ISO5659-2, BS6401, ASTM E662, IMO FTPC PART 2, NES711, BSS 7239, AITM 3.0005, AITM3.0005, ABD0031

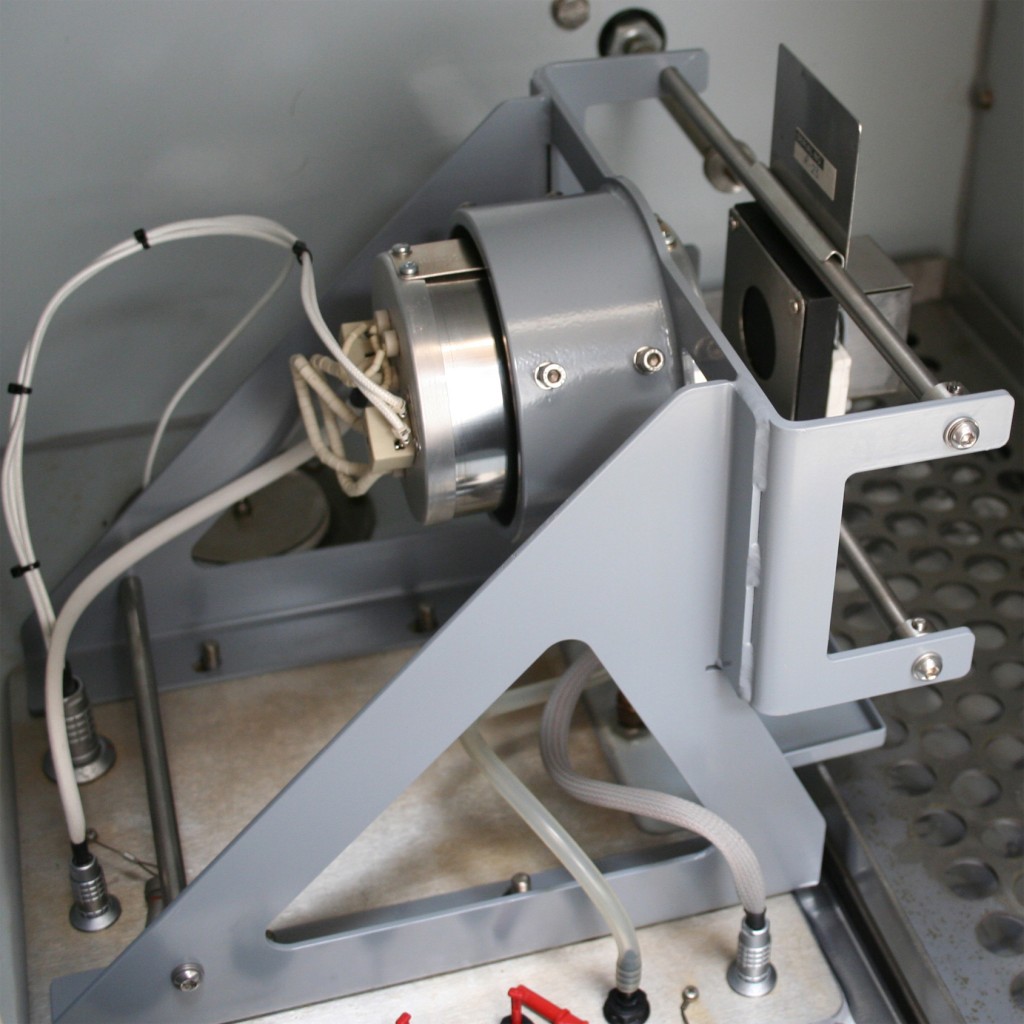

Smoke Chamber는 1980년대에 시작된 이래 가장 다재다능한 화재 테스트 장비 중 하나로 입증되었습니다. BS6401 및 ASTM E662를 준수하는 수직 테스트 구성이 전통적으로 사용되어 왔으습니다. 이 방향은 FAA 테스트에도 사용됩니다. 가장 최근의 수평 구성은 아래 이미지 중 하나입니다. 샘플은 conical heater에 의해 수평면에 노출됩니다. 이 테스트 방법인 ISO 5659 Part 2는 플라스틱 평가 및 해양 및 철도 애플리케이션에 널리 사용되는 제품입니다.

최근의 EN 45545-2 유럽 철도 차량 화재 테스트 표준(European rolling stock fire testing standard)은 제품 및 재료의 인증을 위해 철도 산업에서 사용되는 test method 그룹의 일부로 ISO5659-2를 채택했습니다. 또한 Smoke Chamber는 BSS 7239 및 AITM 3.0005 방법을 준수하는 독성 챔버 (toxicity chamber) 옵션을 사용하여 독성 측정에 활용할 수 있습니다.

Specification & Features

- The most widely accepted apparatus for the measurement of smoke from burning materials.

- The instrument measures specific optical density under flaming and non-flaming conditions. It is also used for the extraction of toxic gas.

- The Concept Smoke Chamber incorporates all the necessary features and software needed to complete tests, in as simple, ergonomic and user friendly way as possible.

- The user can choose the configuration required such that the equipment complies with the mandatory requirements of BS 6401/ASTM E662 or ISO5659-2, or hot swappable between both apparatus specifications.

- Standard stainless steel chamber with additional corrosion resistant finish.

- Heated chamber walls.

- Full size chamber door, including an observation window and covering door.

- Instrument panel to left of chamber for ease of operation.

- Fixed irradiance vertical oriented heater (25kW/m²).

- Vertical photometric optical system using state of the art PMT module (mandatory).

- Push button/software controlled sample positioning system.

- Push button/software controlled pneumatic lower vent assembly with high capacity extraction fan to efficiently extract smoke following a test.

- Push button/software controlled pneumatic upper vent.

- Multi-tip, multi-angle stainless steel pilot burner.

- Precise furnace control allowing software controlled furnace calibration.

- Bespoke radiometer for furnace calibration as per BS6401 and ASTM E662.

- Easy to replace blow-out panel.

- Built in ports to take gas sampling tubes.

- Control and data acquisition system including DAQ hardware, Laptop and extensive software package.

- Full operating instruction manual.

Technical Data & Requirements

Electrical: 110V AC 60Hz / 230V AC 50Hz

Ambient Temperature: Operating 10°C to 35°C

Dimensions: 1560mm (W) x 2220mm x (H) x 1060mm (D-incl. laptop)

Gas Supplies: The preferred fuel gas used in the test is a mixture of air & propane.

- Propane: The flow needs to be capable of delivering 20ml/min at a minimum pressure of 5 KPa.

- Compressed Air: The flow needs to be capable of delivering 750ml/min at a nominal pressure of 400 Kpa. This is required to obtain flame stability for testing.

ISO5659-2, BS6401, ASTM E662, IMO FTPC PART 2, NES711, BSS 7239, AITM 3.0005, AITM3.0005, ABD0031

The Smoke chamber has proved to be one of the most versatile fire testing instruments since it’s inception in the 1980’s. It’s vertical testing configuration, conforming to BS6401 and ASTM E662, has traditionally been the arrangement used and is shown in the images on this page. This orientation is also used for FAA testing. The more recent horizontal configuration is as shown in one of the thumbnails on the left. The sample is exposed in the horizontal plain by a conical heater. This test method, ISO 5659 Part 2, is widely used in the evaluation of plastics and for products used in marine and railway applications. The recent EN 45545-2 European rolling stock fire testing standard has adopted ISO5659-2 as part of the group of test methods to be used in the railway industry for the certification of products and materials. In addition the smoke chamber can be utilised for toxicity measurements using our toxicity chamber option, which is compliant with methods BSS 7239 and AITM 3.0005.