FAR Part 25 App F Part I (Vertical, Horizontal, 45° and 60°), AITM 2.002, 2.003, 2.004, & 2.005, BSS 7230: F-1, F-2, F-3, F-4, F-5, & F-6

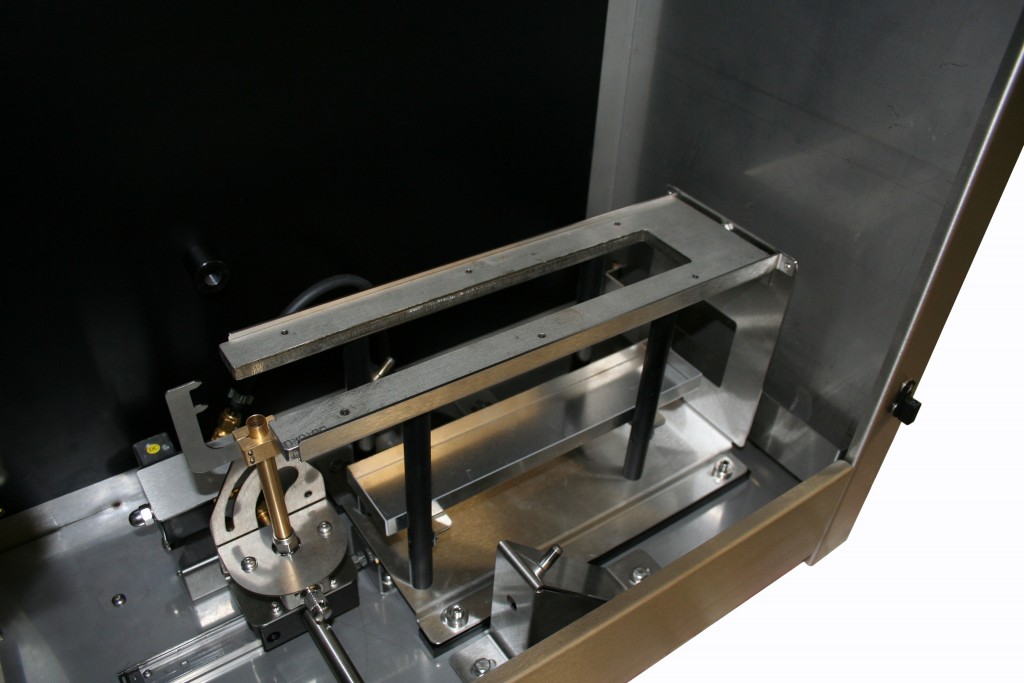

FAA 4C test method는 항공기 또는 여러 관련 차량에 사용되는 내장재의 연소 거동을 평가하는 데 사용됩니다. 작은 화염에 노출되었을 때 재료의 화염 전파(flame propagation)와 화염 시간 후를 결정하는 데 사용됩니다. 기기의 모듈형 설계로써, 기준면에서 수평, 수직 , 45°에서 테스트 할 수 있습니다. 60° 케이블 테스트도 포함됩니다.

네 가지 테스트가 모두 표준 FAA-4C 장비에 포함됩니다. 그러나 다양한 조합이 가능하며 고객 요구 사항에 따라 공급할 수 있습니다. 예를 들어 필요 시 기기를 수평 및 수직 구성으로만 제공됩니다. 한 구성에서 다른 구성으로 전환하는 데 1 ~ 2 분 정도만 소요되며, 시험 간 설정 시간을 최소화합니다.

The apparatus is bench mounted, ergonomically designed and simple to use and is ideal for use in quality control applications. The cabinet is fabricated out of high quality brushed stainless steel and offers automatic start test and a digital timer which automatically controls gas flow and records timed events.

A wall mounted variable speed extraction hood is also available as an option to assist in evacuating the contents of the chamber during and after testing.

This latest addition to our range of aviation test equipment fully complies with FAA, Airbus and Boeing specifications and reflects the recent changes to the FAA handbook test specifications.

Specification & Features

- Test chambers according to FAR Part 25: Horizontal, Vertical, 45′ and 60′ tests

- Cabinet fabricated from high quality stainless steel

- Adjustable burner position from front

- Automatic starting of test when burner is placed in test position

- Selectable and automated flame application time

- Enables ‘after flame’ and ‘dripping’ timings to be recorded

Technical Data & Requirements

- Electrical: 230 volts AC 50Hz, 2 Amp / 115volts AC 60Hz, 4 Amp

- Ambient Temperature: Operating 10°C to 35°C

- Burner Gas Supply: The preferred fuel gas used in the test is methane with a minimum purity of 99%.The pressure required to obtain flame stability is approximately 17.2 kPa (2.5 PSI). Other gases may be used but they must have a calorific value of approximately 38 MJ/m3.

- Effluent removal: An extraction hood is recommended to be situated above the chamber to take away any smoke effluent produced during testing. We advise a variable flow extraction rate adjustable between of 0-300 m3 /hour. The minimum hood size 850 mm wide x 400 mm deep is recommended. The chamber can also be placed inside a fume cupboard if required. A wall mounted variable speed extraction system is available as an option to assist in evacuating the contents of the chamber during and after testing. Please ask contact us for further details.

- Dimensions: 752 mm (W) x 832 mm x (H) x 330 mm (D)

- Packed Weight: 60Kg

FAR Part 25 App F Part I (Vertical, Horizontal, 45° and 60°), AITM 2.002, 2.003, 2.004, & 2.005, BSS 7230: F-1, F-2, F-3, F-4, F-5, & F-6

The FAA 4C method of test is used to assess the burning behaviour of internal materials used in aircraft or other related vehicles. It is used to determine the flame propagation and after flame time of materials when subjected to a small flame. The modular design of the instrument allows testing in the horizontal, vertical and also at 45° to the datum plane. A 60° cable test is also included.

All four tests are included with the standard FAA-4C instrument. However, different combinations are possible and can be supplied to customer requirements. For example, the instrument is available with just the horizontal and vertical configurations. Switching from one configuration to another takes just a minute or two, with minimal set up time between tests.