Get exactly what you need, quickly and economically!

You shouldn't have to choose from cookie cutter test machines if your test is anything but ordinary. Thanks to our modular design you have the power and flexibility to design and build a machine that fits your unique application and budget. You no longer have to pay for things that you will never need or use because those features come 'standard' with the mass-produced machines. We have thousands of products and we are continuously adding new products based on our customer's needs.

Modified and Custom Testing Capabilities

|

Can't find a system that meets your needs? It happens. That's why we give you the flexibility to co-engineer your own system! Need a design tweak? With our large number of standard products and a massive number of modular sub-assemblies, we can tweak an existing design quickly and economically. If you need a blank sheet of paper, start from scratch design, we can do that too. We have machines that are completely modular for when you need a simple tweak and we design optimized test machines for specific applications when you need a little more customization. Get exactly what you need, quickly and economically. Need Something Special?

|

Expert Application Engineering

After thousands of applications in over 50 countries, we have seen a thing or two. Our application engineers have experience in all things testing and testing all things. When you work with us, you get experienced engineers to solve your testing and budgetary challenges. That's just what we do.

Okay, we are biased but really we have done some amazing things, and we can help you do the same!

A Few Examples of Our Capabilities:

Airplane Landing Gear Test System

|

Technical Challenges

Budgetary Challenge

|

Amazing Growing Test Machine

|

Technical Challenges

Budgetary Challenge

|

2 for 1 Luer Tester

|

Technical Challenge

Budgetary Challenge

|

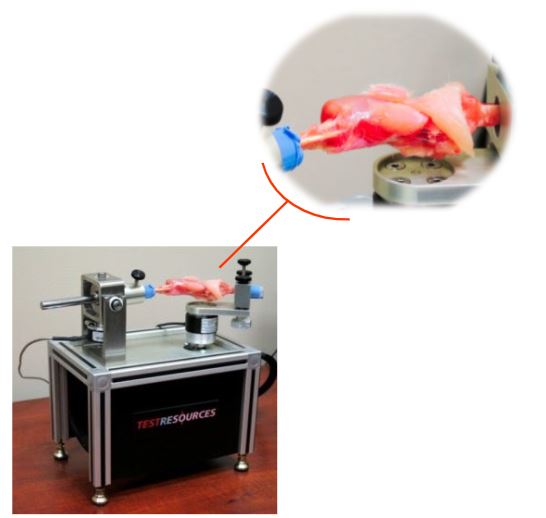

Rabbit Knee Tester

|

“I needed a method of measuring accurate data results for the angle and torque-free motion of a rabbit’s knee. TestResources took the time to understand what I needed and came up with an effective and budget-friendly solution.” Dr. Andrzej Fertala, Thomas Jefferson University Technical Challenges

Budgetary Challenge

|

Foam Seat Cushion Tester

|

Technical Challenges

Budgetary Challenge

|

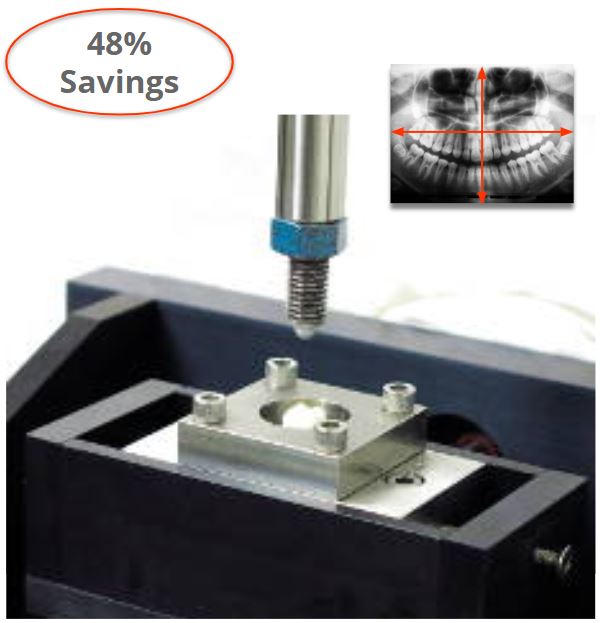

Mastication Simulation: Dental Implants

|

Technical Challenges

Budgetary Challenge

|

Cadaver Test Machine

|

Technical Challenges

Budgetary Challenge

|

Electric Car Component Tester

|

Technical Challnges

Budgetary Challenge

|

Nuclear Rod Tester

|

Technical Challenges

Budgetary Challenge

|

Couch Cushion Test Machine

|

Features

|

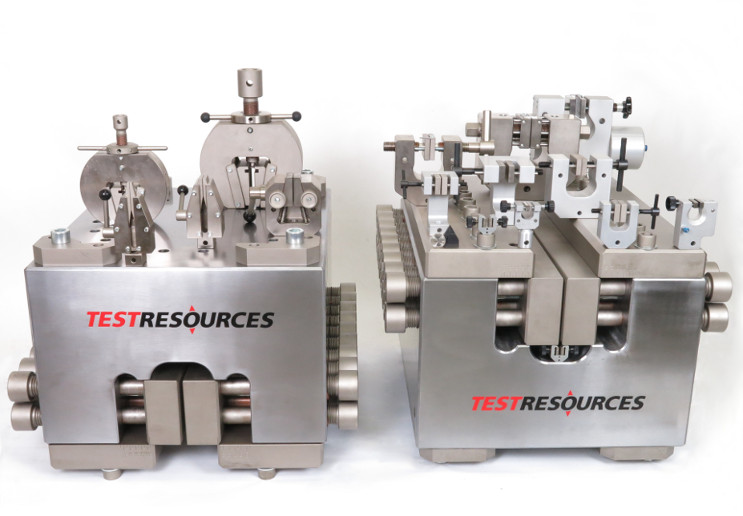

Planar Biaxial Tester

| This customer came to us to improve their internally built machine with something capable of higher forces and more control features. The goal was to quantify material properties of various textile and geotextile material to improve and define product capabilities. | |

|

The Solution

|

|

Water Management Pipe Tester

|

A start up pipe manufacturing company within the oil and gas industry came to us for an affordable system that could accommodate a wide range of pipe sizes for developing water management systems. Customer Requirements

|

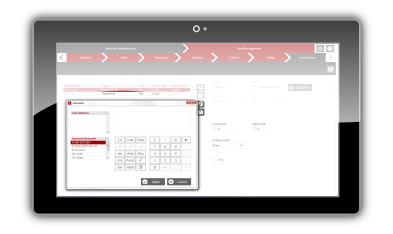

Test Machine Controls

|

Newton is TestResources' powerful computer-based hardware, software, and control platform. Newton is the latest technology on the market that gives you the ability to purchase only the capabilities and features you currently need while allowing you to easily and affordably expand the system's capabilities to meet all future needs. Your controller and software can be easily enhanced at any time by adding standard or customized features. That's the beauty of Newton!

Add new features & capabilities at any time - Choose from 190+ features |

Start with a preconfigured package that has been optomized for common applications or build your own package feature by feature.

- TestVideo Recording & Playback

- TestCalc Real-time & Post Test

- ASTM A370 Software Module

- ASTM D412 Software Module

- ASTM D638 Software Module

- ASTM D790 Software Module

- ASTM E8 Software Module

- ASTM F88 Software Module

- … And many more!

Need a custom calculation or a custom application developed? Need a second control channel added to your package? Just ask! We can completely customize your package and features to meet any test requirements both now and down the road.

Custom Accessories

|

Choose from thousands of accessories or we will design one with you to meet your specific application. From silk thread to air plane landing gear, we have the accessories you need to perform your test effectively.

Solving technical challenges and saving test engineers money since 1998. TestResources is a trusted partner to engineers worldwide who seek our technical expertise to accurately design test systems. Work with us and you will have access to experienced application engineers who partner with you to design high performance solutions. If you need a test machine but have a limited budget or require specialized functionality, we have a solution for you! |