Accurate and versatile

The core of the Q-Vis viscometer is an oscillating quartz which is robust and versatile: with its wear-free crystal, Q-Vis can determine the dynamic viscosity of both stagnant and flowing liquids. Being fully independent of the flow conditions, you can test with reliable accuracy even under turbulences.

And here is how Q-Vis works: Once immersed into the test liquid the oscillating behavior of the quartz changes. Each influence on the oscillation has specific characteristics and will be analyzed by the device to determine the viscosity. This patented, tried and trusted measuring method makes our Q-Vis a unique instrument that opens up many new possibilities for the determination and for the control of viscosity.

Key features

- Suitable for both in-line and laboratory measurement

- Determination of the dynamic viscosity as a function of the temperature

- Simultaneous display of the kinematic viscosity

- Torsional transducer measurement, independent of type or direction of flow

- High shear-rates without adverse effects on the tested fluid

- Large measuring range (1 to 10.000 mPa*s)

- Only small samples required for lab measurements (approx. 35 ml)

- Short set-up and measuring times

- Easy to handle and to clean

- Robust quartz sensor without any moving parts

- Standard RS-232 digital interface for optional connection to your Windows PC

Fields of application

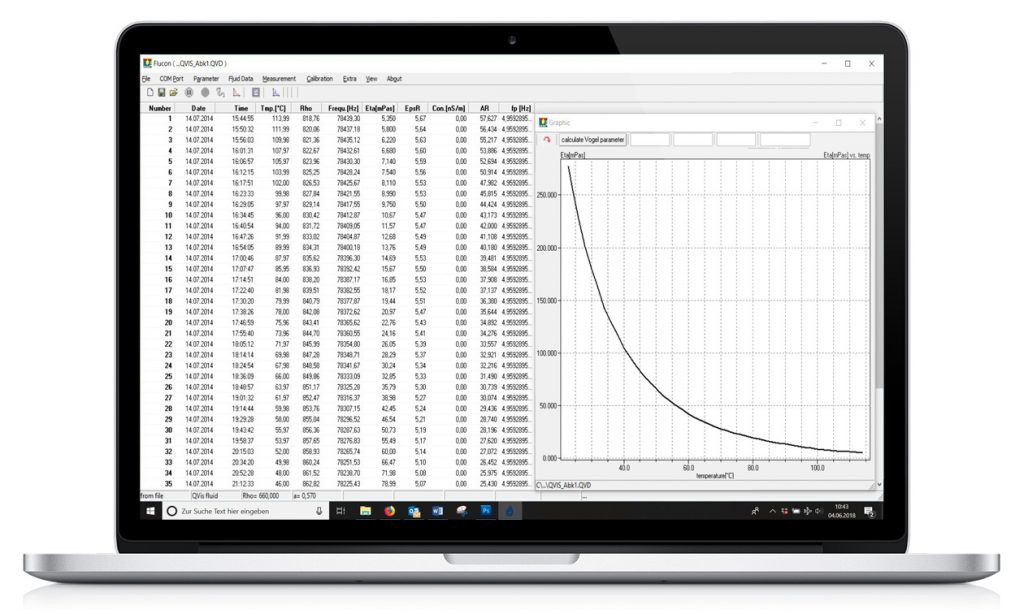

The Q-Vis Viscometer can be operated either in stand-alone mode or - with the included powerful software - on any Windows PC via RS-232 or USB. Its additional analog output can also be used to surveil your process and even actuate certain control elements, e.g. for diluent admixing.

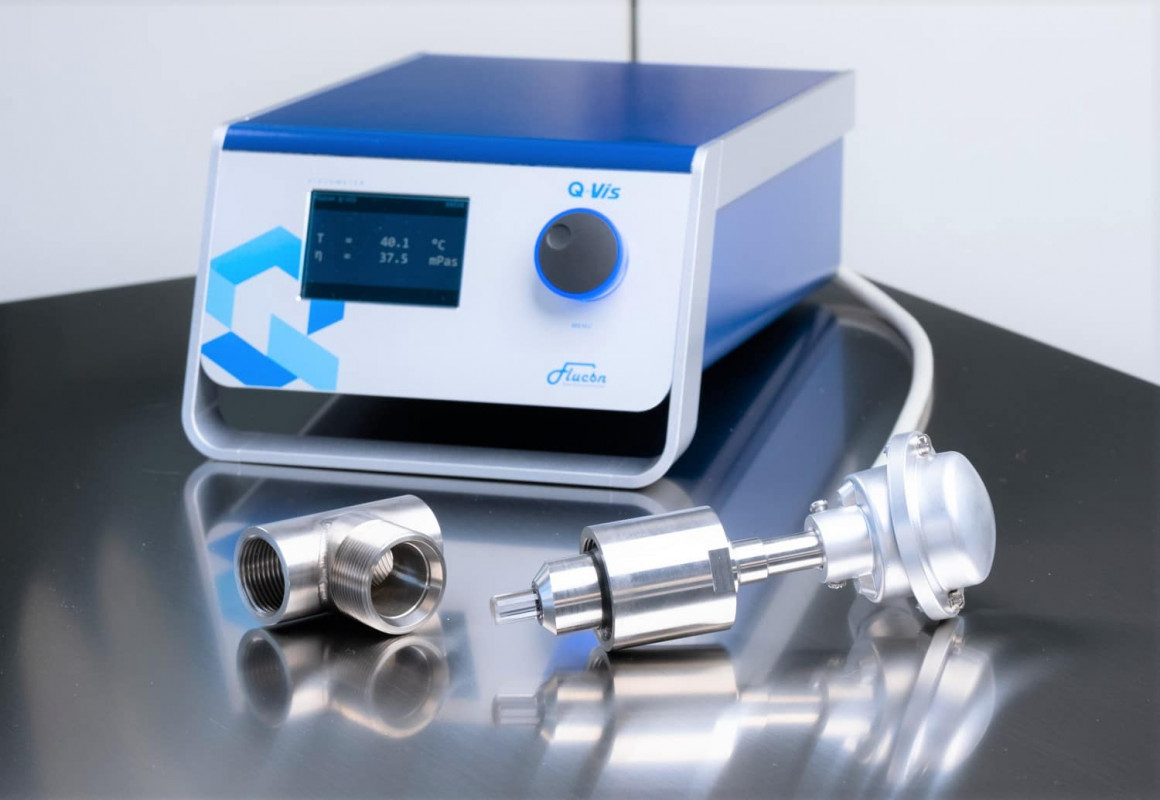

Q-Vis versions

Q-Vis is available in two different versions:

- as our standard online viscometer and

- as a compact version .

Furthermore, for application in explosion-hazardous areas, Q-Vis is available as an explosive-proof process viscometer. All Q-Vis types are characterized by their high measuring accuracy, easy handling and a maximum of operational safety.

When used in the lab Q-Vis creates additional possibilities for fluid development.

In test facilities it enables a quick and reliable quality control, Q-Vis will help you improve your process control and quality assurance.

Viscosity

Definition Viscosity

Viscosity describes a property of fluids: a high viscosity signifies a tendency towards a state of thickness or solidness and a low viscosity is attributed to fluids that are thin and flow easily.

The term “viscosity” goes back to the word “viscum” which is latin for mistle. The berries of this plant yield a very sticky and gooey juice which was spread on branches in order to catch birds.

Viscosity is expressed in terms of Pas or mPas.

Typical viscosity values

| Fluid | Viscosity in mPas |

|---|---|

| water (20°C) | 1,00 |

| grape juice | 2 bis 5 |

| olive oil | ≈100 |

| honey | ≈10.000 |

| asphalt | ≈1011 bis 1016 |

| lacquer | ≈100 |

| motor oil (25°C) | ≈100 |

| motor oil (150°C) | ≈6 |

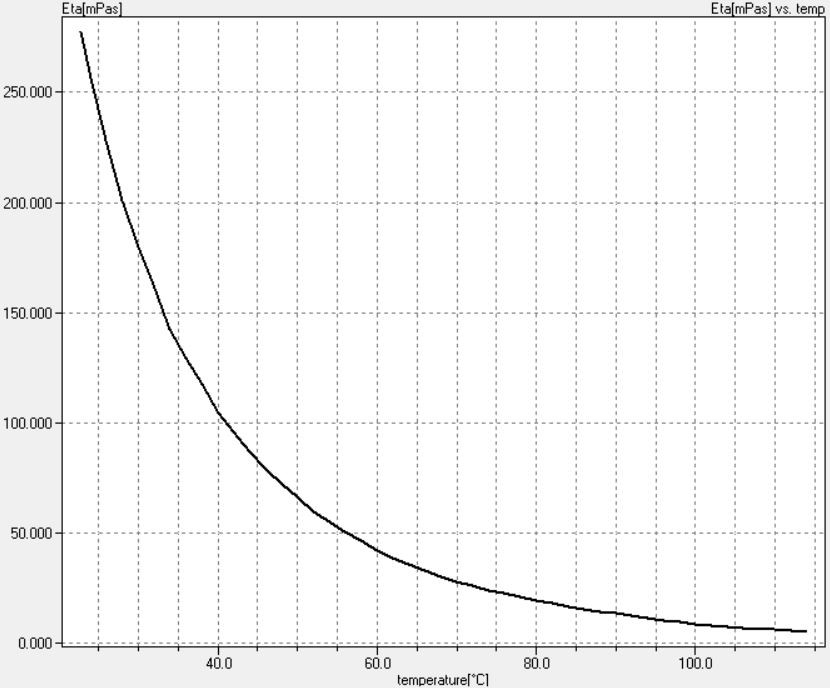

Viscosity in relation to temperature and pressure

The discrepancy in the viscosity given above for motor oil at different temperatures (25°C and 150°C) is an indication of the fact that the viscosity of a fluid is temperature-related. For most fluids, the rule applies that with an increase of temperature there is a decrease of viscosity. Furthermore, viscosity is also pressure-related. When pressure is increased, viscosity increases as well.

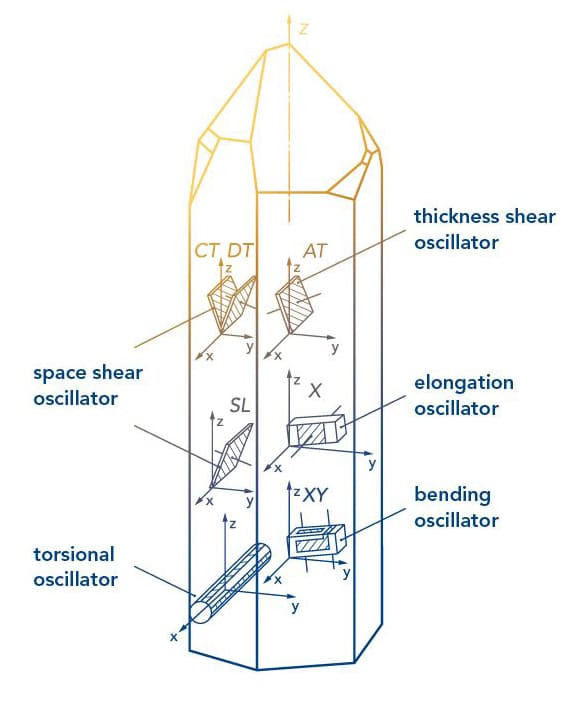

Fundamentals of quartz viscosimetry

Starting point

The principle of quartz viscosimetry is based on the idea of W.P. Mason. The basic concept is the application of a piezoelectric crystal in the shape of a torsional oscillator for the determination of viscosity. On the one hand, the high-frequent electrical field that is applied to the oscillator causes a movement of the sensor and in consequence the shearing of the fluid. On the other hand, the movement of the sensor is influenced by the external forces (the shear stress) of the fluid which affects the electrical response of the sensor.

Development of the quartz viscosimeter QVis

The calibration procedure as a prerequisite of viscosity determination using a quartz goes back to the founder and CEO of flucon fluid control GmbH B. Bode who facilitated the detailed analysis of the electrical and mechanical transmission behavior of the oscillating system. On the basis of this calibration, the quartz viscosimeter was developed which allows continuous viscosity determination in resting and flowing liquids.

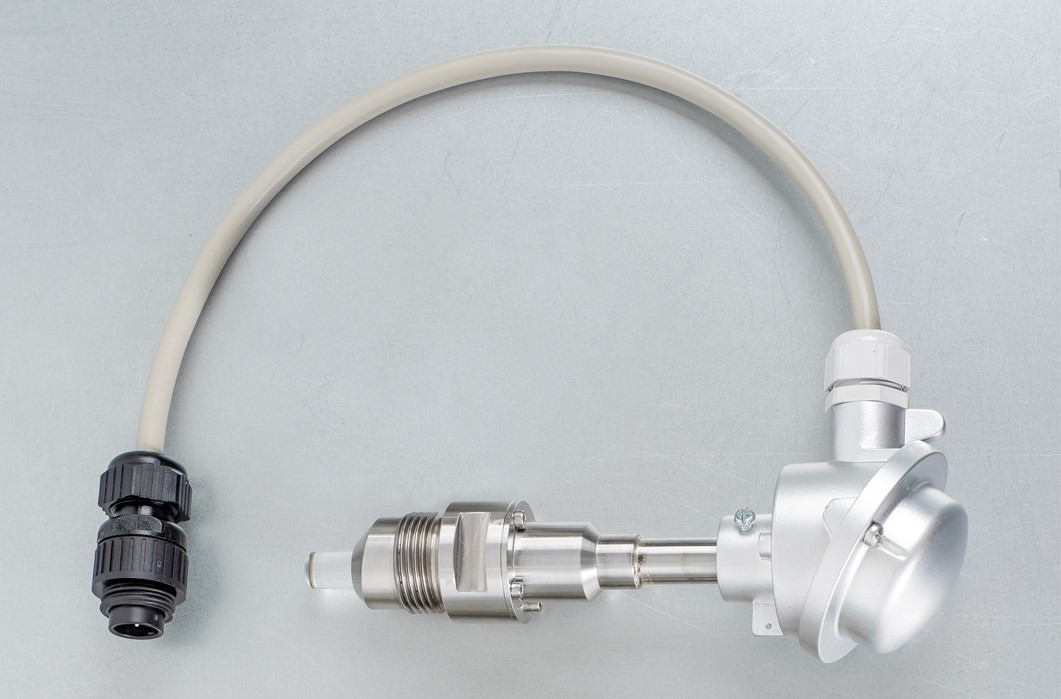

The QVis is comprised of two components, the electronic unit equipped with an electronic control and evaluation system on the one hand, and the measuring head which surrounds the quartz on the other hand. The micro processor which is part of the electronic unit is responsible for determining the oscillating behaviour of the quartz crystall sensor. With the help of the calibration function, the viscosity is determined in a next step.

Advantages of viscosity measurements by means of a quartz sensor

- no molecular destruction of the measuring fluid

- no temperature effects on the measuring fluid

- small sample sizes sufficient

- large measuring range (1 to 10.000 mPas)

- chemical resistance of the quartz sensor

- suited for temperatures up to 500°C and pressure up to 10 kbar

- resistant against dirt and deposits

- easy to clean

The Q-Vis sensor

The quartz used for viscosity measurements is cut out of a synthetically produced single-crystal. This type of crystal is applicable for high temperatures (up to ~500°C) and high pressure (up to 10 kbar) viscosity determinations and is furthermore characterized by its high chemical resistance. The quartz crystal used for the Q-Vis sensor is a so called torsional oscillator. A torsional oscillation is generated when an object is twisted/distorted; with the Q-Vis, the creation of an electrical field causes such torsional oscillations. It should be noted that only torsional oscillation can create perfect shear stress within the liquid which is an essential precondition for an accurate determination of viscosity. The oscillating of the sensor causes a high-frequent shearing (approx. 56 kHz) of the measuring fluid. At the same time, the energy input into the measurement substance is comparibly low (significantly smaller than 100 mW).