SDAC6000u는 건축 자재뿐만 아니라 석탄, 코크스, 원유, 오일, 시멘트 흑분, 바이오 매스 연료와 같은 고체 및 액체 가연성 물질, 다양한 식품의 발열량을 결정하는 데 사용될 수 있습니다.

Fully automatic bomb raising & lowering, full test process is less than 10 minutes

Optional support stand, customer can choose either benchtop or vertical type

Features:

발열량 측정과 구동에 최적화된 디자인, 완전 자동화된 oxygen bomb 탈착, 모든 테스트 프로세스는 10 분 미만에 완료됩니다.

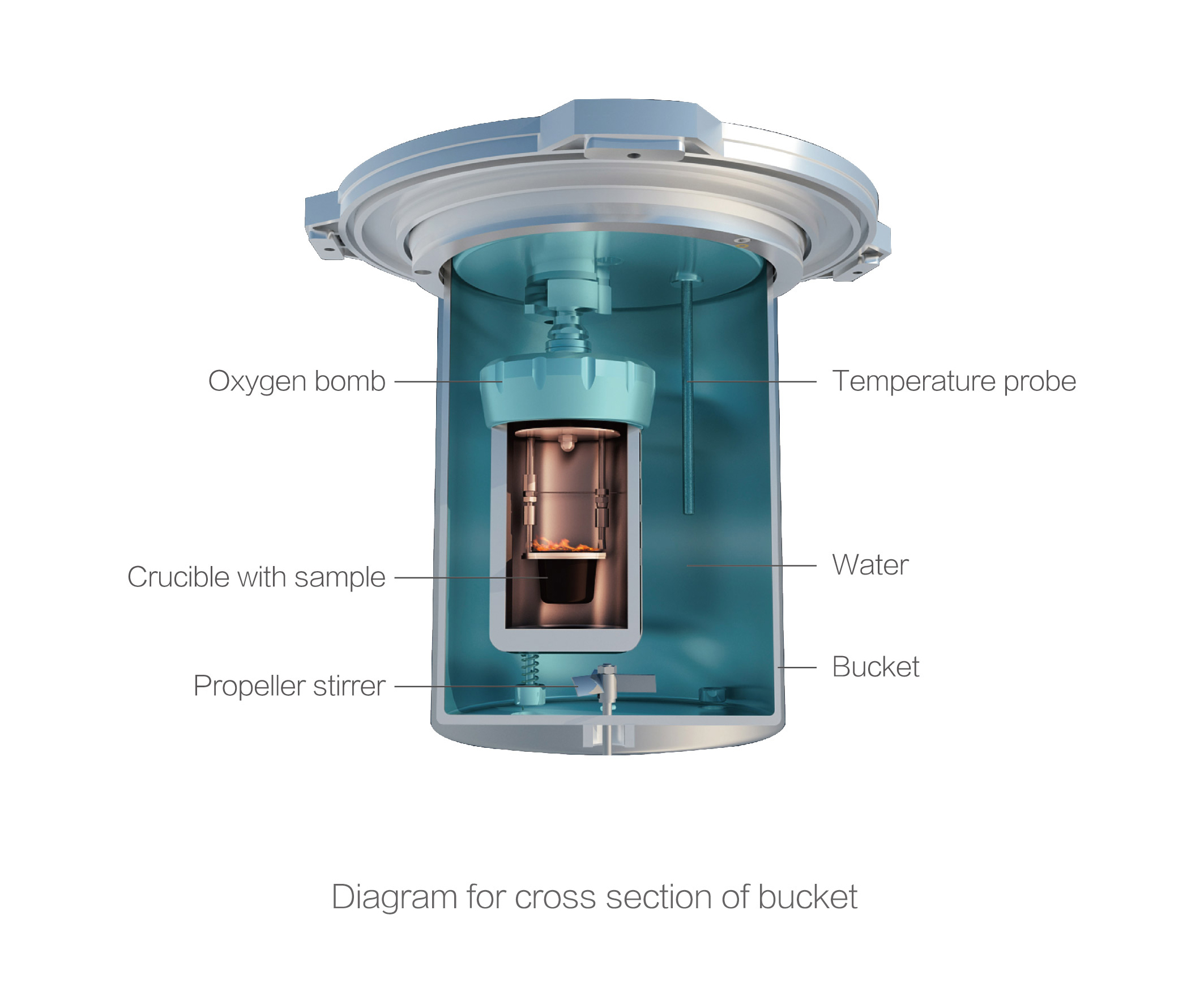

- Unique bucket water circle system, which can determine water volume for each testing automatically. New stainless steel oxygen bomb can be easily assembled and disassembled. High stirring efficiency by propeller, faster heat transfer of oxygen bomb, testing time is greatly reduced.

- Built-in intelligent water tank with heating and cooling function, water temperature can keep constant, non-stop working available.

- High automation: bomb raising & lowering, determination of bucket water volume and control of water , temperature and test can be finished automatically.

Good environment adaptability, precise, accurate and reliable rest result.

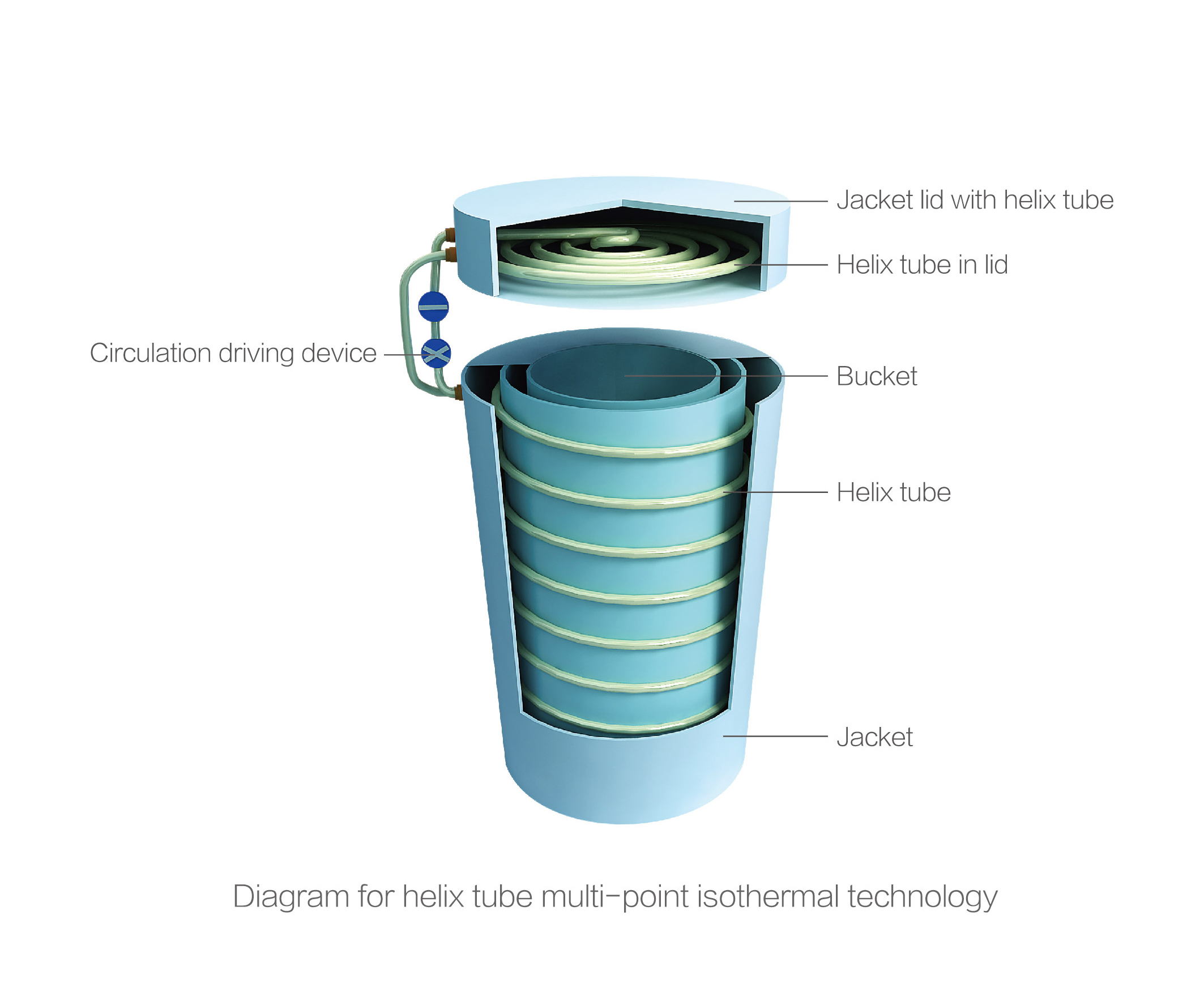

- Helix tube multipoint isothermal technology, create a controllable and stable internal environment (consists of jacket and jacket lid, temperature difference ≤0.1℃), stop the interference of external environment (such as air flow, temperature) to bucket, test result is eliable.

- Independent jacket and bucket water system. After the test, bucket water automatically flow back into water tank, no affection between inlet and outlet of bucket water and jacket water. Jacket water temperature is stabilized.

Accurate and reliable test result

- Larger heat capacity make the testing result is more accurate and reliable.

- Reasonable structure, reliable operation, safe and environment friendly

- With self-diagnostic function, malfunction can be detected accurately, easy to maintain.

- Unique crucible support design, convenient to use.

|

|

|

Specifications

|

Description |

SDAC6000u |

|---|---|

|

Analysis Time |

Analysis Time: ≤ 8 minutes, Full Test Process: ≤10 mininutes |

|

Temperature Resolution |

0.0001 ℃ |

|

Precision (RSD) (1g Benzoic acid) |

≤0.05% |

|

Heat Capacity Stability |

≤0.2% within three months |

|

System Structure |

Benchtop / Vertical |

|

Conformance with Standard |

ASTM D5865, ASTM D240, ASTM D4809, ASTM E711, AS 1038.5,BS EN 15400, BIS1350,ISO 1928, ISO 9831, ISO18125 |

|

Test per Hour |

6 times |

|

Bomb volume |

250ml |

|

Calorimeter Type |

Isoperibol |

|

Oxygen Filling |

Semi-automatic / automatic |

|

Bomb Washing |

Manual |

|

Max.Bomb pressure |

20Mp |

|

Bomb Identity |

Yes |

|

Gas Requirement |

99.5% Oxygen |

|

Water Requirement |

Distilled water |

|

Energy Measurement Range |

0~50000J |

|

Bucket Filling |

Automatic |

|

Constant Volumetric Tank with Temp Control Device |

Bucket determine water volume automatically |

|

Independent Bucket and Jacket Water System |

Yes |

|

Stirring Method |

Propeller |

|

Power Inverter |

No |

|

Reproducibility based on analysis of 1g Benzoic Acid |

0.10% |

|

Average Temperature Increase |

2℃ |

|

Temperature Measurement |

PT1000 |

|

Working Temperatures |

≤32℃ |

|

Cooling Method |

Refrigerating Device |

|

Network |

Yes |

|

Power |

220V(-10% +10%), 50/60Hz |

|

Max.Power |

0.6KW |

|

Dimension |

Main body: 440 x 550 x 460 Water tank: 390 x 550 x 440 |

|

Weight |

50kg |

|

Advance Calculation |

Yes |

|

Analysis Report |

Yes |

|

Statistics Report |

Yes |

|

System Monitor |

Yes |