측정 신뢰성과 낮은 비용의 Sundy SDIS401 적외선 유황 분석기는 발전소, 제지 공장, 야금, 석유 화학, 철강 공장, 탄광 등의 분야에서 석탄, 코크스, 재, 바이오 매스 연료 및 기타 가연성 물질의 황 함량을 측정하는 데 사용할 수 있습니다.

Highlights

High precision.

- Unique designed high temperature combustion tube with secondary combustion function, make sure the samples combust thoroughly.

- Adopted high sensitivity and low drift infrared cell,the measurement result is stable and reliable.

- Top quality ultra low drift infrared cell to ensure stability, precision and accuracy.

- Unique gas tightness.

Intelligent control.

- Easy-to-use Windows-based software, It only needs to click the mouse after weighing and placing the samples.

- Easy data handling, real time data can be transmitted by internal network.

- With Ethernet bus communication technology, one PC controls several analyzers.

- Capable of connecting with network and balance by RS232 interface.

SDIS401 infrared sulfur analyzer is an instrument scheduled to analyze the sulfur content in coal or other substances by infrared spectroscopy.

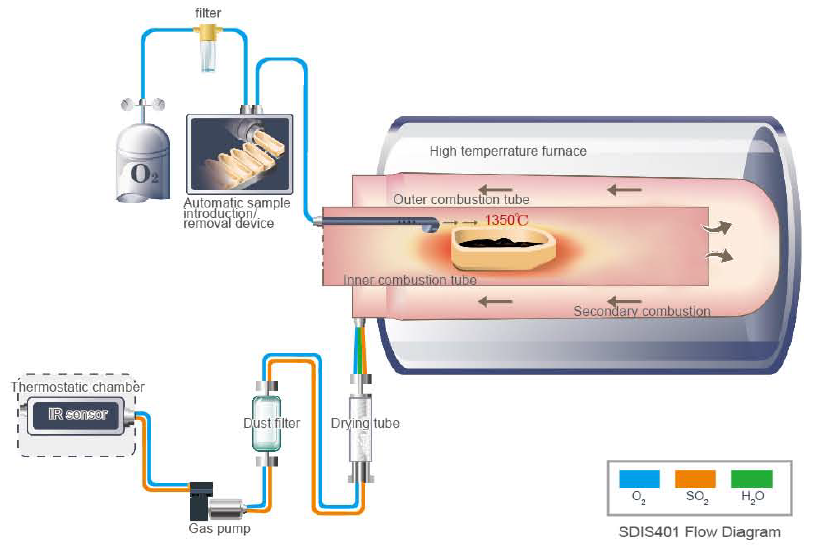

For a complete analysis made by SDIS401 infrared sulfur analyzer to a sample, three steps: gas circuit cleaning, combustion and analysis shall be experienced. First, place the sample on the sample place platform , input the interrelated parameters, and click the "start test", then push the sample into the furnace according to the system prompt. The system will automatically analyze the sulfur element content in the sample according to the specified procedures and show the test results on the main interface window of the software.

In the combustion process, the sample is delivered into the combustion furnace for peroxide combustion, and the gases generated therefrom shall be conveyed into combustion tube for secondary combustion, after multi-stage filtration and drying, the gases go into the infrared cell for real-time analysis in the form of SO2 by the infrared sensor.

The final analysis results are shown on the main interface window of the software in the form of percentage by the samples quality.

Specifications

|

Description

|

SDIS401

|

|---|---|

|

Test Method

|

Infrared Absorption

|

|

Sulfur Determination Range

|

0.01% - 50% (can be extended to 100%)

|

|

Standards

|

AS 1038.6.3.3, ASTM D1552, ASTM D3177, ASTM D4239, ASTM D5016,ISO 19579, BS 1016

|

|

Sulfur Resolution

|

0.001%

|

|

Analysis Time/sample

|

< 2 min

|

|

Preheating Time

|

≤ 120min

|

|

Sample Loading

|

1

|

|

Sample Weight

|

80 – 500 mg (100 mg Recommended)

|

|

Furnace Temp

|

1250 ℃ - 1350 ℃

|

|

Heating Elements

|

Silicon Carbide

|

|

Temp. Control Precision

|

±1 ℃

|

|

Temperature Sensor

|

Thermocouple

|

|

Power Requirement

|

220V (-15% ~ 10%), 50/60Hz

|

|

Max. Power

|

4 kW

|

|

Gas Requirement

|

99.5% purity oxygen ≥1MPa

|

|

Gas pressure

|

Oxygen: 0.28 ±0.01 MPa

Total Air Flow ≥ 1MPa

|

|

Sample Introduction and Discarding

|

Manual

|

|

Gas Flow Checking

|

Rotor flow meter adopted gas flow by visual check

|

|

Chemical Reagents

|

Dehydrite

|

|

Humidity

|

≤ 85%

|

|

Ambient Temperature

|

15 ~ 30 ℃

|

|

Operational Control

|

Windows®-based software on external PC

|

|

Operation Cost

|

Oxygen consumption lowered by intelligent gas supplying system.Desiccant: Dehydrite which is of higher cost

|

|

Advance Calculation

|

Yes

|

|

Analysis Report

|

Yes

|

|

Statistics Report

|

Yes

|

|

System Monitor

|

Yes

|

Sundy SDIS401 Infrared Sulfur Analyzer can be used to determine the sulfur content in coal, coke, ash, biomass fuels and other combustibles in fields of power plants, coal mines, paper plants, metallurgy, petrochemical, steel factory etc.

Test reliable, cost-effective.