AJA International사의 ATC-B Series Batch Coating System은 여러 개의 기판을 소규모로 생산 가능하도록 제작되는 맞춤형 스퍼터링 증착 시스템 (sputtering and evaporation system) 입니다. 특정 요구 사항에 따라 실린더형 또는 박스형 챔버가 사용됩니다. 처리 시간이 길어지는 경우, 재료가 기판 또는 마그네트론 스퍼터 소스로 떨어지지 않아 단락으로 인한 공정 중단이 없어 수평한 마그네트론 스퍼터링이 일반적으로 가장 많이 쓰입니다.

To optimize these systems for a given PVD process, AJA engineers can draw on a long history of standard and custom sputter source and substrate holder designs to satisfy the specific needs of the application. For example, the ATC-B 3400-H horizontal cylinder has special magnetron sputter sources which are designed to reliably run a 50,000 layer processes that can take up to 4 days to complete.

TYPICAL BATCH COATING SYSTEM CONFIGURATIONS

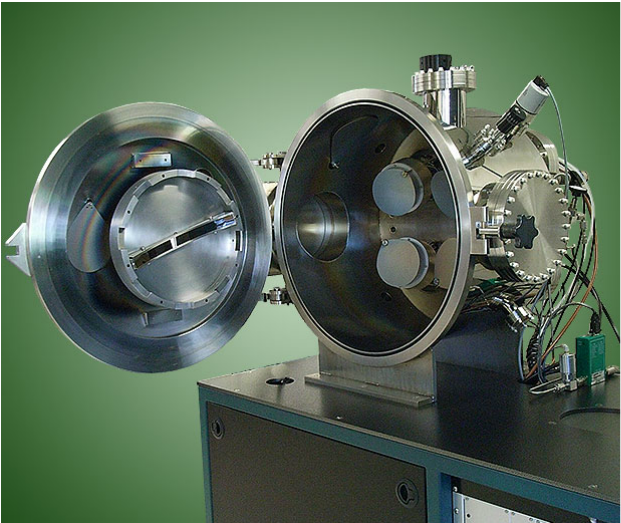

Typical Box Chamber Configurations

For coating substrates up to 300mm in diameter,

this system accommodates up to (4) 4” sputtering

sources simultaneously using (2) sources at different

angles to uniformly coat 300mm Ø area.

This tool also includes a broad beam End Hall ion source

for substrate pre-clean and sample preparation.

A box coater with multi pocket rotary e-beam source

and dual thermal sources. This model was fitted

with a (4) x 4" wafer flat planetary substrate holder.

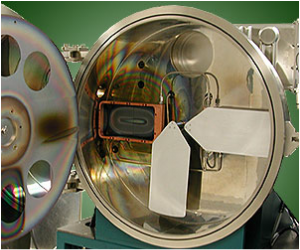

For CD mastering, this system handles one rotating

substrate at a time and employs a single AJA Nautilus

Series Rotating magnetron for optimum uniformity.

Small in-line coater designed to utilize AJA STXL

rectangular magnetrons to coat multiple substrates

on a moving pallet. The pictured system was used

to make large quantities of 1mm x 5xmm,

temperature sensitive Platinum on ceramic sensors

for use in thermostats.

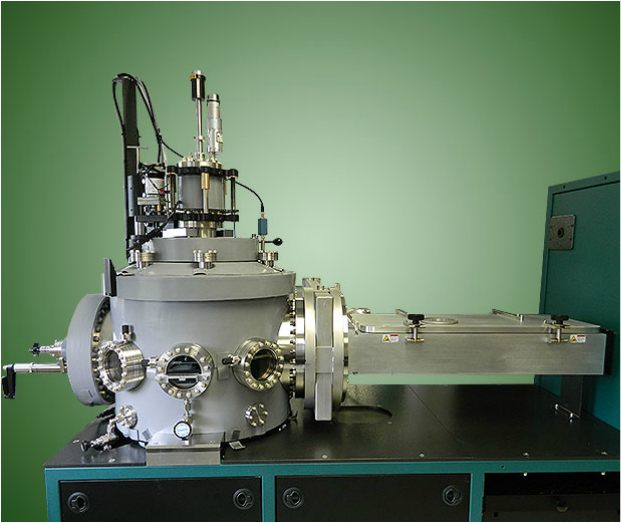

Typical Cylindrical Chamber Configurations

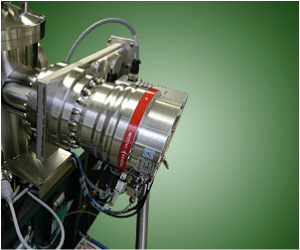

Extended process side sputtering batch coater

designed for a proprietary application requiring

40-50 thousand layers per run.

Custom AJA STXL-EO (extended operation) magnetrons

were designed to prevent aborted processing

due to source shorting. This system will process

(8) 6" substrates or hundreds of smaller substrates per batch.

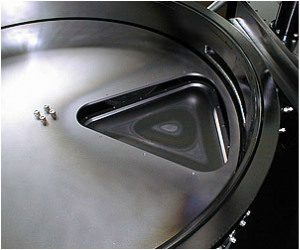

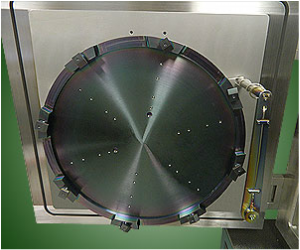

Mask making tool processes (6) 8" wafers per batch

with up to (3) materials deposited

from AJA TR5313 triangular magnetrons

for optimum uniformity. The system also includes

a 7 substrate cassette in the load-lock

to boost throughput up to (60) 8" substrates

(or thousands of small substrates) per 8 hour period.

Capable of coating concave, 25 mm thick, X-ray mirror substrates up to 300 mm in diameter with +/- 2% uniformity utilizing (4) in-situ tilt sputter guns. The substrate carrier can also be replaced by planetary tooling for a batch of 3D objects or small wafers or coupons.

The bake jacketed UHV system above is configured to coat up to (4) 4" diameter, 1" thick Ge substrates per batch from both sides by utilizing an in-situ substrate pallet flipping mechanism.

RF biasable batch substrate holder with in-situ flipping capability

with heavy duty magnetic transfer system for 6 kg substrate pallet

SPUTTERING SOURCES

AJA has designed and delivered over 100 different types of magnetron sputter sources since 1991. AJA has the capability to precisely match the sputter source to the requirement with proven technology. The STXL Series (linear, 50 mm to 150 mm wide and up to 1 meter long), the STX Series (5" to 12" diameter), the Nautilus Series Rotating Magnetrons (8", 10" and 12" diameter), the TR Series Triangular Magnetrons and the CTM Series Hollow Cathode Cylindrical Magnetrons (2" to 12" ID) are all AJA designs with proven track records which can be employed to get the job done as efficiently and as reliably as possible.

Most AJA production magnetron sputter sources feature the unique modular magnet array allowing the sources to be configured for balanced, unbalanced, magnetic material and facing target sputtering.

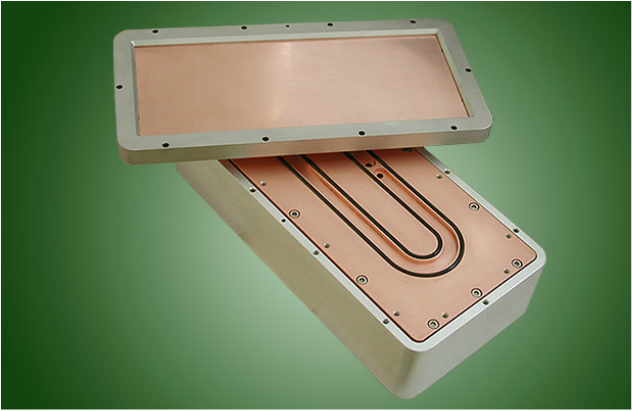

AJA's STXL Series Magnetrons feature direct-cooled copper backing plates for maximum deposition rate and easily accessible magnet arrays. This allows the end user to choose between optimum uniformity or optimum target utilization of up to 60-70%. The sources feature integral gas injection and high power RF or DC operation. Rectangular versions in 75, 100, 125 and 150 mm widths are offered up to 1 meter long. Both internal mount (via flex hose or solid tube) and external flange mount designs are available.

Cylindrical target magnetron used for 3D sputtering

where substrates are immersed into the target / cathode.

Triangular magnetrons specialty sources designed

to optimize deposition uniformity onto a circle of substrates

up to 8" Ø.

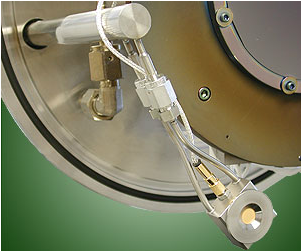

Sources feature in-situ tilting and are ideal for uniform

coatings on multi-substrate pallets up to 300 mm Ø.

Tunable magnetrons with water cooled isolation designed

to prevent aborted processing due to source shorting.

Configurable magnet array allows the user to optimize target utilization, uniformity, or even "intentional non-uniformity". This source has also been used with segmented, multi-material targets depositing onto spinning substrates to perform direct, variable co-depositions from a single magnetron as the power supply output is synchronized to change power for each segment being sputtered.

SUBSTRATE HOLDERS - HEATING / COOLING

AJA has designed over 130 different types of customized substrate holders and fixturing for custom pilot production batch coating systems since 1991.

These include rotating, indexing, linear and planetary motion, plus heating, cooling and RF/DC biasing. Different aspects of these proven designs can be combined to create a new, yet highly reliable custom substrate holder. Reliable substrate holder design is one of the most crucial parts of a custom batch coater and manufacturer experience can easily account for the difference between a maintenance intensive machine and the high throughput machine everyone desires.

Accommodates up to (9) 6" wafers, 6 (8") wafers

or a large number of smaller substrates.

This continuously rotating assembly can be configured

with RF/DC bias, backside heating and a "quick

exchange" substrate pallet.

Features (4) manually removable carriers for convenient,

bench-top substrate mounting or cleaning. The assembly

accommodates (4) 100 mm wafers or numerous smaller

substrates. Larger versions holding up to four 300 mm Ø

wafers are also available.

Accommodates up to (8) 2.0”x 1.5" substrates

capable of continuous rotation and position indexing

via stepper motor control. Also

compatible with load-lock transfer.

Accommodates up to 300 mm Ø substrates.

Mounted on hinged door for easy access

and includes positionable quartz crystal thickness

monitor.

PHASE II-J COMPUTER CONTROL

The AJA Labview based Phase II-J computer control system is used on all ATC-B Series Batch Coaters. This straightforward, user friendly control system utilizes a large, flat-screen laptop in a 19” rack drawer connected to a single 7” high x 19” wide rack mount hardware module. The back panel of the hardware module is populated with connectors to interface to all aspects of the sputtering system.

The Phase II-J control system allows the user to operate in either the “manual mode” or the “automated processing mode”. In the “automated processing mode”, the user designs process “layers” which are then compiled and saved as a “process”. The system allows 104 unique user entry points which are accessible only by password, limiting access to a user’s layers and preventing unexpected corruption of a user’s saved processes.

The standard Phase II-J control system will accommodate up to (5) DC power supplies, (4) RF power supplies, (1) 4-way DC switchbox, (1) 4-way RF switchbox, (4) process gases, closed loop automatic pressure control and substrate temperature control. Processes are aborted if plasma is not detected. Special “soak layers” can be easily incorporated into the process. Finally, data logging is standard with an adjustable refresh period. Process data can be downloaded to common spreadsheet programs.

Large screen laptop on convenient slide drawer

for Labview based ATC system computer control.

Replacement laptops are always in stock.

Compact 4U rack mount case. This module is fitted

from the outset with all receptacles for quick field retrofits/upgrades.

SYSTEM OPTIONS

Cooling/Flow Sensors and for Non- Hazardous Gases

slide drawer

380V systems

Pressure Control with alternate Position Mode

for Upstream Control

하기