Safety Management Services, Inc. (SMS™) manufactures the ABL Electrostatic Discharge (ESD) Machine for clients who require in-house testing capability to determine energetic material response to an ESD event. The ABL ESD machine is one of the industries core sensitivity test machines for producing industry standard levels of energetic material sensitivity data.

The ABL ESD Test Apparatus delivers an electric shock or spark through a small sample of test material. Reaction of the material is determined by operator observation, detection of decomposition by a gas analyzer, or utilizing the SMS developed GoDetect-ESD™ high speed video detection system. The amount of energy required to cause a material to react is used to evaluate the sensitivity of the material to an ESD event. The sensitivity data can also be used to determine critical safety parameters related to manufacturing and handling of the materials being tested.

Current practices in industry are concentrated on determining if a material can be safely handled for experimental, developmental, and production purposes. Typically, scale-up procedures for materials that are potentially sensitive to electrical shock require some form of testing to evaluate the energy required for initiation. The measured sensitivities are compared with in-process energy potential to determine if safe limits could be exceeded during processing or handling. The ABL ESD machine is capable of yielding results in engineering units for direct correlation to in-process energy.

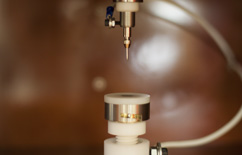

The ESD test apparatus is capable of performing both the “approaching needle” method and the “fixed gap” method of ESD tests. The most commonly used approaching needle

method is intended to simulate an event of two objects approaching one another, one with a positive and one with a negative charge, such that a discharge occurs at a finite separation distance. To accomplish this, the discharge needle is moved rapidly toward the test sample by an air-operated solenoid. As the gap between the needle and ground closes, the electrical energy is discharged through the sample.

ESD Testing of Smokeless Powder on High-Speed Video

SPECIFICATIONS

Meets criteria for: MIL-STD 1751, methods 1031, 1032, and 1033

OPERATING RANGE

• “Approaching Needle” method

• “Fixed Height Needle” method

• 0-0.75” adjustable gap between electrically charged needle and grounded base plate

• Adjustable capacitance values ranging between 0.10E-04 - 0.75 microfarad

• 0 - 10,000 VDC applied voltage range

• 120 VAC (220 V single-phase @ 50 HZ for international applications)

STANDARD HARDWARE

• Sample Holders with certified flatness, hardness, and surface finish

• Sample insulators

• ESD Needles

OPTIONAL HARDWARE

• Reaction detection system

• High speed video

• Data aquisition system including laptop

• GoDetect software (inquire for more details)

SAFETY FEATURES

• Safety interlocks on all access doors to prevent access to internal componenets when the machine is electrically charged

• Remote firing switch to be used when testing highly sensitive materials

• Operator shielding