IMO FTPC PART 5, ISO 5658

The Spread of Flame Apparatus measures the flame spread of materials in marine and railway applications.

The IMO marine specification includes a collection hood for heat release measurement.

The Apparatus is constructed in accordance with the requirements of the Standard and consists essentially of two main items, the Radiant Panel Framework and the Specimen Support Framework, and a number of supplementary items.

Specification & Features

Radiant Panel Framework

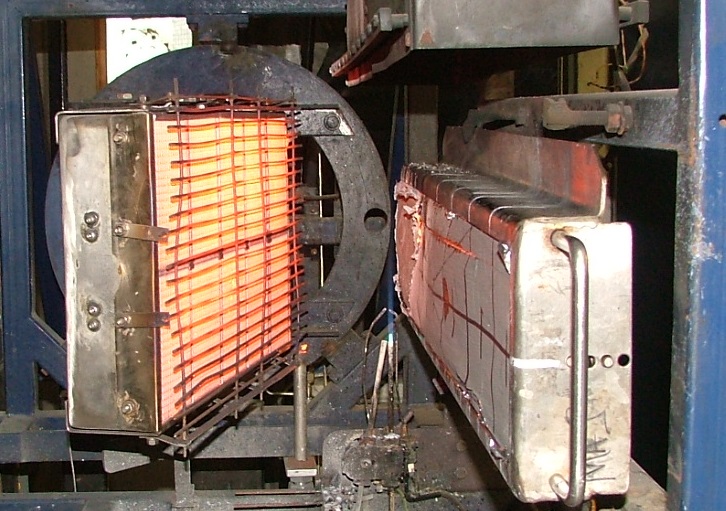

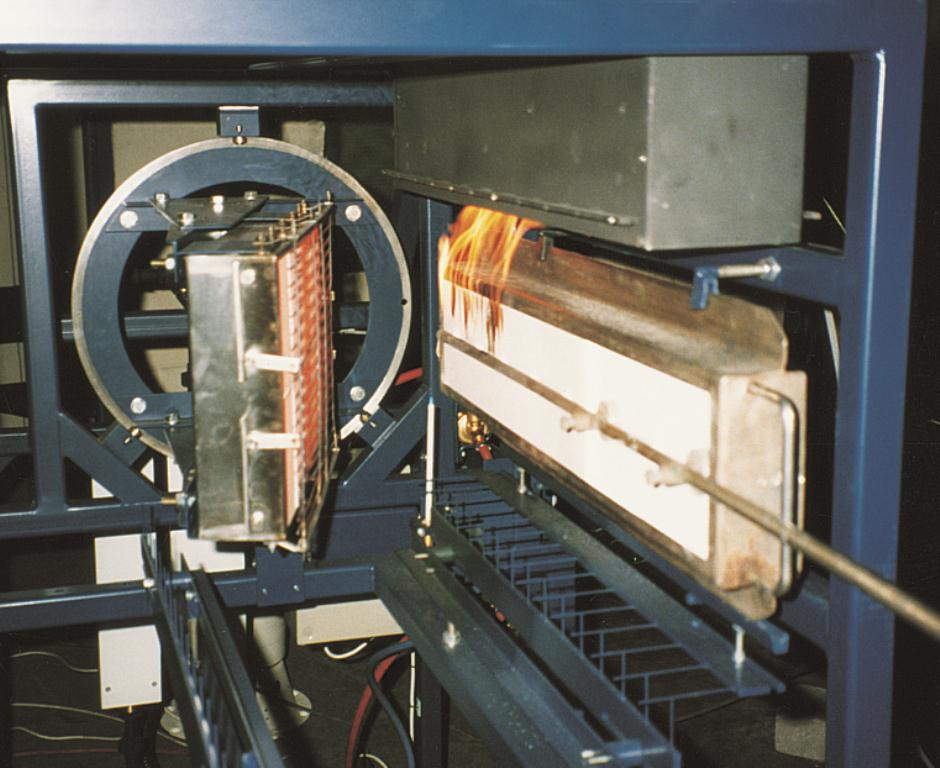

The support framework for the radiant panel is manufactured from all welded square tubular mild steel members, and includes all the associated pipework and control valves for the radiant panel. The radiant panel, which has overall dimensions of approximately 480 mm by 280 mm and consists of porous refractory tiles mounted in a stainless steel housing, is mounted on the support framework on a rotating steel ring, allowing for the testing of specimens in different orientations.

The radiant panel is designed for use with natural gas or propane gas and the gas is mixed with air prior to entry to the panel. Pressure governors and control and shut off valves are provided for both the gas and the air. Variable area flowmeters are incorporated in the supply pipework to allow the gas and air supplies to the radiant panel to be controlled and monitored.

A small control box is fixed to the framework which contains indicator lamps and push buttons associated with the gas safety system.

Specimen Support Framework

The framework which supports the test specimen is also made from all welded square tubular mild steel sections. One side of the framework contains steel guides which carry the specimen holder. Facility is available for location of a test specimen in the horizontal face upwards orientation.

When in the test position, the surface of the specimen at the end adjacent to the radiant panel is brought close to a test flame issuing from a stainless steel tube fixed to the support frame and supplied with a gas/air mixture from the main gas supplies on the radiant panel support framework.

For the IMO Specification a heat release stack is mounted on the specimen support framework and directly above the test specimen, such that the combustion products rising from a vertically mounted specimen are channelled into the stack.

The specimen support framework is linked to the support frame for the radiant panel by spacers and fixing bolts.

Specimen Holder

The stainless steel specimen holders are manufactured in accordance with the requirements of the Specification. A spring loaded quick action clamp for easy loading and retention of the test specimen is also provided.

Calibration System

This consists of a calibration board and a heat flux meter. The calibration board is manufactured from a calcium silicate based board material and is provided with a series of holes which, when the calibration board is inserted into the test apparatus, positions the heat flux meter at prescribed calibration locations.

The heat flux meter is a water-cooled-foil heat-flux meter with a range of 0 – 5 W/cm², and comes with a calibration certificate. The output from the meter is in mV and can be monitored on a suitable recording device (not supplied) or from the optional Data acquisition and software system.

Thermocouple Conditioning Device

This consists of a specially manufactured device which enables the outputs from the thermocouples on the heat release stack to be conditioned as required by the Specification.

Technical Data & Requirements

- Electrical: 230 Volts AC 50 Hz or 115 Volts AC 60 Hz

- Gas : The radiant panel of the apparatus can burn propane or natural gas. Typical gas supply requirements are a flow of up to 0.8 litres/second at a supply pressure of 200 mm water gauge.

- Air : An air supply of up to 10 litres/second and at a supply pressure of approximately 300 mm water gauge is required

- Dimensions: The radiant panel has overall dimensions of approximately 480 mm

- by 280 mm