactor stations up to 200°C |

| 2 microreactor stations 1 to 140°C | |

| Back pressure regulator | |

| Pressure sensor | |

| Vacuum pump with vacuum sensor | |

| Liquid dosing systems for accurate control | |

| SPE cartridge holder | |

| 11 liquid reservoirs |

Electrical specifications FlowSafe

| Voltage | 110-120 VAC/60 Hz or 220-230 VAC/50 or 60 Hz |

| Power consumption | <770 W |

HPLC integration

| Components Included | HPLC pump |

| HPLC injector valve | |

| HPLC injection loop | |

| HPLC column | |

| HPLC radioactivity detector |