What would the world be without colors?

The quality of color is equally important for printing, and the production and application of paints, varnishes, coatings, etc. However, color is not just color and in each case the viscosity of the materials involved plays a central role for a perfect result.

Our QVis quartz viscosimeter is your reliable tool for the continuous visco-monitoring of paints, lacquers & coatings.

Viscosity is key.

Depending on the field of application, paints, lacquers and coatings show a wide variety of compositions. Nevertheless for all of them their consistency, i.e. their fluidity or viscosity, is of decisive importance. If the product used is too thick (highly viscuos) or too thin (lowly viscuos) for the respective machine, the liquid cannot be handled optimally in either case.

Also, the ideal mixing ratio must be monitored continuously in order to counteract evaporation effects in the process and to keep the viscosity on a constant level. The QVis quartz viscosimeter has been expertly designed to deal with these challenges in a masterful way.

Monitoring your paints, varnishes and coatings.

당사의 Quartz viscometer QVis의 핵심은 고주파의 진동을 받는 quartz crystal 입니다. Quartz sensor를 감싸고 있는 유체의 진동 (oscillation) 영향으로부터 결정됩니다. 페인트, 바니시 및 코팅 산업에서 이미 널리 사용되는 이 혁신적인 메카니즘을 통해 공정에서 지속적이고 실시간으로 동적 점도 (dynamic viscosity)를 측정 할 수 있습니다.

Maximum flexibility for your installation.

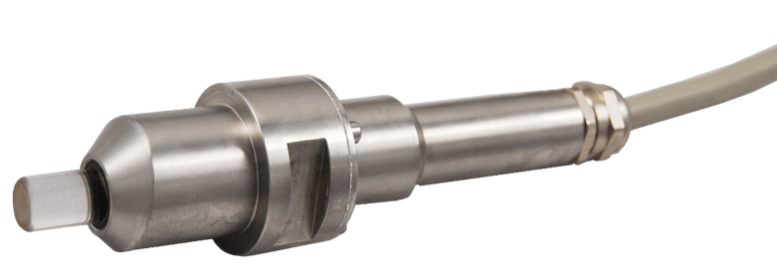

Since the viscosity measurement with QVis is independent of the direction of flow, and since it can be used for a large measuring range without requiring a change of the probe, the sensor can be installed at any desired location, e.g. directly into your pipe or tank.

Since the viscosity measurement with QVis is independent of the direction of flow, and since it can be used for a large measuring range without requiring a change of the probe, the sensor can be installed at any desired location, e.g. directly into your pipe or tank.

The quartz crystal of the QVis sensor is extremely robust and enables the continuous measurement of the viscosity even under harsh process conditions, with no moving wear parts involved.

Compact and cost-effective viscometer: optimized for installation in plants

Key features at a glance:

- Compact and economical viscometer for standard installation

- Robust, wear-free quartz sensor

- Analog interface (4...20 mA or 0...10 V) for the measured data

- Inline measurement of dynamic viscosity and temperature

- Optional output of kinematic viscosity

- Viscosity measurement independent of the type of flow

- Large measuring range (1 to 10.000 mPas) without a change of the measuring head

- Easy to handle, easy to clean

- Standard interface (RS-232) for optional connection to a control computer

- Optional connection to an operator terminal with LCD

Technical Specifications:

| Voltage supply | 110-240 VAC or 9-36 VDC |

| Viscosity range | 1 to 10.000 mPas |

| Accuracy | ±2% deviation for reference calibration |

| Measuring time | approx. 15 s |

| Measuring frequency | Approx. 56 kHz |

| Temperature range sensor | -20°C to 120°C (optionally up to 300°C) |

| Pressure range sensor | max. 25 bar |

| Temperature measurement | PT100 (4-wire technology), ±0,1°C |

| Dimensions electronic box (LxWxH) | 200 x 112 x 70 mm |

| Dimensions sensor | L=50mm immersion depth, also available in version with G1"thread |

The patented and well-proven measuring principle makes our QVis system unique and opens up new possibilities in the area of viscosity determination and regulation. The high-shear gradient allows measurements in the high-shear range, without undesirable temperature regression or any other influence on the test substance.

The QVis generates analog output values (4...20 mA or 0...10 V) for further processing. If desired, the PC program included in the scope of delivery can be used to connect the QVis to your WINDOWS computer to record the measured values.