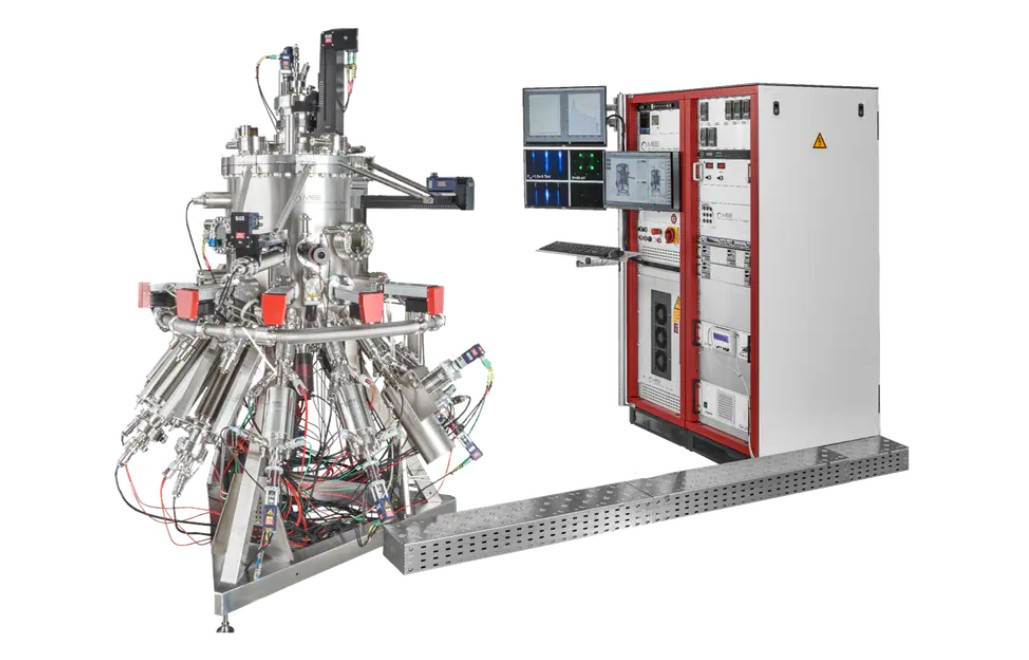

The OCTOPLUS-O 600 MBE system features flexible differential pumping options that allows depositing oxide layers under high partial pressure from a wide range of sources.

Oxide MBE System with efficient differential pumping

- Applications for many oxide and metal materials

- 12 MBE source ports DN63CF/DN100CF

- Wide range of source options; compatible to multi-pocket e-beam evaporation

- wafer size up to 4"

- customized solutions possible for dedicated processes such as Template Oxides (STO/BTO) for Silicon Integration on wafers up to 300mm

- differential pumping options, either by individual pump on each cell or by a shared pumping manifold

- Ozone-resistant SiC substrate heater or CO2 laser substrate heating

- Ozone injection close to substrate

- In-situ characterization capability

- Professional support by PhD MBE experts

General Information

The OCTOPLUS-O 600 is very thoroughly designed for oxide layer deposition. The unique design with effective differential pumping allows depositing oxide layers in high Oxygen or Ozone partial pressure without strong degeneration of the hot sources.

The OCTOPLUS-O 600 system can be easily adapted to small wafer segments as well as to 4 inch wafers.

The field-proven vertical chamber design of the OCTOPLUS-O 600 plus various state-of-the-art components allow layer by layer precise MBE growth.

Outstanding features of the OCTOPLUS-O 600 are the special design, high reliability and versatility of the system and its compactness. These features make our systems particularly suited for applications in research and development. Nonetheless specific production processes are also covered.

The standard version of the OCTOPLUS-O 600 comprises 12 source ports. A rapid pump-down load lock chamber with a horizontal working transfer rod system allows easy substrate introduction without breaking the vacuum of the MBE chamber.

We provide different kinds of effusion cells, valved cracker sources, gas sources and substrate manipulators according to customers' requirements.

Al2O3 substrate heated by CO2 laser. (Courtesy of Prof. J. Mannhart, MPI-FKF Stuttgart)

CO2 laser heating allows substrate heating up to more than 1400°C.

A backside metal coating of the substrate is not needed, since the CO2 laser light is strongly absorbed by various oxide substrates.

Please see corresponding paper.

We are happy to discuss your MBE system specifications and give competent advice for your application. Do not hesitate to contact us.

The OCTOPLUS-O 600 is in use in leading laboratories. On demand we transmit a detailed list of references.

Zone 1 (blue coloring):

-

Oxide deposition area

-

High O2 and O3 partial pressure

-

Ozone injector ring close to substrate

-

Short distance of Ozone injector to substrate

-

Low Ozone consumption

-

Ozone resistant SiC heater

-

Strong differential turbo pumping

Zone 2 (yellow coloring):

-

Source area

-

Low pressure due to small opening towards zone 1

-

Separate strong turbo pump

-

Pressure significantly lower than in zone 1

-

Shutters with low flux transient

-

Low efficient individual differential pumping of each source not needed

-

Integration of multi-pocket e-beam evaporator possible

Technical data

|

Base pressure |

< 5x10-11 mbar (depends on pumping system) |

|

Pumping |

cryopump, turbopump, TSP or ion getter pump |

|

Cooling Shroud |

LN2 or other cooling liquid on request |

|

Substrate heater temperature |

up to 800°C, 1000°C or 1400°C |

|

Substate size |

up to 2" di4meter |

|

Bakeout temperature |

up to 200°C |

|

Source ports |

12 source ports DN63CF/DN100CF. Port configuration is adapted to your source options. |

|

Source types |

effusion cells, e-beam evaporators, sublimation sources, valved cracker sources, gas sources |

|

Shutters |

soft-acting linear or rotary shutters |

|

In-situ monitoring |

ion gauge, QCM, pyrometer, RHEED, QMA |

|

Sample transfer |

linear transfer rod, manual or semi-automatic |

|

Load lock |

turbo-pumped, magazine with 6 substrates |

|

MBE control software |

Tusker |

|

Service |

system installation and acceptance testing |

|

MBE training |

by MBE experts |

Examples for applications and corresponding sources

|

Hybrid MBE Sources |

Oxygen Sources |

||||

|

Perovskite Oxides |

Sr, Ba, Ca, Al |

C |

TTIP |

O-plasma |

Ti, La |

|

High-Tc Cuprates |

Ba,Cu,Sr,Y,Pr ... |

|

|

Ozone, O-plasma |

La,Y,Pr, ... |

|

Ferroelectric Oxides |

Pb, Fe, Bi, Ba, ... |

|

TTIP |

Ozone, O-plasma |

Ti ... |

|

Magnetic Oxides |

Sr, Gd, Cr, La, Fe ... |

|

TTIP |

Ozone, O-plasma |

La, Ti ... |

|

Ultra-wide band gap oxide |

Ga, Al, Zn, In, Sn, Ge |

Si |

|

Ozone, O-plasma, O+N-plasma |

La ... |

|

Transition Metal Oxides |

Fe, Ni, Mn, Bi, Eu, ... |

C |

|

Ozone, O-plasma |

Ir, La, Ni, Ru, Mo, Ta, W, Nb, ... |