Different Shapes of Sputtering Targets

(주)연진에스텍은 Planar (flat) Target과 Rotary (cylindrical) Target, Circular Target 및 Ring Target 등 대부분의 증착 공정에 부합하는 다양한 형태의 스퍼터링 타겟을 제공하며, 타겟 크기의 커스터마이즈가 가능합니다.

Li1+xMn2O4 Product Overview

Stanford Advanced Materials (SAM) presents the Lithium-Rich Lithium Manganese Oxide Target (Li₁₊ₓMn₂O₄), a premium sputtering material engineered to boost the capacity and stability of lithium-ion battery cathodes. This target is specifically designed to meet the demands of cutting-edge energy storage applications, offering enhanced performance for advanced battery technologies and thin-film energy solutions.

Li1+xMn2O4 Key Specifications

- Material Composition: Li₁₊ₓMn₂O₄

- Purity: 99.9%

- Shape: Planar Disc

Note: Specifications are based on theoretical data. For tailored requirements and detailed inquiries, please reach out to us.

Detailed Product Description

The Lithium-Rich Lithium Manganese Oxide Target (Li₁₊ₓMn₂O₄) features a spinel crystal structure with an excess of lithium, which significantly enhances both capacity and cycling stability in thin-film applications such as battery cathodes. This compound synergizes the electrochemical activity of manganese with the structural durability provided by its lithium-rich composition, resulting in improved energy density and thermal stability.

Key attributes include:

- Spinel Structure: Facilitates efficient lithium-ion diffusion, crucial for uniform sputtering and thin-film deposition.

- High Lithium Content: Boosts energy density and extends cycle life.

- Chemical Homogeneity: Ensures consistent and reliable thin-film deposition using techniques like pulsed laser deposition (PLD) or RF sputtering.

- Excellent Adhesion: Provides strong bonding to substrates, minimizing defects and enhancing film quality.

- Low Surface Roughness: Ensures smooth thin-film surfaces and controlled grain growth during deposition.

These features make Li₁₊ₓMn₂O₄ an ideal choice for high-performance energy storage devices, including next-generation lithium-ion batteries and advanced thin-film applications.

Li1+xMn2O4 Applications

- Advanced Thin-Film Lithium-Ion Batteries: Utilized as cathode material to achieve high capacity and improved cycling stability.

- Microbatteries: Suitable for powering compact and flexible electronic devices, medical implants, and MEMS technology.

- Solid-State Batteries: Enhances energy density and thermal stability for next-generation energy storage systems.

- Research and Development: Employed in the creation and testing of novel energy materials and advanced cathode chemistries.

Packaging Details

Our Lithium-Rich Lithium Manganese Oxide Targets are carefully packaged to ensure their integrity during transportation and storage. Depending on the size, smaller targets are securely placed in polypropylene (PP) boxes, while larger ones are shipped in custom-designed wooden crates. We prioritize customized packaging solutions and utilize appropriate cushioning materials to provide optimal protection throughout transit.

Packaging Options:

- Carton

- Wooden Crate

- Customized Packaging

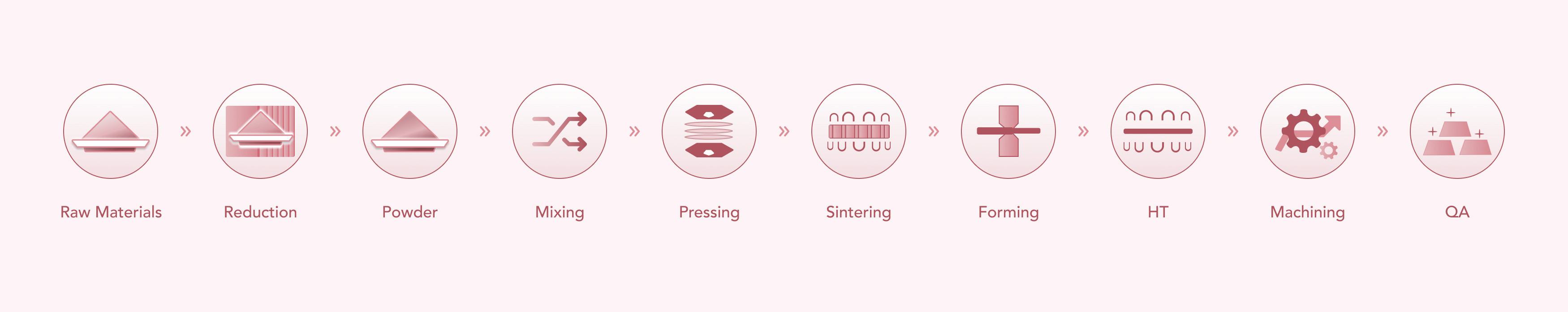

Manufacturing Process

Manufacturing Workflow

Testing Methods

- Chemical Composition Verification: Employ techniques such as Glow Discharge Mass Spectrometry (GDMS) or X-ray Fluorescence (XRF) to ensure the material meets purity and composition standards.

- Mechanical Properties Assessment: Perform tests for tensile strength, yield strength, and elongation to evaluate material performance.

- Dimensional Measurements: Measure thickness, diameter, and other dimensions to ensure compliance with specified tolerances.

- Surface Quality Inspection: Detect defects such as scratches, cracks, or inclusions through visual and ultrasonic examinations.

- Hardness Evaluation: Assess material hardness to ensure uniformity and mechanical reliability.

Frequently Asked Questions

Q1: What are the primary uses of Li₁₊ₓMn₂O₄ targets?

A1: These targets are predominantly used in thin-film deposition for advanced lithium-ion batteries, microbatteries, and solid-state energy storage systems.

Q2: What benefits does Li₁₊ₓMn₂O₄ provide over standard lithium manganese oxide?

A2: The lithium-rich composition enhances energy density, extends cycle life, and improves thermal stability compared to conventional LiMn₂O₄.

Q3: Which deposition methods are compatible with this target?

A3: It is compatible with pulsed laser deposition (PLD), RF magnetron sputtering, and thermal evaporation techniques.

Performance Comparison: Li₁₊ₓMn₂O₄ vs. Competing Materials

|

Property |

Li₁₊ₓMn₂O₄ (x=0.04) |

High-Entropy LiMn₂O₄ (EI-LMO) |

LiMn₂O₄ (Standard) |

LiCoO₂ |

LiFePO₄ |

NMC 811 |

|

Working Voltage (V vs. Li/Li⁺) |

4.0 |

4.0 |

4.0 |

3.8 |

3.4 |

3.6-4.3 |

|

Specific Capacity (mAh/g) |

120-135 (initial) |

120-130 |

110-120 |

140-160 |

150-170 |

180-200 |

|

Cycle Stability (Capacity Retention) |

~85% @50 cycles |

80% @1000 cycles (10C) |

<70% @50 cycles |

~80% @500 cycles |

>95% @500 cycles |

~90% @500 cycles |

|

Li⁺ Diffusion Coefficient (cm²/s) |

~1×10⁻¹⁰ |

~5×10⁻¹⁰ |

~1×10⁻¹¹ |

~1×10⁻¹¹ |

~1×10⁻¹⁴ |

~5×10⁻¹¹ |

|

Crystal Structure |

Spinel |

Spinel |

Spinel |

Layered |

Olivine |

Layered |

|

Cost |

Medium |

Medium-High |

Low |

Very High |

Low |

High |

Raw Materials Information

Lithium (Li)

Lithium is a soft, silvery-white alkali metal with atomic number 3, renowned for being the lightest metal and highly reactive. Its high electrochemical potential makes it indispensable in rechargeable batteries, including lithium-ion and lithium-polymer variants. Additionally, lithium is utilized in advanced ceramics, glass production, aerospace alloys, and nuclear fusion processes. In thin-film and sputtering applications, lithium compounds serve as critical cathode materials for rechargeable batteries.

Manganese (Mn)

Manganese is a transition metal with atomic number 25, belonging to Group 7 of the periodic table. It is a hard, brittle, silver-gray metal typically found in minerals like pyrolusite (MnO₂). Manganese enhances the hardness, stiffness, and strength of steel and other alloys, making it essential in steel production. It is also widely used in battery manufacturing, ceramics, fertilizers, and electronic materials. In advanced materials and thin films, manganese is a key component in magnetic and oxide compounds, such as Lanthanum Strontium Manganite (LSMO), which is utilized in spintronics, magnetic sensors, and memory devices due to its colossal magnetoresistance and other functional properties.

- High Purity & Performance 일관된 증착 품질과 오염을 줄이도록 가공합니다.

- Material Variety 다양한 응용 분야의 요구 사항에 맞게 순수 금속, 합금, 세라믹 및 화합물로 제공됩니다.

- Custom Manufacturing 특정 시스템의 필요요구 사항에 맞게 크기와 형태, 조성을 맞춤화했습니다.

- Precision Design 반복 가능하고 균일한 박막 결과를 위해 엄격한 공차로 제조되었습니다.

- Flexible Supply Chain 최고의 제조업체와 강력한 파트너십을 통해 일관된 품질과 on-time 납품을 보장합니다.