XRD-2700 시리즈 X-선 회절 분석기는 재료 연구 및 산업 제품 분석을 위해 설계되었으며 종래의 분석 기술과 특수 목적 측정 기법을 결합한 완벽한 제품입니다.

- The perfect combining with hardware and software system, satisfy with the requirement of different application field academician, scientific research.

- High precision diffraction angle measuring system, obtaining more accurate measurement results.

- High stability X-ray generator control system, and get more stable repeatable measurement precision.

- Various functional accessories meet the requirement of different testing purposes.

- Program operation, integrated structure design, easy to operate, more beautiful appearance of the instrument;

- X-ray diffractometer is a kind of universal testing instrument for revealing crystal structure and chemical information of material:

- One and many phase identification of unknown sample

- Quantitative analysis of the phase in the mixed sample

- Crystal structure analysis (Rietveld structure analysis)

- The crystal structure change (high temperature and low temperature condition) of the abnormal condition.

- Thin film sample analysis, including film, multilayer film thickness, surface roughness, charge density.

- Analysis of micro area sample.

- Texture and stress analysis of metallic materials

Application

본 제품은 금속 재료 및 유.무기 재료, 복합 재료, 나노 소자, 초전도 소재에 적용 할 수 있습니다. 이들 재료 상태는 분말 또는 블록, 박막 및 마이크로 영역의 마이크로 샘플 일 수 있습니다. 본 제품은 점토 광물, 시멘트 건축 자재, 환경 먼지, 화학 제품, 약물, 석면, 암석, 폴리머 및 다양한 연구 분야에서 널리 사용됩니다.

Functions

- Indicate the material’s crystal structure and chemical information;

- Identify one or multiple phases in an unknown sample;

- Quantitative analysis of the known phase in the mixed sample;

- Crystallographic structural analysis (Rietveld structure analysis);

- Measure the changes of crystal structure under normal conditions (low or high temperature);

- Film sample analysis, including thin film phase, multi-films thickness, surface roughness and electric density;

- Micro-area sample analysis;

- Microstructure and stress analysis on metal material.Optional Multi-sample holder

Advantages

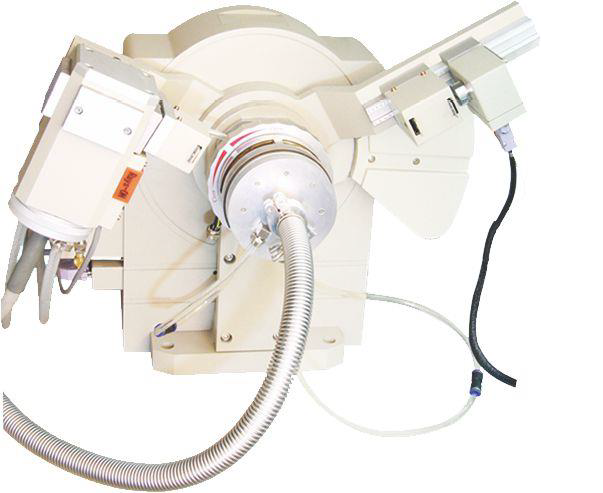

- Base on θ-θ optical design it is easy for sample preparation and accessories installation;

- Adopting metal ceramic X-ray tube improves the operating power of the XRD greatly;

- Closed proportional counter is durable and maintenance free;

- Silicon Drift Detector has superior angular resolution and energy resolution, the measuring speed can improve more than 3 times;

- Various accessories can meet different analysis aims; Various function accessories automatic identification;

- Base on modular design (plug and play configuration), operator can correctly use XRD without adjusting optical system.

Function of Software

- Basic data processing (peak seeking, smoothing, background deduction, peak fitting, peak amplification, spectra comparison, Kα1 and α2K stripping, diffractive line indexing, etc.)

- Quick quantitative analysis for samples without and reference parameters;

- Size measurement of crystal grain;

- Crystal structure analysis (parameter measurement and refining of unit cell);

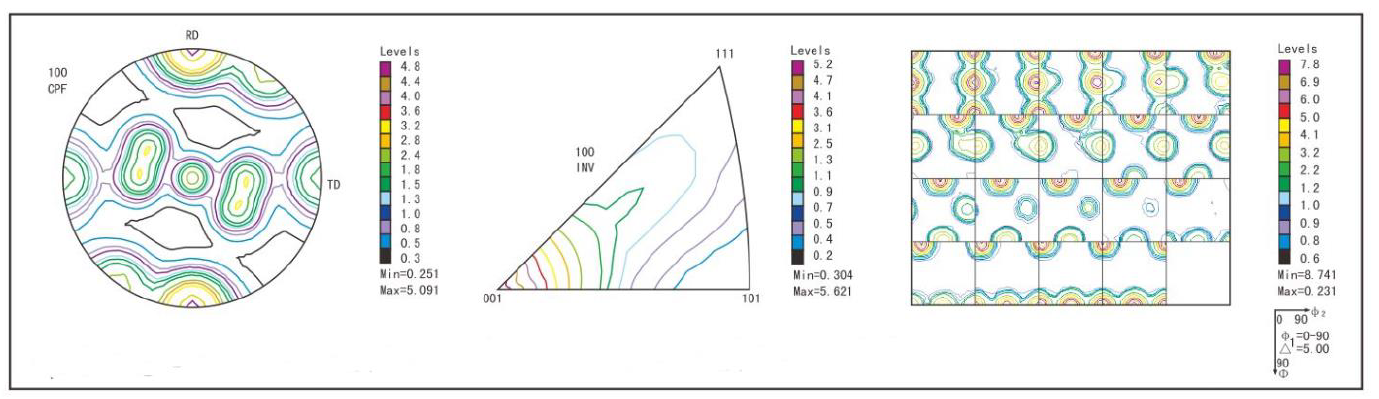

- Macroscopic stress measurement and micro stress calculation; 2d and 3d display of multiple drawings;

- Diffraction peak image cluster analysis;

- Diffraction data half-peak width correction curve;

- Diffraction data Angle deviation correction curve;

- General quantitative analysis Based on Rietveld;

Multi-function sample holder

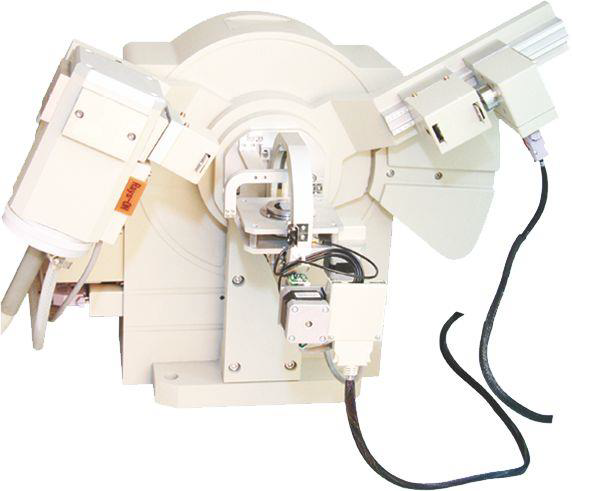

With the deepening of material analysis, we want to do performance analysis by XRD on more materials, such as slabs, bulk material and film on matrix. Installing a multi-function sample holder on the goniometer can realize texture, macro-stress and film inner structure measurements. Each function has its own calculating software.

➢Texture measurement and evaluation on rolling plate (AL, Fe, Copper plate, etc)

➢Texture measurement and evaluation on rolling plate (AL, Fe, Copper plate, etc)

➢Residual stress measurement on metal, ceramic, etc

➢Crystal preferred orientation evaluation on film sample

➢Orientation measurement on macromolecular compound

➢Multilayer film, oxidation film and nitride film analysis on the metals and non-metallic substrate

Multi-function sample holder is used for structure measurement, after calculation, it will draw out pole figure, inverse pole figure and ODF figure. Multi-function sample holder is used for macroscopic stress measurement. Set several Psi angles between -30-90° to make the sample tilt corresponding angles. At different Psi angles, it can measure angle deviation of specific crystal plane respectively and figure out the macro-stress of the sample.

Specification

|

|

XRD-2700A |

XRD-2700B |

|

Rated power |

3kW (HF, HV control technology) |

4kW |

|

Tube voltage |

10~60kV |

|

|

Tube current |

5~50mA |

5~80mA |

|

X-ray tube |

Metal ceramic tubeTarget material: Cu、Fe、Co、Cr、Mo, etc Power:2.4kW |

|

|

Focus size |

1×10mm or 0.4×14mm or 2×12mm |

|

|

Stability |

≤0.005% |

≤0.01% |

|

Goniometer structure |

Sample level(θ~θ) |

|

|

Radius of diffraction |

225mm(or custom by request:150~285mm range) |

|

|

2θ Scanning range |

﹣6~160°(θs:﹣3~80°、θd:﹣3~80°) |

|

|

Scanning speed |

0.0012°~50°/min |

|

|

Scanning fashion |

θs/ θdlinkage /single acting; continuous, stepping and Omg |

|

|

Minimal stepping angle |

1/10000° |

|

|

Angle repeatable accuracy |

1/10000° |

|

|

2θ Angular linearity |

International standard sample(Si, Al203), the angle of all peak in full spectrum are not more than ±0.02° |

|

|

Detector |

Proportional counters(PC) or scintillation counter(SC), Silicon drift detector(SDD), High speed one-dimensional semiconductor array detector |

|

|

Maximal countingrate of linearity |

5×105 CPS(PC、SC with the compensate function of miss counting)、15×104 CPS (SDD)、 9×107 CPS(one-dimensional array) |

|

|

Energy resolution ratio |

≤25% (PC、one-dimensional array)、≤50%(SC)、≤200eV(SDD) |

|

|

Counting fashion |

differential coefficient or integral, PHA automatically, dead time regulate |

|

|

Stability of system measure |

≤0.01% |

|

|

Scattered rays dose |

≤1μSv/h(without X-ray protective device) |

|

|

Instrument integrative stability |

≤0.1% |

≤0.5% |

|

Dimension |

1000 × 800 × 1600mm |

|