Structural Testing Systems are each engineered to perform specialized tests with a specific set of sample types and test methods. These systems typically feature the use of multiple electrodynamic or servohydraulic actuators driven by a single or multichannel controller, application specific software and specially engineered fixturing. One of the major reasons why TestResources is so competitive in these applications is the versatility of our multichannel control system.

TestResources specializes in supplying two types of structural testing systems:

Automotive Test Systems |

Shake & Vibration Tables |

|

|

Automotive Test Systems

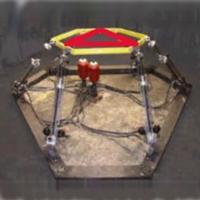

Automotive Multiaxis Shake Table

Multi-Axis Shake Tables (MAST System) are designed to perform durability and performance evaluation of automotive components and sub-assemblies. The computerized control system delivers user friendly, repeatable and reproducible operation with powerful application software that covers a wide range of testing requirements.

Ball Joint Test System

Ball Joint Test Systems perform durability and performance evaluation of ball joint systems by subjecting the specimen to tilt, rotation and axial loads. Servo torque motor, servohydraulic actuators, customized fixtures, and transducers simulate real test conditions with a computerized multichannel controller.

CV Joint Test System

CV Joint Test System performs constant velocity testing per SAE J 2028. The test system evaluates the quality of CV joints by simulating the actual movements in automobiles. Two mounting blocks bolted on the frame support a hydraulic motor and a torque load cell coupled with transducers for precision measurement and customized grips to hold the test specimen. The mounting blocks rotate (± 45°) and also move back and forth adjusting to the varying lengths of specimen.

Damper Test Machine

This machine is the industry's first high productivity shock absorber - strut - front-fork test system specially designed for use on damper production lines. B-303 helps ensure assembled parts meet specified performance specifications, and is result of over seven years of R&D with a focus on harmonizing production line test requirements for 2, 3 and 4-wheeler suspension components.

Elastomer & Engine Mount Test System

200 Series Single Column Shear Test Machines are capable of performing shear, compression, and tensile testing applications and feature higher travel and faster speed than the 100 Series. They are available with force capacities up to 5 kN (1,125 lbf) and speeds up to 2,500 mm/m (100 ipm). 200 Series load frames are compact and lightweight and apply to situations where lab table space is limited.

Shock Absorber, Damper Test Machine

This test machine is a high productivity shock absorber - strut - front-fork test system specially designed for use on damper production lines. The Shock Absorber Test Machine helps ensure assembled parts meet specified performance specifications, and is result of years of test machine R&D with a focus on meeting production line test requirements.

Steering Durability Test System

Steering Assembly Test Systems evaluate manual and power steering assemblies for durability and performance at frequencies to 50 Hz. The tests performed are in accordance with JASO C 717, IS 13476, JASO C717 and IS 14269. A servohydraulic torque motor with two linear actuators coupled with customized grips and transducers are mounted on moving blocks and accommodate specimens of varying length that are subjected to lateral and steering loads. The whole system is integrated onto a free standing self reacting T-slotted table.

Tire Testing System

Tire Test Systems evaluate both static and dynamic properties of tires, including durability under constant as well as road simulation loading. The test system features two carriages with spindle assemblies and can test two tires simultaneously. The wheel load is adjustable with maximum load of 100 kN (22,500 lbf) applied through two servohydraulic actuators at test speeds to 300 km/h (190 mph).

Shake & Vibration Tables

3 Axis Earthquake Shake Table Simulator

3-axes, 6-degrees-of-freedom shake tables are state-of-the-art solutions for seismic simulation, soil liquefaction and vibration tests on building models as well as for engineering qualification of equipment or its components and assemblies for earthquake and vibration resistance. The table enables rigid specimen mounting for transfer of required acceleration history. The center of gravity of the test object can be located anywhere within the working space of the table. Table motion is generated through precision dynamic synchronous control of all 8-actuators: 4-vertical, 4-horizontal.

Horizontal Uniaxial Vibration Table

Our Horizontal Uniaxial Vibration Table performs seismic simulation, solid liquefaction and vibration tests on models as well as for engineering qualification of components and assemblies for earthquake and vibration resistance. The table is designed with a natural frequency to exceed 100 Hz.

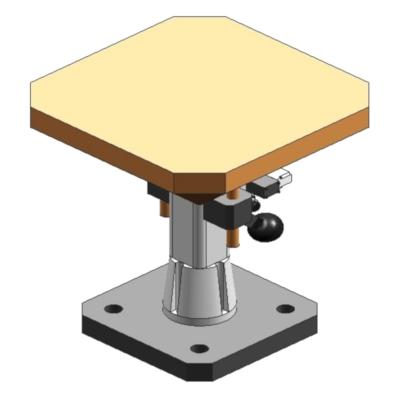

Vertical Vibration Table

The Vertical Vibration Table delivers vertical axis movement along a single Z axis. The machine is rated to 275 kg and frequencies in excess of 100 Hz. Vertical table movement is provided by means of a 50 kN (11,250 lbf) dynamic rated, double ended, double acting pedestal mount servo-hydraulic actuator.