Planar Biaxial Test Machines

Planar Biaxial Test Machine은 다축의 응력 상태를 재현하는 면 응력(in-plane stress) 생성 장비로서 각 평면에서 2축이 서로 마주 보도록 장착된 네 개의 액추에이터로 구성되어 있으며, 각 액추에이터는 4채널 서보 컨트롤러에 의해 독립적으로 제어되어 모션 또는 변형률, 하중의 독립적이고 동기화된 제어를 수행합니다. 각 액추에이터는 다른 세 개의 액추에이터와 함께 작동하여 원하는 2축 응력을 재현하도록 제어됩니다. 4축 시험장비라고도 불립니다. 8축의 옵션이 가능합니다.

TestResources사의 planar biaxial test system은 접촉식 신율계 또는 적절하게 구성된 DIC(digital image correlation) 비디오 카메라와 함께 구성될 수 있으며, 이를 통해 변형률 측정 제어가 가능합니다. 대부분의 응용 분야에는 전기식 액추에이터가 가장 적합합니다. 서보 유압식 액추에이터는 매우 높은 하중 및 까다로운 피로 시험 분야에 권장됩니다. 그러나 비교적 낮은 힘이 필요하고 시험이 준정적이거나 15Hz 미만인 경우, 서보 유압식 액추에이터보다 전기기계식 및 전기역학적 액추에이터가 선호되는 경향이 있습니다.

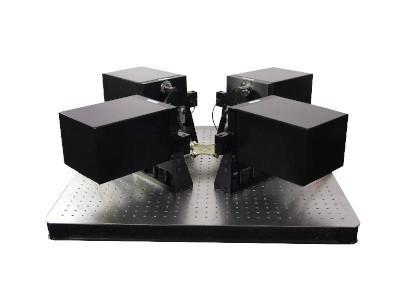

본 지면으로서 당사에서 취급하는 4축 인장강도시험기를 소개합니다. 연질 시료와 스트레처블 소재의 인장강도 측정에 용이합니다.

|

Series |

Type |

Max Force Capacity |

|---|---|---|

|

174 Series |

Electromechanical |

50 kN to 200 kN (11,250 lbf to 45,000 lbf) |

|

574 Series |

Electrodynamic |

100 N to 30 kN (22 lbf to 6,750 lbf) |

|

974 Series |

Servohydraulic |

50 kN to 2MN (11,250 lbf to 450 kip) |

Start by Selecting a Series

Low force biaxial test applications are suited to the 574 series electrodynamic tester, which is used in mechanical, biomedical, and materials engineering research. You can use this all electric dynamic modular test machine for applications such as hard foam, glass fabrics, textiles, sheet metal fastening, silicone elastomer, orthotropic plates and biological samples such as fibrous tissues, arterial walls, back disc tissues, skin, and heart valves. They are ideal for testing the mechanical properties of directionally oriented microstructures.

High force biaxial tests are commonly served by our 174 and 974 series test machines. The 174 includes an electromechanical actuator that can produce loads up to 200 kN (45,000 lbf) and quasi-static speeds up to 2 Hz. The 974 servohydraulic systems are used for higher forces and tests speeds. Test sample types include sheet metal, metal plate, aluminum alloys, composite laminates, fibre reinforced polymer composites, plate girders, cell core sandwich materials and reinforced concrete.

174 Series Planar Biaxial Test Machine

Max Force Capacity: 50 kN to 200 kN (11,250 lbf to 45,000 lbf)

Max Frequency: 2 Hz

The 174 series electromechanical planar biaxial test systems provide researchers with new abilities to characterize and evaluate quasi-static performance of high strength materials under planar biaxial loading conditions. You can perform both static and fatigue tests up to 2 Hz with the 174 series test system.

574 Series Planar Biaxial Test Machine

Max Force Capacity: 100 N to 30 kN (22 lbf to 6,750 lbf)

Max Frequency: 15 Hz

The 574 Series electrodynamic planar biaxial test systems provide researchers new abilities to characterize and evaluate quasi-static, dynamic and fatigue performance of low strength materials under planar biaxial loading conditions. With the 574 system, you can perform virtually any mechanical test used to characterize material properties.

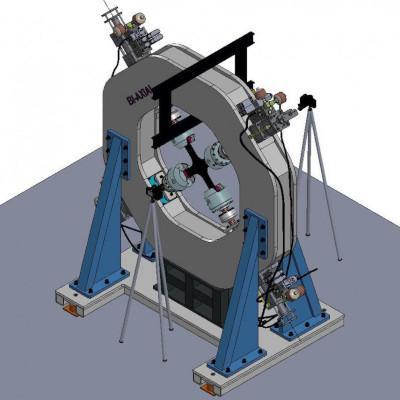

974 Series Planar Biaxial Test Machine

Max Force Capacity: 50 kN to 2MN (11,250 lbf to 450 kip)

Max Frequency: 30 Hz

The 974 Series servohydraulic planar biaxial test system enables static, dynamic, and fatigue tests on high strength square, rectangular and cruciform test samples. 974 systems are used for metal and composite fatigue and fracture and configured for higher force capacities and test speed capabilities.