Different Shapes of Sputtering Targets

(주)연진에스텍은 Planar (flat) Target과 Rotary (cylindrical) Target, Circular Target 및 Ring Target 등 대부분의 증착 공정에 부합하는 다양한 형태의 스퍼터링 타겟을 제공하며, 타겟 크기의 커스터마이즈가 가능합니다.

Lanthanum Strontium Cobalt Oxide Target (LSCO)

LSCO Product Overview

The Lanthanum Strontium Cobalt Oxide (LSCO) Target is engineered for high-performance applications, offering exceptional electrical conductivity, robust catalytic activity, and remarkable stability under elevated temperatures. Composed of lanthanum, strontium, and cobalt, LSCO features a perovskite crystal structure that enhances its conductivity, making it ideal for solid oxide fuel cells (SOFCs) and catalytic processes. The inclusion of cobalt boosts its ability to facilitate oxygen reduction reactions, while strontium improves ionic conductivity, leading to superior electrochemical performance. LSCO remains stable in high-temperature environments, ensuring long-term durability and consistent performance. Its compatibility with sputtering processes allows for the deposition of uniform, high-quality thin films, essential for advanced electronic and energy applications.

LSCO Specifications

Material: Lanthanum Strontium Cobalt Oxide (LSCO)

Purity: 99.9%

Form: Planar Disc

Chemical Composition (%):

| Element | Content |

|---|---|

| La | 80 |

| Sr | 10 |

| CoO | 10 |

Note: Specifications are based on theoretical data. For customized requirements and detailed inquiries, please contact us.

Dimensions

Customized to meet specific project needs.

LSCO Applications

The Lanthanum Strontium Cobalt Oxide Target (LSCO) is versatile and widely utilized in several cutting-edge applications:

- Solid Oxide Fuel Cells (SOFCs): Serves as an efficient cathode material due to its high conductivity and catalytic properties.

- Electronic Devices: Ideal for thin-film deposition in superconductors and magnetic materials.

- Catalysts: Employed in chemical reactions for energy conversion and environmental protection.

- Oxygen Sensors: Provides high stability and excellent electrochemical performance.

- Energy Systems: Enhances the performance of various high-performance electronic and energy applications.

LSCO Packaging

Our LSCO Targets are carefully packaged to ensure their integrity during shipping and storage. Depending on the size, smaller targets are securely housed in polypropylene (PP) boxes, while larger ones are shipped in custom-built wooden crates. We prioritize customized packaging solutions and use appropriate cushioning materials to provide maximum protection.

Packaging Options:

- Carton

- Wooden Box

- Customized Packaging

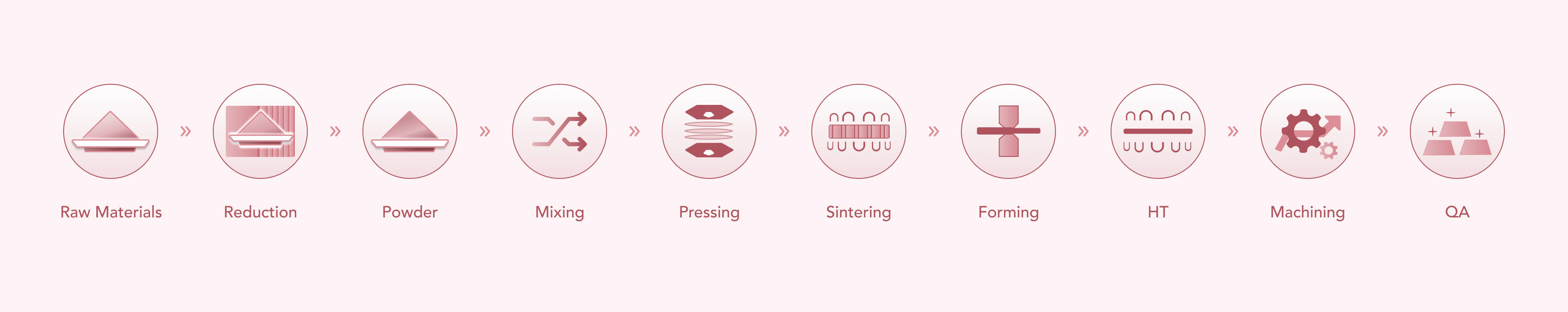

Manufacturing Process

Overview of Manufacturing

Testing Methods

- Chemical Composition Analysis: Verify purity and compositional standards using GDMS or XRF techniques.

- Mechanical Properties Testing: Assess tensile strength, yield strength, and elongation to evaluate material performance.

- Dimensional Inspection: Ensure thickness, width, and length adhere to specified tolerances.

- Surface Quality Inspection: Detect defects such as scratches, cracks, or inclusions through visual and ultrasonic examinations.

- Hardness Testing: Confirm material hardness to ensure uniformity and mechanical reliability.

Frequently Asked Questions

Q1: What deposition techniques are compatible with LSCO Targets?

A1: LSCO Targets are primarily utilized in RF sputtering and DC magnetron sputtering processes for thin film deposition in semiconductor, energy, and electronic applications.

Q2: Is LSCO suitable for applications involving high temperatures?

A2: Absolutely. LSCO demonstrates excellent thermal stability, making it ideal for high-temperature applications like solid oxide fuel cells (SOFCs) and other high-performance electrochemical devices.

Q3: Can LSCO Targets be customized in size and shape?

A3: Yes, Stanford Advanced Materials offers customization options for the size, shape, and backing plate of LSCO Targets to meet specific project requirements.

Performance Comparison: LSCO vs. Competitors

|

Property |

LSCO Target |

ITO (Indium Tin Oxide) |

LaSrMnO₃ (LSMO) |

|

Composition |

La₁₋ₓSrₓCoO₃ (x = 0.1-0.3) |

In₂O₃:Sn (90:10 wt%) |

La₁₋ₓSrₓMnO₃ (x = 0.1-0.3) |

|

Electrical Conductivity |

High (10³-10⁴ S/cm) |

High (10³-10⁴ S/cm) |

High (10³-10⁴ S/cm) |

|

Optical Transparency |

Moderate (80-85% in visible) |

Excellent (>85% in visible) |

Low (<70% in visible) |

|

Thermal Stability |

Excellent (up to 800°C) |

Moderate (degrades above 400°C) |

Excellent (up to 900°C) |

|

Application Suitability |

SOFCs, sensors, TCO sputtering |

Displays, touchscreens, solar cells |

Magnetoresistive devices, sensors |

|

Deposition Compatibility |

RF/DC sputtering, PLD |

Sputtering, evaporation |

Pulsed laser deposition |

|

Key Advantages |

High conductivity, excellent catalytic properties |

Superior optical transparency |

High magnetoresistance |

|

Key Limitations |

Higher cost compared to some alternatives |

Limited thermal stability |

Lower optical transparency |

Additional Information

Raw Materials – Lanthanum (La)

Physical Properties:

- Density: 6.145 g/cm³

- Melting Point: 920 °C (1688 °F)

- Structure: Hexagonal Close-Packed (HCP)

- Magnetic: Paramagnetic

Chemical Properties:

Lanthanum is a soft, silvery-white, ductile rare earth metal commonly found in minerals such as monazite and bastnäsite. It boasts a high melting point and excellent electrical conductivity, forming stable oxide compounds. Lanthanum is pivotal in catalysts, phosphors, and battery technologies, including nickel-metal hydride (NiMH) batteries. Lanthanum oxide is essential for high-temperature applications and solid oxide fuel cells (SOFCs), enhancing device performance and stability.

Industrial Applications:

- Catalysts: Enhances efficiency in chemical reactions.

- Phosphors: Used in lighting and display technologies.

- Battery Technologies: Integral to NiMH batteries.

- Solid Oxide Fuel Cells: Improves performance and stability.

- High-Temperature Applications: Utilized in various industrial processes.

Raw Materials – Strontium (Sr)

Physical Properties:

- Density: 2.534 g/cm³

- Melting Point: 1382 °C (2520 °F)

- Structure: Hexagonal Crystal System

- Magnetic: Paramagnetic

Chemical Properties:

Strontium is a soft, silvery alkaline earth metal found in minerals like celestite and strontianite. It has a relatively low melting point and is highly reactive with water and air. Strontium is primarily used to produce compounds such as strontium carbonate, essential in electronics and ceramics. Additionally, it is used in fireworks for vibrant red flames and in medical applications for bone treatments. Strontium enhances ionic conductivity in ceramic materials, improving the electrochemical performance of solid oxide fuel cells (SOFCs) when incorporated into alloys like LSCO.

Industrial Applications:

- Electronics and Ceramics: Produces durable and high-performance materials.

- Fireworks: Creates bright red flames.

- Medical Treatments: Used in specific bone treatments.

- Energy Systems: Enhances ionic conductivity in fuel cells.

- Chemical Manufacturing: Produces various strontium compounds.

Raw Materials – Cobalt (Co)

Physical Properties:

- Density: 8.90 g/cm³

- Melting Point: 1495 °C (2723 °F)

- Structure: Hexagonal Close-Packed (HCP) at room temperature

- Magnetic: Paramagnetic

Chemical Properties:

Cobalt is a hard, lustrous, silver-gray transition metal with a high melting point and remarkable thermal and chemical stability. It commonly forms +2 and +3 oxidation states and reacts with oxygen, sulfur, and halogens at elevated temperatures. Cobalt is crucial in various industries, including:

Industrial Applications:

- Battery Manufacturing: Essential for lithium-ion battery cathodes.

- Aerospace Alloys: Enhances performance in high-temperature environments.

- Magnetic Alloys: Utilized in data storage devices.

- Catalysis: Acts as a catalyst in hydrogenation and synthetic fuel production.

- Pigments: Produces vibrant blue colors in ceramics and glass.

In Lanthanum Strontium Cobalt Oxide (LSCO), cobalt is vital for its catalytic properties and electrochemical performance, making it indispensable for fuel cells and electronic devices.

- High Purity & Performance 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design 반복 가능하고 균일한 박막 결과를 위해 엄격한 공차로 제조되었습니다.

- Flexible Supply Chain 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.