The idenPol QA2 has three modes of operation:

Comparison, Confirmation and Identification. The Identification mode of the system can be used to identify an unknown plastic material by comparing its behaviour to a library of known thermoplastics (PE, PP, PA6 etc) that is built into the system software.

The idenfication of an unknown material requires a match of several thermophysical properties that are measured as the unknown plastic is heated, these are:

- Amorphicity - a measure of the degree of orientation of the polymer chains.

- Glass transition temperature - the temperature at which non crystalline material starts to become mobile and soften.

- Melting point temperature - the temperature at which crystalline material starts to melt.

- End point temperature - the temperature at which the plastic loses mechanical integrity.

Although there are many methods available to confirm the identy of a plastic material, few are as quick—or as cheap—as that of the identiPol. Best of all, an unskilled and untrained operator can be shown how to use the system in just a few minutes.

The test sample was prepared in the standard way. A couple of plastic granules were first moulded within the identiPol QA2 to give a consistent material for measurement. This was then followed by a second heating regime to measure the properties of the unknown sample.

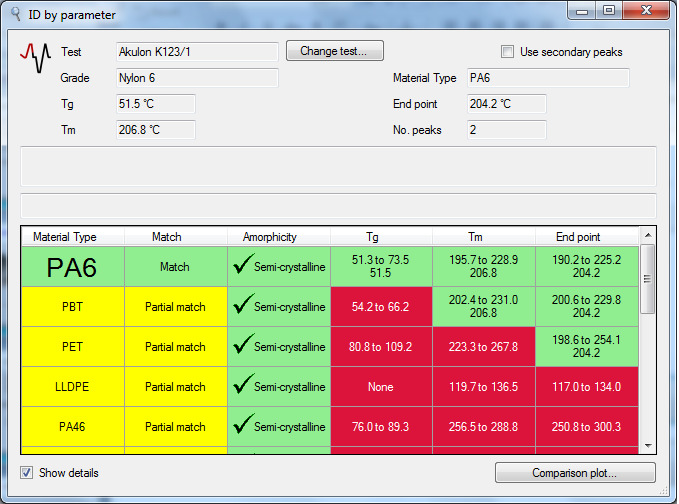

The following parameters were measured:

- Amorphicity = Semi-crystalline

- Glass Transition = 51.5°C

- Melting Point = 206.8°C

- End Point = 204.2°C

Following the test the software displays a table of the closest matches to the unknown.

The table below illustrates how the unknown plastic has been correctly and unambiguously identified as PA6 (Nylon 6 - a material widely used for its high tensile strength), based upon matching the measured parameters with the library stored within the system’s memory.

The entire test, from selecting a couple of plastic granules, to prinng out a certificate of analysis, takes only 15-20 minutes.