HPT-100 & HPT-200

HPT-100과 HPT-200은 마이크로프로세서 제어 방식의 벤치탑 플라즈마 처리 시스템으로, 폴리머, 금속, 유리, 세라믹 등 다양한 소재의 표면 활성화, 클리닝 및 표면개질에 이상적인 장비입니다.

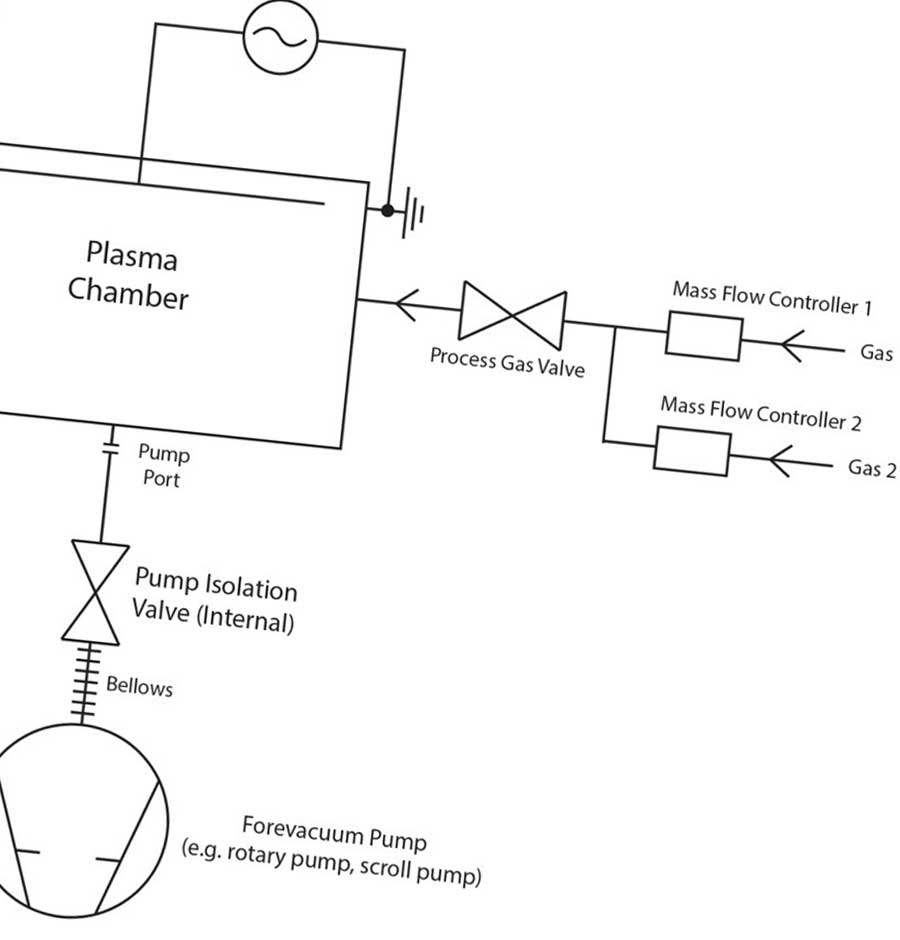

고정 가스 또는 싱글 가스 , 이중 가스 주입 버전과 온보드 가스믹싱 매니폴드를 갖춘 HPT-100/200 시스템은 공기, 산소, 수소, 아르곤, 질소 등 다양한 가스를 사용하여 최적화된 표면처리를 수행합니다.

옵션인 vapor inlet을 톻해 액체 전구체까지 사용할 수 있으며, 부식방지 버전을 다음과 같은 특정 재료 처리에 적용할 수 있어 선택의 폭이 더욱 넓습니다;

- Plasma cleaning

- Plasma surface activation to improve adhesion

- Functional plasma coatings

- Plasma etching

- PDMS & microfluidic devices

- PEEK & other engineering polymers

- PTFE

- Metals

- Ceramics

- Glass & optical devices

PROCESS RESULTS

TFT Colour touchscreen

Each system is supplied with a 5.7-inch colour touchscreen which provides a rich, user-friendly interface. Variables such as gas flow rate, pressure, power level and plasma processing time can be freely set and then stored to produce a fully interlocked process cycle from a single keypress. A handy status display and end of process audible alarm informs the user of every step in the process.

Plasma Cleaning Example

-

Material : HDPE

-

Air plasma

-

90 seconds

Before plasma treatment

After plasma treatment

PLASMA ENVIRONMENT

Vacuum chamber & power

The HPT-100 system features a 100mm diameter plasma process chamber in stainless steel with vacuum compatible materials throughout.

The HPT-200 features a larger capacity 150mm diameter plasma process chamber to accomodate more samples or larger samples.

Henniker's proprietary, high stability HPS plasma generator is continuously variable over the entire 0-100W/0-200W power range rather than being limited to discreet levels, delivering much finer control when processing delicate materials.

BENEFITS

Versatility

Each system has a range of gas inlet options to suit budget and application; fixed, single MFC, dual MFC and vapour delivery. The units can be prepared so that either option can be added at a later time if required, ensuring that future requirements can be accommodated without expensive reconfiguration.

Repeatable and Reliable

With precision flow control and integrated pressure gauge, the 100 & 200 models deliver unmatched reliability & repeatability by removing common errors in gas flow and gas type settings which will be familiar to users of equivalent equipment that utilise manual needle valves.

BENEFITS

|

|

SPECFICATION

Technical Specifications |

||||||

|

HPT-100 / HPT-200 Plasma Treatment Systems |

||||||

|

ENCLOSURE |

||||||

| Dimensions | HPT-100 / HPT-200 - W 520mm x H 286mm x L 550mm (+50mm on rear for cables) | |||||

| Weight |

HPT-100 - ~22kg HPT-200 - ~23kg |

|||||

|

CHAMBER |

||||||

| Material | Stainless Steel | |||||

| Form | Cylindrical | |||||

| Dimensions |

HPT-100 - 100mm dia. x 280mm L HPT-200 - 150mm dia. x 280mm L |

|||||

|

REMOVABLE PARTS CARRIER |

||||||

| Material | Aluminium | |||||

| Material options | Stainless steel | |||||

| Form | Flat tray | |||||

| Form options | Perforated tray, others to suit application | |||||

| Dimensions |

HPT-100 - 90mm W x 255mm L, others to suit application HPT-200 - 135mm W x 255mm L, others to suit application |

|||||

|

PLASMA POWER SUPPLY |

||||||

| Power |

HPT-100 - 0-100W, continuously variable output HPT-200 - 0-200W, continuously variable output |

|||||

| Frequency | 40 kHz | |||||

|

PROCESS CONTROL |

||||||

| Interface | 5.7” Colour TFT with recipe store | |||||

| Gas channel options | Fixed, x1 MFC or x2 MFC and x1 vapour inlet options | |||||

| Vent inlet | x1 | |||||

| Vent inlet options | soft ventilation option | |||||

| Connections | 6mm compression or 1/4" compression | |||||

| Process timer | 1sec – 99.59min | |||||

| Recipe Store | Stores up to 4 x recipes - with individual parameters | |||||

| Pressure gauge | Pirani sensor | |||||

| Vacuum pump | 3 to 6 m3/hr pumping speed | |||||

| Vacuum pump options | 2-stage rotary pump (air/inert gas), PFPE rotary pump (oxygen compatible), dry pumps. All pumps include exhaust filter and connections | |||||

|

SERVICES |

||||||

| Electrical | 90-250 VAC, 50-60Hz, 1200-1500 VA (including pump), fused 6.3 A T / 10 A T | |||||

| Power cord | Suited to region | |||||

| Compliance | CE – UKCA - ROHS - WEEE | |||||

|

**Henniker strive for continuous improvement and specifications are subject to change without notice |

||||||