ISO 4589-3, NES715

Oxygen Index Module은 시료의 OI 및 LOI, COI와 같은 산소지수를 측정하는 기기이며, Temperature Index는 고온에서 재료의 산소지수를 측정하는 확장된 Oxygen Index Module입니다. 일반적으로 가스 혼합물이 가열되면서 산소지수는 낮아지기 때문에 상온에서 수행된 결과는 더 높은 고온에서 보완되어야 합니다. Concept Equipment사의 Temperature Index Module은 가장 최근의 제어기술을 채용했으며, 터치스크린을 통해 다양한 변수를 쉽게 선택할 수 있어서 시스템은 지능적으로 구동됩니다. 즉, 수동으로 가스밸브를 조절하는 대부분의 불편한 기기와는 다른 특성을 제공합니다.

Specification & Features

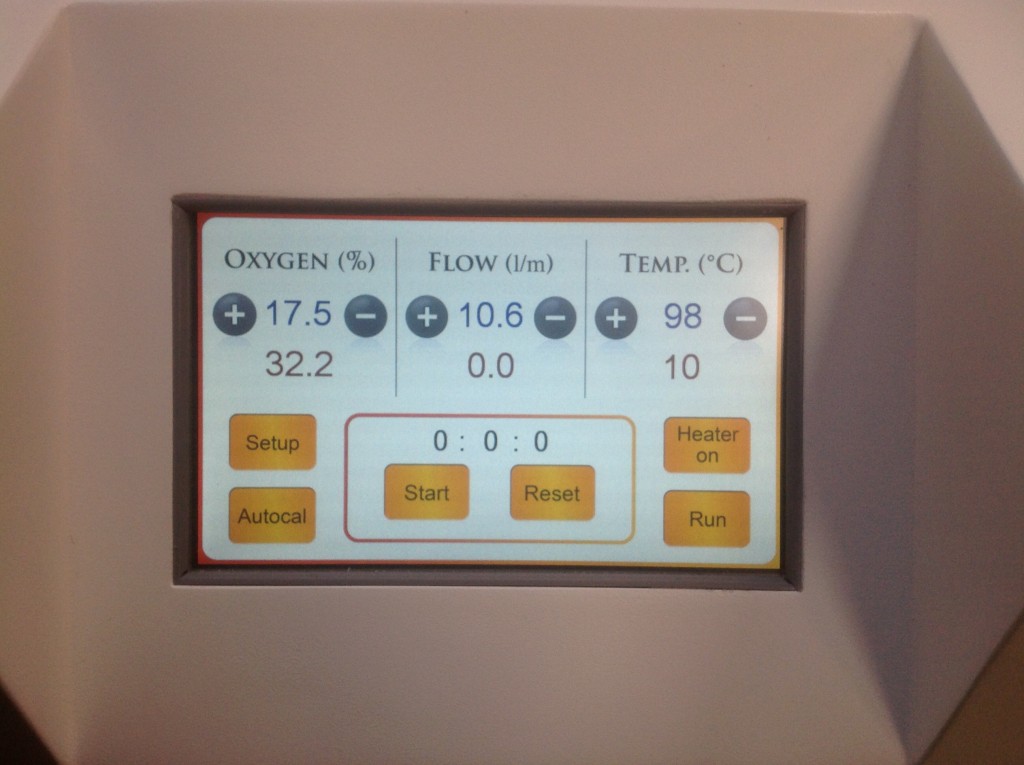

- It is simple to use, like the OIM, and utilises easy to read digital displays, indicating the oxygen index directly in % Oxygen, as well as the flow rate in nl/min, column temperature in °C and extensive instrument status.

- A state of the art oxygen transducer, accurate to ±0.1%, is used for measurements.

- A low noise air pump is used to supply air into the test chamber to allow the column temperature to be pre-set, prior to switching over to the oxygen/nitrogen mix for the test run, thus minimising use of cylinder gases and protecting the heating elements.

- A dual heater system is used to ensure a stable and uniform temperature around the sample.

- The sample heater temperature is displayed on the digital screen. The system intelligently controls both heaters such that individual adjustment of column and pre-heater temperature on every use, is not required.

- The heated column design allows maximum visual observation of the test.

- The system also monitors the gas to ensure that if the combustion mixture flow fails during a run, the power to the heaters is removed and an alert is displayed.

- The measured sample temperature is achieved using an adjustable temperature probe which can be positioned inside the heated column adjacent to the sample.

- Calibration of the instrument is fully automatic. The “Autocal’’ push button is selected on the display panel and calibration at zero % and maximum range oxygen, is then performed automatically by the instrument, without the necessity of manual ‘trimming’, as with other instruments.

- Ideal for use in quality control applications as well as a tool for the development and analysis of new materials.

Technical Data & Requirements

- Electrical: 230 VAC 50Hz / 115V 60Hz

- Operating Temperature: 10°C to 35°C.

- Test Temperature: Ambient to 400°C.

- Dimensions: 450mm (W) x 800mm x (H) x 450mm (D).

- Flow: Flow through column adjustable from 0 to 20 nl/min.

- Gas Supplies: Oxygen and Nitrogen at 2.6 Bar (38 psi) minimum. Minimum flow to Oxygen and Nitrogen pipe lines 25 nl/min. (normally bottled supply with in-line regulator and filter). No other restrictions should be used as this will reduce the flow rates. Propane at 0.1 ~ 0.5 Bar.

- Oxygen Analyser: Range: 0 to 100% Oxygen, Repeatability (typical):± 0.1% Oxygen, Linearity (typical):± 0.1% Oxygen

The Temperature Index extends the range of the Oxygen Index Module, so that the oxygen index of materials can be measured at elevated temperatures.

Generally, the oxygen index falls as the gas mixture is heated, so work at elevated temperatures supplements work carried out at room temperature.

This new model available from Concept Equipment utilises the very latest control technology. Selection of all variable elements is by easy touchscreen selection and the intelligent system adjusts accordingly. This differs from most competitive products, where valves need to be adjusted manually, which is a time consuming and tedious task.