Differentiating new and recycled PP granules in the production environment

One of the benefits of working with thermoplastic granules is the opportunity to re-use and recycle material simply by heating and blending. Increasingly, to reduce waste material costs, failed material is often reworked and added back into the production process. But how can you differentiate between ‘new’ and partially ‘recycled’ material when they look identical?

In a laboratory there is a wide range of - frequently expensive - instrumentation available to answer this question, but even here it can be difficult and time consuming to establish the differences between these two types of plastic granule. One approach would be to use FTIR, but this technique becomes more difficult if the granule is filled or coloured by a masterbatch as this then requires some clever sample handling prior to loading into the FTIR in order for it to work. An alternative might be DSC, where the melting range of the plastic is measured and the presence of filler poses no problems for the analysis. But what if the DSC melting profiles look identical – and you know one of the samples contains an amount of reworked material – where do you turn then?

One approach to the above problem is to measure the Oxidative Induction Time (OIT) or Oxidative Onset Temperature (OOT) of the plastic. These are recognised test methods and many international standards exist to ensure compatibility and consistency in there measurement. The OOT is established whilst heating the material through the melting range and noting the temperature for the onset of decomposition, whereas the OIT is measured by heating to a fixed temperature above the melting point and measuring the time taken for the onset of decomposition.

The identiPol OIT can be used to measure either of these parameters and is ideally suited to the production environment where all experimental conditions and calculations are automated for the non-technical operator.

Of course, the these tests can also be performed on a DSC but as this involves heating the material through to degradation, can result in significant cleaning time afterwards. Also, typically a DSC would be used to hold the plastic at a steady elevated temperature (~200°C) and wait until the material decomposes – which may take 20 to 30minutes, or more – hardly a quick and convenient test for the production environment.

Originally the OIT test was used by scientists to detect differences in the molecular weight range of a plastic, which could then be related to mechanical properties. As PP is stabilised by the addition of various antioxidant packages the OIT / OOT test can be used to check for the presence and amount of antioxidant blended into the raw PP.

Using the identiPol OIT to measure the dynamic (heating) OOT temperature is a quick and simple process and can be operated by non-technical staff with minimum training.

PP samples (courtesy of Innovia Films Ltd) for analysis using the identiPol OIT. These samples had already been analysed by DSC to the melting point and found to be identical. This was confirmed by using an identiPol QA2 system which resulted in a PASS being allocated to all PP four samples based upon their QIS value.

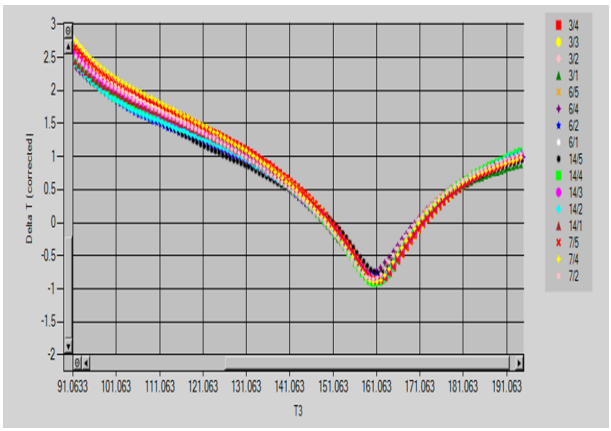

Further investigation was carried out by performing a Dynamic Oxidation test (ISO-11357-6-2008). This revealed important differences. The Oxidative Onset Temperature (OOT) test was originally used to give a relative measure of molecular weight, for a given grade of material, the higher the OOT; the higher the molecular weight, given the absence of antioxidant additives.