SDCHN 435 can be used to determine the carbon, hydrogen and nitrogen content in coal, coke, food, soil, fertilizer etc in the fields of power plant, coal mine, metallurgy, petrochemical industry, steel factory, environmental industry and so on.

Self developed ultra low temperature drift TCD and thermalstatic diffusion type TCD ensure the stability of TC reference line (SDCHN435 elemental analyzeronly).

10 Patents. 7 Invention patents included. 35 samples autoloader

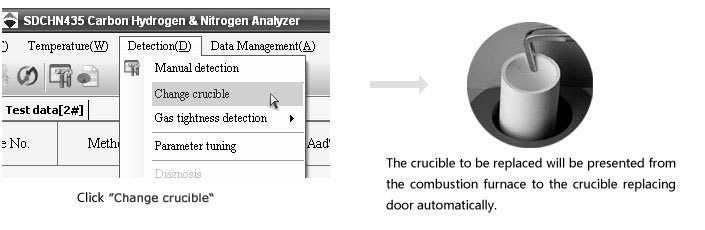

The only type of elemental analyzers with auto combustion crucible replacing device.

High automation and convenient operation

· It can replace the crucible automatically without disassemble or cooling. Just click on the software, then the crucible can be replaced automatically.

· Gas leak check is convenient and fast.

· With separate design of combustion furnace and reagent furnace, the reagent can be easily and safely replaced with the minimal amount of effort..

High level of Test Accuracy

· On relatively stable experimental conditions, calibrating once every three hours can meet the test requirements, China National Coal Quality Testing Center certified.

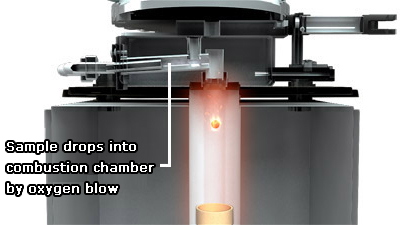

· Samples are carried into the combustion chamber by oxygen blow, which enables all the released gases to be captured and thus enables a higher level of test accuracy.

Humaniation Design and Convenient Operation

① Easy and convenient for gas leakage check, operators only need to click on the software.

② Convenient to replace the Furnace Reagent. With separate design of combustion furnace and reagent furnace, reagent can be easily and safely replaced with the minimal amount of effort.

③ Floor standing design with superior wheels and wheel locking device for all elemental analyzers, it’s convenient to shift the instrument from place to place.

④ Enlarged combustion crucible for elemental analyzercan greatly reduce the frequency of crucible changing.

Low cost of gases

· Oxygen with purity of 99.5% can meet the test requirement.

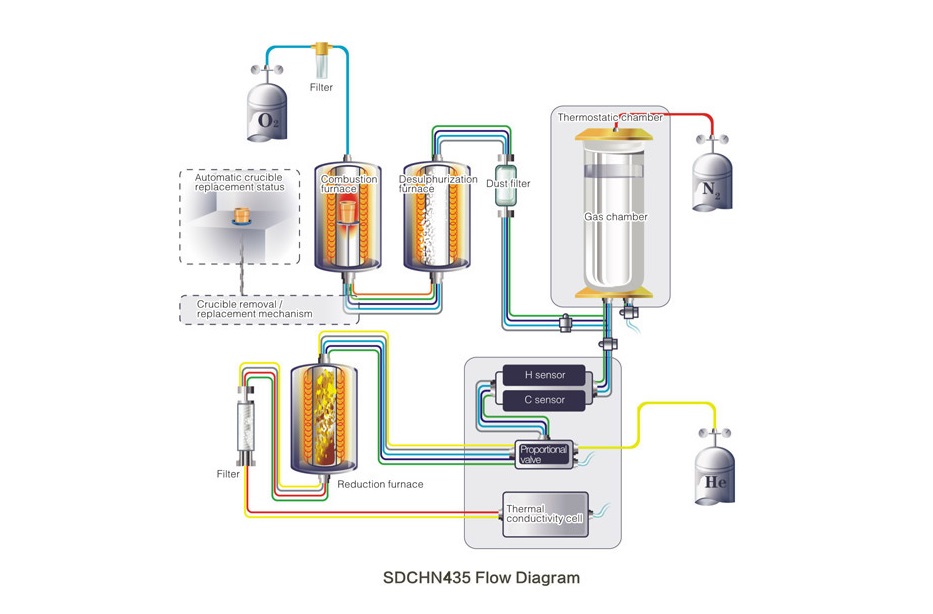

· With thermostatic gas chamber, the probability of gas leak and consumption of driving gas are lowered.

Intelligent control

· Easy-to-use Windows-based software

· Easy data handling, real time data can be transmitted by internal network.

· With CAN bus interface, several elemental analyzers can be controlled by a single PC without mutual influence.

· It can be connected with balance and network by standard interface RS232.

Conformance with Standards

ISO29541 Solid mineral fuels : Determination of total carbon, hydrogen and nitrogen content- Instrumental method

ASTM D5373-02 Standard Test Method for Instrumental Determination of Carbon, Hydrogen, and Nitrogen in Laboratory Samples of Coal

Specifications:

|

Description |

SDCHN435 |

|

Measuring Range |

C(0.02%~100%) H(0.02%~50%) N(0.01%~50%) |

|

Reproducibility |

Cd≤1.00% Hd≤0.25% Nd≤0.15% |

|

Repeatability |

Cad≤0.5% Had≤0.15% Nad≤0.08% |

|

Max.Sample Quantity |

34 |

|

Analysis time |

≤5min/Sample |

|

Sample Mass |

75~105mg(Recommended:100mg) |

|

Analysis Method |

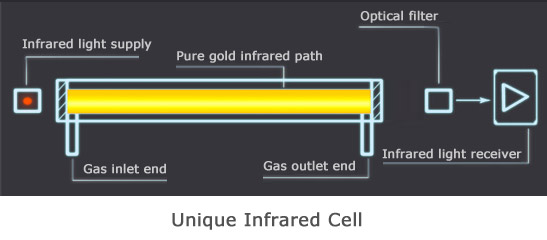

CH:Infrared Absorption N:Thermal Conduction |

|

Combustion Supporting Gas |

Oxygen Purity:≥99.5% Pressure:≥1MPa |

|

Carrier Gas |

Helium Purity:≥99.99% Pressure:≥1MPa |

|

Driving Gas |

Nitrogen / Dry Compressed Air Pressure:≥1MPa |

|

Preheating Time |

<2.5hour |

|

Sample Adding/Replacing Function |

Available |

|

Auto Analysis |

Yes |

|

Crucible Replacing |

Automatic |

|

Furnace Temperature |

Combination Furnace,950℃±5℃ Reduction Furnace:700℃±5℃ |

|

Air Tightness Detection |

Automatic |

|

Humidity |

20%to 85%, non-condensing |

|

Ambient Temperature |

15 ℃ to 28℃ |

|

Power requirement |

220 V(-15%~10%)50/60Hz |

|

Max.Power |

4.5kW |

|

Dimensions |

680*630*980mm |

|

Weight |

204kg |

|

Advance Calculation |

Yes |

|

Analysis Report |

Yes |

|

Statistics Report |

Yes |

|

System Monitor |

Yes |

| Standards | AS 1038.6.4, ASTM D5373, ASTM D5291, ISO 16634, ISO 16948, ISO 29541, EN 15407,EN ISO 16948:2015-0, UNI 15104, UNI CEN/TS 15407 |