EN ISO 1182, ISO1182, IMO FTPC PART 1, ASTM E 2652

EN ISO 1182 불연성 시험은 일련의 Euroclass 시함 규격 중 하나입니다. 이 시험은 재료가 화재 발생에 직접적으로 기여하는지 여부를 결정하는 절차를 지정하고, 바닥재를 포함해 모든 건축재를 A1 및 A2의 등급으로 분류하는 것과 관련이 있습니다.

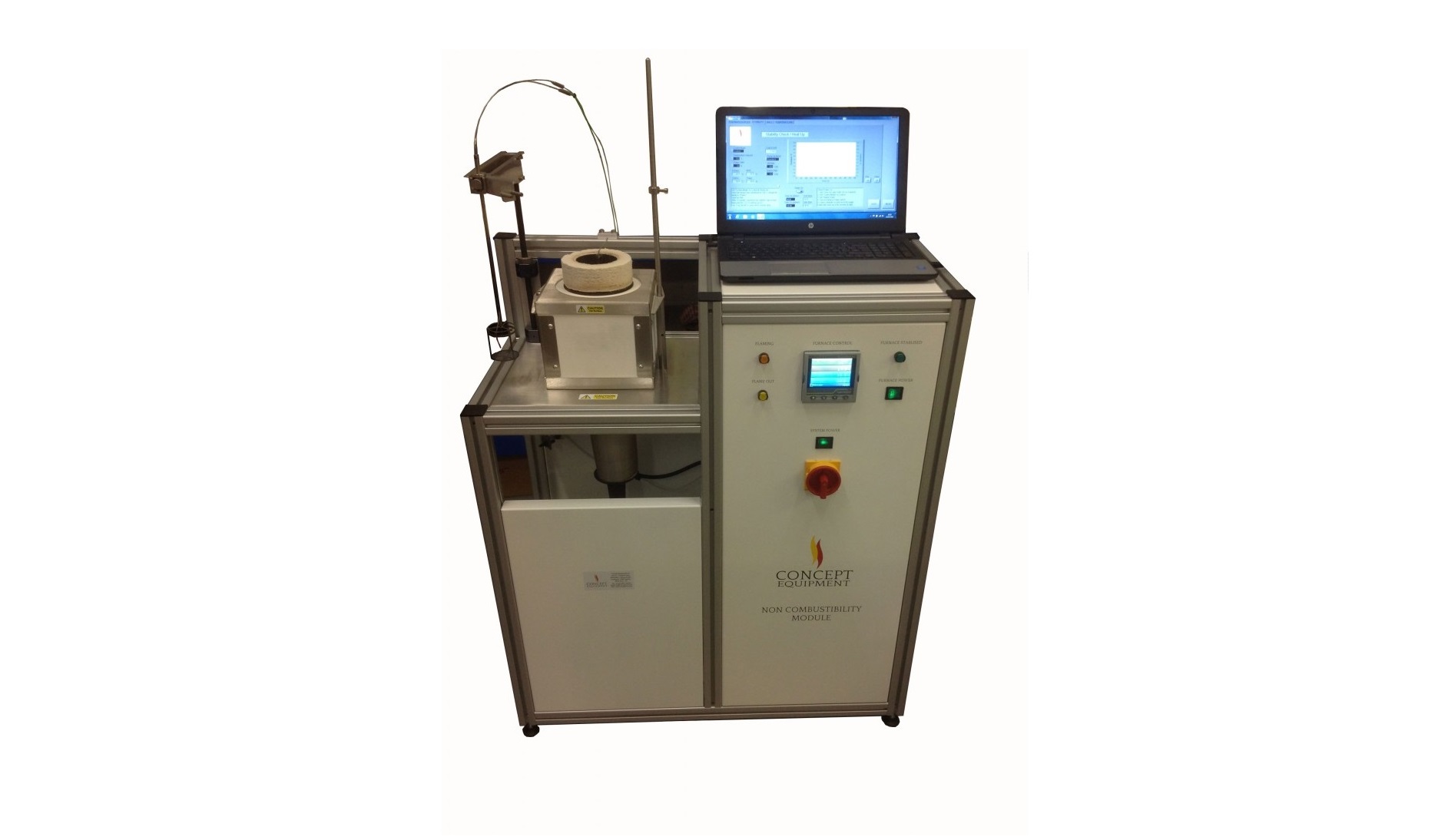

퍼니스 어셈블리는 프레임에 장착된 절연 서라운드 내의 전기식 가열 수직 퍼니스 튜브로 구성되며, air flow stabiliser와 draught shield, screen을 포함합니다. 본 장비는 시료 홀더와 시료 삽입 장치, 3 개의 온도센서(thermocouple)가 함께 제공됩니다. 온도센서 하나는 퍼니스 벽 온도를 측정하기 위한 것으로, 또 하나는 샘플 내부 중앙에 위치하며, 다른 하나는 standard에 명시된 대로 샘플 위치의 한 쪽 온도를 측정합니다. Thermocouple positioning support와 EN 표준에서 요구하는 새로운 온도 센서(Thermal Sensor)도 포함됩니다. 이 장치는 또한 ISO 1182의 요구 사항을 준수하도록 설계되었습니다.

Concept Equipment사는 표준화된 ISO 1182 퍼니스를 제어하고 효과적이고 사용자 친화적 인 DAQ 솔루션을 제공하기 위해 데이터 수집 및 소프트웨어 패키지와 결합된 고급 온도 제어 시스템을 제공할 수 있습니다. DAQ 솔루션은 종전의 매뉴얼 전원 설정 및 차트 기록 시스템을 현대적인 최신 기술로 대체하였습니다.

Specification & Features

Control module features:

- Custom frame with integrated control module

- Stabilised power supply providing constant voltage to the furnace windings

- Advanced automatic furnace conditioning, temperature measurement, test monitoring and data acquisition

- Furnace wall, sample centre and sample surface thermocouples

- Stainless steel specimen holder and specimen insertion device

- Digital display/interface indicates furnace, sample and sample surface temperatures

- Air flow stabiliser, draught shield and screen

- The system also calculates the average/maximum temperature and drift values and updates the display every 5 seconds

- Single ‘push button’ furnace conditioning

- Grooved design furnace assembly

- Unique ‘first time heating’ cycle,allowing controlled heating of new furnaces at 100°C/ hour

- ‘Calibration’ cycle to allow calibration of the furnace, as specified in the standard

- Test monitoring to identity stabilisation of sample. Once achieved, the system automatically indicates the end of test

- High scan rate Data Acquisition including: recording and display of all temperatures against test time, Calibration routines, event marking of material behaviour on data

- Windows XP, Vista & 7 compatible software including extensive on screen data acquisition. Easy raw data exchange into MS Excel to allow report generation in MS Word and Excel. MS Word and Excel are not included

- Optional Handset to allow remote operation of the instrument and push button recording of flaming events. This signal is time stamped and transmitted to the data acquisition module

- Thermal sensor as required in the EN standard is also included

Technical Data & Requirements

- Electrical: 230 volts – Nominal 10 Amps

- Ambient Temperature: Operating 10°C to 35°C

- Dimensions: Apparatus, including control system – 900 mm (W) x 1300 mm x (H) x 400 mm (D)

EN ISO 1182, ISO1182, IMO FTPC PART 1, ASTM E 2652

The EN ISO 1182 Non-combustibility test is one of the series of Euroclass test standards. This test specifies a procedure for determining whether or not a material will contribute directly to fire development and is relevant to classification of all building products (including floorings) into classes A1 and A2.

The furnace assembly consists of an electrically heated vertical furnace tube within an insulated surround which is mounted on a frame, which includes an air flow stabiliser, draught shield and screen. The apparatus is provided complete with a specimen holder, a specimen insertion device and three thermocouples. One for measuring the furnace wall temperature, one positioned centrally inside the sample and one positioned to one side of the sample position as stipulated in the standard. Thermocouple positioning supports are also included. The new Thermal Sensor as required in the EN standard is also included. The apparatus is also designed to comply with the requirements of ISO 1182.

Concept Equipment are able to offer a high end temperature control system coupled with a data acquisition and software package to control the standardised ISO 1182 furnace and provide an effective and user friendly DAQ solution. This DAQ solution offers a modern replacement to the manual power setting and chart recorder systems previously used with this apparatus.