ISO 5660, BS476 PART 15, ASTM E 1354, ASTM E 1354, ASTM E 1550, ASTM E 1740, ASTM D 5485, ASTM D 6113, NFPA 271, NFPA 264, CAN ULC 135

- High Accuracy Weigh Cell with 0.05g resolution

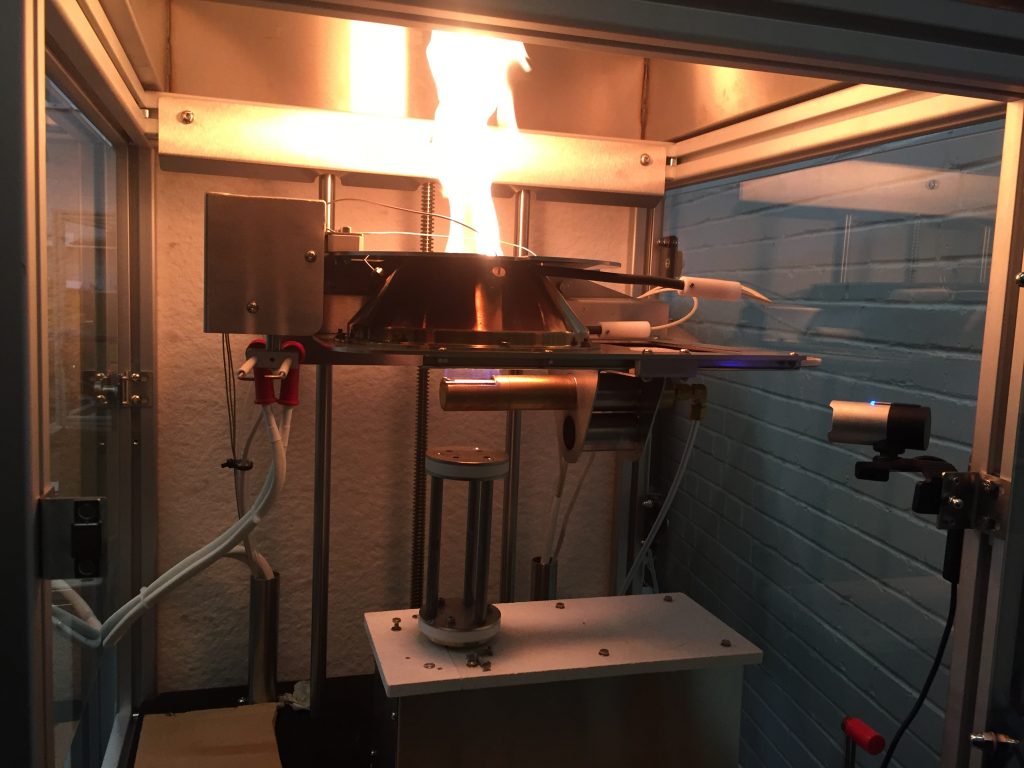

- 5000W Inconel Tubular Heater

- PID temperature control

- Spark Igniter

- Specimen shield

- Computerised automated setting of heat flux level

- All stainless steel construction of Hood, ducting, orifice plate, ring sampling probe, and exhaust blower

- Variable speed blower

- Specimen holders (stainless steel)

- Smoke measuring system

- Helium-neon laser light source

- Auto calibration and scaling

- Oxygen analyzer

- Paramagnetic

- 0-25% range

- All stainless steel construction of Hood, ducting, orifice plate, ring sampling probe, and exhaust blower

- Gas sampling and analysis system

- CO2 analyser

- Non-dispersive infra-red

- 0-10% range (v/v)

- CO2 analyser

- 0-1.0% range (v/v)

- Data Calibration and Reporting

- High Accuracy Data acquisition

- Minimum Scan rate – 4 scans per second! Fastest on the market

- Simplified Auto-calibration software

- Data output in Microsoft Excel workbook

- User customisation of calculations, graph generation and reporting

Technical Data & Requirements

Electrical: 230 volts 50/60 Hz – 45 Amp – Nominal 7500 Watts

Ambient Temperature: Operating 10°C to 35°C

Gas Supplies:

Methane: The ISO 5660 standard requires the methane calibration gas to be of at least 99.5% purity. The regulator attached to the methane cylinder must be capable of supplying 20 litres per minute with an adjustable line pressure of 0 – 430 kPa (0 – 60 psig).

During the Cone Calorimeter’s commissioning stages, enough methane should be available for at least 40 minutes of burning at 20 litres per minute at STP (i.e. approximately 800 litres).

For normal working practice (daily calibration), expect to use between 30 and 100 litres of methane every working day.

Oxygen Analyser Zero Gas: Oxygen-free’ nitrogen must be available to zero the oxygen analyser. The line must be capable of supplying a maximum of 7 l/min with typical line pressures of about 103 kPa (15 psig).

The nitrogen must be dried before being passed through the oxygen analyser. This is most easily achieved by the use of an in-line column containing a desiccant such as silica gel regularly reactivated or replaced.

Water supply: The Cone Calorimeter requires cooling water for the heat flux gauge and the cold trap. It is a very minimal flow; a pressure regulator set at 250 kPa (35 psi) should be provided if the mains pressure is likely to undergo surges greater than this value.

Cooling water may be taken directly from the mains supply provided that it is clean and controllable. The water should be cooler than 25°C. A drain line is also required.

Dimensions: 1830mm (W) x 2650mm x (H) x 1150mm (D)

Shipping weight – 550 Kg

Fume extraction: Hood capable of 50 l/s evacuation

ISO 5660, BS476 PART 15, ASTM E 1354, ASTM E 1354, ASTM E 1550, ASTM E 1740, ASTM D 5485, ASTM D 6113, NFPA 271, NFPA 264, CAN ULC 135