TestResources와 (주)연진에스텍은 매우 다양한 환경 챔버 및 오븐을 제작 설계, 판매하고 있습니다. 당사는 거의 모 든 가상의 비 주변 테스트 조건 (vertually non-ambient test condition)에 대한 솔루션을 제공합니다. Chamber, grip, pull rod (냉각 및 표준), 챔버 이동을 위한 신율계 (extensometer) 및 cart에 이르기까지 모든 환경 시험 필요 요구 사항을 처리 할 수 있습니다.

든 가상의 비 주변 테스트 조건 (vertually non-ambient test condition)에 대한 솔루션을 제공합니다. Chamber, grip, pull rod (냉각 및 표준), 챔버 이동을 위한 신율계 (extensometer) 및 cart에 이르기까지 모든 환경 시험 필요 요구 사항을 처리 할 수 있습니다.

| Load Frame Types | Single Column, Dual Column or Biaxial |

| Temperature Range | −185°C to +620°C (-300°F to 1150°F) |

| Humidity Range | -40°C to +150°C (-40°F to 300°F), 10 to 90% Relative Humidity |

| Interior Width Range | 152.4 mm to 1524 mm (6 in to 60 in) |

| Interior Height Range | 254 mm to 2286 mm (10 in to 90 in) |

| Interior Depth Range | 152.4 mm to 1524 mm (6 in to 60 in) |

Environmental Chambers Designed to Customer Requirements

Due to the unique nature of environmental testing, all chambers are designed to customer requirements in a wide variety of widths, depths, heights and configurations in order to fit the test space and specifications. Multi-sample fixturing can be accommodated within one chamber with the proper configuration. Getting the right chamber dimensions is an important step in the configuration process. Your sample, grips and pull rods might all fit, but once you actually begin running your test, you might end up with a deficit. We take extra time at this step to ensure your chamber meets all of your test space requirements including sample elongation, maximum travel and load frame restrictions.

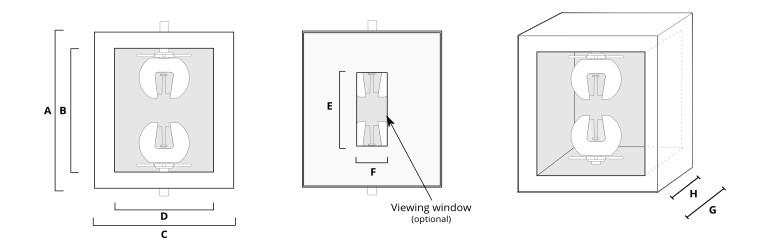

| A | External Height |

| B | Internal Height |

| C | External Width |

| D | Internal Width |

| E | Viewing Window Height (Optional) |

| F | Viewing Window Width (Optional) |

| G | External Depth |

| H | Internal Depth |

Low, High and Humidity Chambers

Testing at non-ambient temperatures adds a new layer of complexity to your test. Productivity, cost of ownership, ease of use, and operator safety are all affected by the need to test at high and low temperatures and should be taken into consideration. A properly configured temperature chamber will provide optimized heating and/or cooling rates, reduced thermal gradients, and superior thermal stability.

Environmental Chamber Types:

- Low Temperature

- High Temperature

- Low/High Temperature

- Humidity

Special Features and Options:

- Heated window options for low temperature testing, so you do not have to deal with frost build up on windows

- Fast ramping to set point temperatures

- Forced air convection blower for better thermal homogenization

- Close fit load train port inserts means less thermal losses, better temperature consistency and less thermal gradients

- Temperature compensated load cells, lessen the thermal effects on load readings

- Water cooled pull rod options, that will limit thermal effects on the load cell

- Optional carts for moving the chamber in and out of the load frame when not in use. Eliminating the possibility of operator injuries from lifting heavy equipment

- Breakaway chamber floor option to reduce the risk of chamber destruction in the case of a collision with a bottom mount hydraulic actuator

- Superior insulation, resulting in cooler external temperatures

- Door Interlocks that cut power to the heaters or cooling devices and fan, when opened to limit exposure to the operator

- Rear protection cover for operator safety

|

|

|

|

|

|

|

|

Single Column, Dual Column or Biaxial Load Frames for Environmental Testing

Dual Column testing is the most common type of load frame used for environmental testing but it’s certainly not the only type. Not only does your sample, grips and pull rods have to fit inside the chamber but your chamber needs to fit within the confines of your test machine’s load frames. Chambers are designed to fit between the columns of your materials testing machine.

If your test requires you to frequently move the chamber, we offer optional sliding rails and U shaped load train port inserts which make moving the chamber in and out of the load frame a breeze.

Complete Solutions and Expectations

When you partner with TestResources, you can rest assured that you will have the best solution for your testing needs at the most cost-effective price available. In just a few short questions about your application, requirements and restrictions, our engineers are able to propose a cost-effective solution that meets your test specifications and solves challenges that you may not foresee. We take the time to find out what is important to you and the success of your test.

|

|

|

|

|

|

|

|

Contact one of our experienced application engineers to configure the best solution for testing at non-ambient temperatures and humid environments.

Product Literature |

|---|