Cirrus

The Cirrus is a single nozzle atmospheric plasma treatment system ideally suited to surface activation, cleaning and modification of a wide range of materials including polymers, metals, glass and ceramics.

The Cirrus is extremely simple to operate via the front panel soft-keypad and can also be interfaced with external control equipment using the rear panel Sub-D connector providing a variety of I/O control inputs and status read-back to ensure seamless operation with production lines or robot cells.

The Cirrus operates frorm a standard single-phase electrical outlet and require only compressed air for operation.

The compact controller features an interlocked airflow regulation unit as standard so that no ancillary equipment is required.

Atmospheric Plasma Advantages

|

Atmospheric plasma systems address a range of specific treatments & material treatments including; plasma cleaning, plasma surface activation to improve adhesion, PEEK & other engineering polymers, PCBs, metals, ceramics and glass. |

|

|

|

PROCESS CONTROL

Easy operation

The compact control unit can be operated manually or interfaced with existing control equipment. Plasma start and stop signals are supplied via a rear panel Sub-D connector. All important parameters are available on the same connector for read-back and monitoring.

Typical Process Results

Images show increased wettability on metal and polymer samples following plasma treatment.

PLASMA ENVIRONMENT

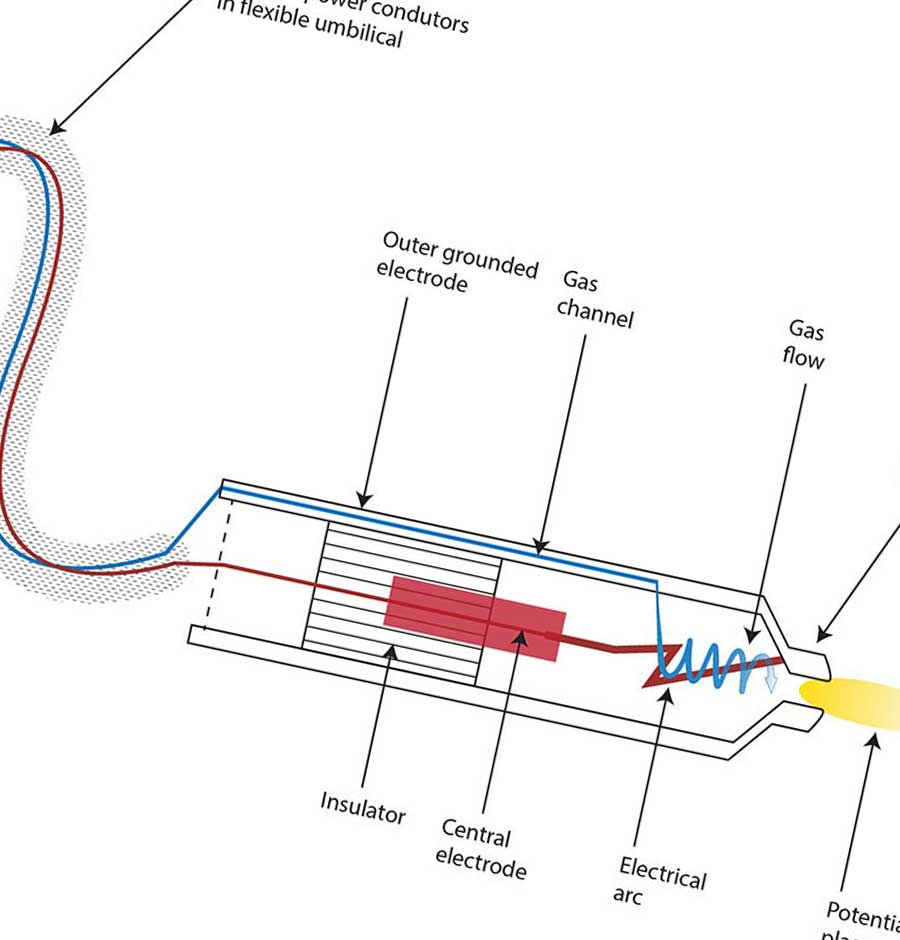

Atmospheric Plasma Applicators

The Cirrus delivers a ~10mm diameter plasma plume directly to the place where it’s required. The compressed air plasma has the effect of microscopically ‘sandblasting’ the surface whilst simultaneously chemically activating it.

Our proprietary, high stability plasma power generator allows for high line speeds when operated as part of a continuous processing facility.

The functionality of the Cirrus and Nimbus has been extended by the introduction of two new application-specific nozzle attachments. These are user-replaceable and can be supplied with a new system order or for retro-fitting to an existing system.

Mode

The ‘Mode’ nozzle is standard and suits 95% of all plasma pre-treatment applications

Finite

Our ‘Finite’ nozzle is best suited to confined areas or where a longer reach is needed, for example when treating channels or spaces between components.

BENEFITS

Versatility

The Cirrus produces a 10-12mm diameter jet of reactive plasma species which are highly efficient at removing hydrocarbon surface contamination and rendering a surface hydrophilic and suitable for subsequent processing, e.g. bonding, printing etc.

Repeatable and Reliable

The Cirrus system only needs a compressed air supply for operation. Plasma parameters and gas delivery are continuously monitored and controlled to deliver the same result irrespective of changes in gas delivery characteristics. The unit features a number of electrical and compressed air safety interlocks that ensure long term, trouble-free operation.

The Nimbus extends the overall functionality with dual plasma heads operating from the same single controller. [See our Nimbus Model page for details].

ROBOT

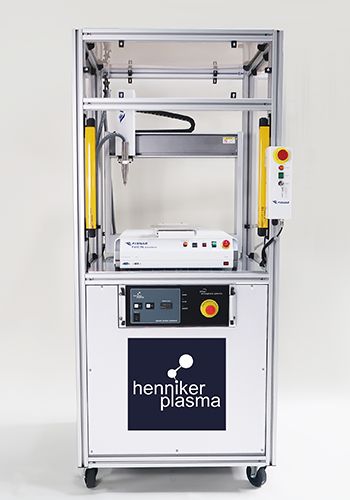

Robot Motion Automated System

The atmospheric systems can be supplied integrated with a 3-axis robot with up to 500mm by 500mm working area and 150mm of Z-axis movement. Includes stop/start box and teach pendant. manuals on CD, mains lead, I/O cable between robot and plasma unit.

Enclosure optional/cart-mounted:

The robot is available in either desktop or cart-mounted versions with optional guard frame and safety light curtain interlock.

|

|

SPECIFICATION

Technical Specifications |

||||||

|

Cirrus Atmospheric Plasma Treatment Systems |

||||||

|

CONTROLLER |

||||||

|

Dimensions |

W 483mm x H 177mm x L 451mm (+50mm on rear for cables) |

|||||

|

Weight |

~10kg, including plasma nozzle |

|||||

|

PLASMA NOZZLE |

||||||

|

Connection |

3m flexible umbilical to controller rear |

|||||

|

Weight |

~0.5kg |

|||||

|

Dimensions |

Ø 32mm x L 210mm |

|||||

|

Treatment width |

~10-12mm with standard applicator "mode" nozzle |

|||||

|

Gas/HV supply tube |

PVC-protection conduit |

|||||

|

PLASMA POWER SUPPLY |

||||||

|

Power |

300W, nominal |

|||||

|

Frequency |

40 kHz |

|||||

|

Interface |

Front panel - soft key pad |

|||||

|

Control |

Manual mode with plasma switch from the front panel or remote mode through SUB-D connector on the rear panel (plasma on/off). Automatic process control by plasma current and gas pressure control (on-board as standard). |

|||||

|

Inputs/Outputs |

Inputs (24V) Remote Outputs (Normally Open Contacts) System Ready |

|||||

|

SERVICES |

||||||

|

Electrical |

90-250 VAC, 50-60Hz, 1000 VA (including pump), fused 6.3 A T / 10 A T |

|||||

|

Gas connection |

Dry and oil-free compressed air; 5 - 8 bar, approx. Gases 2000 l/h 6mm push-fit |

|||||

|

Power cord |

Suited to region |

|||||

|

Compliance |

CE - UKCA - ROHS - WEEE |

|||||

|

NOZZLE OPTIONS |

||||||

|

Finite nozzle |

~8-10mm treatment area, for narrow channels |

|||||

|

**Henniker strive for continuous improvement and specifications are subject to change without notice |

||||||