A peel test is performed between two substrates bonded together with an adhesive. The substrates may be both flexible or one may be flexible while the other is rigid. The adhesive itself will generally take the form of a thin layer between the two substrates such as the adhesive located on the underside of a piece of tape that has been placed against a steel plate.

Purpose of Peel Tests:

Generally the goal of a peel test is to determine the adhesive strength of the material or the strength of the adhesive bond between two materials. This adhesive strength may be referred to as the “stickiness” of a material as it is a measure of the samples resistance to separation from one another after the adhesive has been applied. This measured value may then be used to determine if the adhesive bond is strong enough or too strong for the application and whether a different adhesive or bonding process is needed.

Learn about Peel Test Fixtures...

Common Peel Tests:

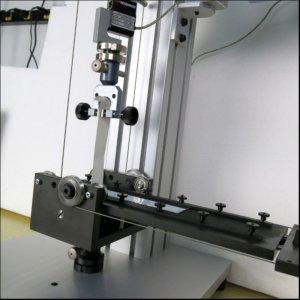

The most common types of peel tests for the measuring of adhesive strength are the T-peel, 90 degree peel, and the 180 degree peel. The T-peel test is a type of tensile test performed upon two flexible substrates that have been bonded together and placed into peel test grips such that one substrate sticks up and the other sticks down while the bonded area sticks out horizontally so that the entire setup forms a “T” shape. The 90 degree test requires a 90 degree peel test fixture to determine the adhesive strength between a flexible (tape) and rigid substrate (plate), where the plate lies horizontally with the gripped end of the tape sticking up perpendicular while the rest is bonded to the plate so that it forms an “L” shape. The 180 degree test is similar to the 90 degree peel test except that the bonded area between the tape and plate is placed vertically between the peel test grips while the free end of the of plate is gripped by the bottom and the free end of the tape is gripped by the top so that it forms a tight “U” shape.

Types of Materials:

A peel test is commonly used to measure the adhesive strength between the bonded surface of two flexible substrates or a flexible and rigid substrate. The flexible substrate often consists of tape, film, thin plastic material, rubber, or other polymers, whereas the rigid substrate is commonly but not limited to a type of metal, rigid plastic or composite. The conditions under which these materials are tested are composed of various combinations of pretreatment, temperature and speed of testing depending upon the standard test method used to guide the testing process.

Learn about Peel Test Fixtures...

Selected Test Standards

- ASTM B533 Peel Metal Coating Test Equipment

- ASTM C794 Adhesion-in-Peel Elastomeric Joint Sealants Test Equipment

- ASTM D1781 Climbing Drum Peel Test Equipment for Adhesives

- ASTM D1876 T Peel Resistance Test Equipment for Adhesives

- ASTM D2979 Tack Adhesive Testing Machine

- ASTM D3167 Peel Resistance Adhesives Test Equipment

- ASTM D3330 - Peel Adhesion Pressure Sensitive Adhesive Tapes

- ASTM D429 - Rubber to Metal Adhesion Test Equipment

- ASTM D5170 T Peel Strength of Hook and Loop Touch Velcro Fasteners

- ASTM D6252 90 Degree Peel Adhesion Equipment for Pressure-Sensitive Label Stocks

- ASTM D6862 90 Degree Peel Resistance Test Equipment for Adhesives

- ASTM D903 180 degree Peel Strip Strength of Adhesive Bonds

- ASTM F88 Seal Strength Testing Equipment for Flexible Barrier Materials

- ISO 4578 Peel Resistance Testing Adhesives

- FTM-1 Peel adhesion (180 degrees) test equipment

- PSTC-101 Peel Adhesion Test Equipment for Pressure-Sensitive Tape (PSA)

Selected Applications

- Medical Device Package Seal Strength Testing

- Peel Adhesion Bond Strength of Coating Materials

- Peel Strength of Film Seals in Medical Device Packages

- Peel Adhesion Bond Strength of Labels

- Adhesive Tape Peel Testing

- Testing Peel Adhesion of Labels and Tapes

- T-Peel Tests for Adhesives

- Climbing Drum Peel Tests with Sandwich Specimens

- Peel Adhesion 90 Degree Testing per FTM 2

- 180 Degree Peel Test of Metal Foil

- 180 Degree Peel Adhesion Credit Card Test

- Peel Testing Adhesion of Labels Per ASTM D6252

- Tape Testing in Accordance with ASTM D3330

- Textile Peel Test Equipment

- Touch and Close Fastener Peel Strength

- Rubber Tensile Adhesion Peel per ASTM D413 & ISO 36

- 180 Degree Peel Testing for Plastic Film

- Pressure Sensitive Adhesive & Tape Loop Tack Test Equipment

- Tensile, Shear, and Peel of Epoxy and Glue Testing Equipment

- Adhesive Peel Resistance by T-Peel Test

- T-Peel Strength of Tissue Adhesives

- Self Adhesive Tape Peel Adhesion

- T-Peel Test of Flexible to Flexible Bonded Assemblies

- Adhesion Strength of Rubber to Textile Fabric

- Adhesive Peel Stripping Strength of Bonds

- Coating Adhesion of Rubber or Plastic-Coated Fabric

- Metal Electroplated Plastics Testing

- Packaging Seal Strength Testing Equipment

- Peel Strength Seals Used in Food Packaging Test Equipment

- Rubber to Metal Adhesion Testing

- Seal Strength Testing for Flexible Medical Packaging

- Tape Peel Adhesion Test Fixtures

- Window Glass Adhesive Tests

- Package Seal Peel Testing