Written by Korvus Technology

Published on

What Is PVD Coating? Physical Vapour Deposition Explained

The need for high-performance thin-film coatings is higher today than ever, and many industries have turned to physical vapour deposition (PVD) as their coating method of choice. PVD is the gold standard for generating extremely thin, pure, and durable coatings from a wide array of target materials and substrates to coat everything from optics to computer chips.

What Is the PVD Coating Process?

PVD coating, also known as thin-film coating, uses a vacuum chamber to vaporise a solid material and deposit it onto a target substrate, atom by atom. The result is an extremely thin, extremely pure coating from a technique that is more environmentally friendly than many other coating technologies[1].

The PVD coating process occurs under vacuum conditions and consists of four main steps: ablation, transport, reaction, and deposition. This process deposits source atoms onto the surface of the substrate, leaving it coated with a strong, abrasion- and corrosion-resistant film.

Evaporation

The two main types of physical vapour deposition are Sputtering and Thermal Deposition.

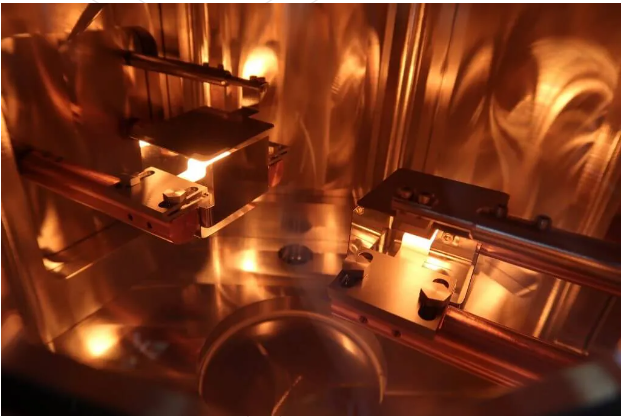

Thermal evaporation deposition uses vacuum pressures and high temperatures to create the conditions necessary for the vaporisation of the target material.

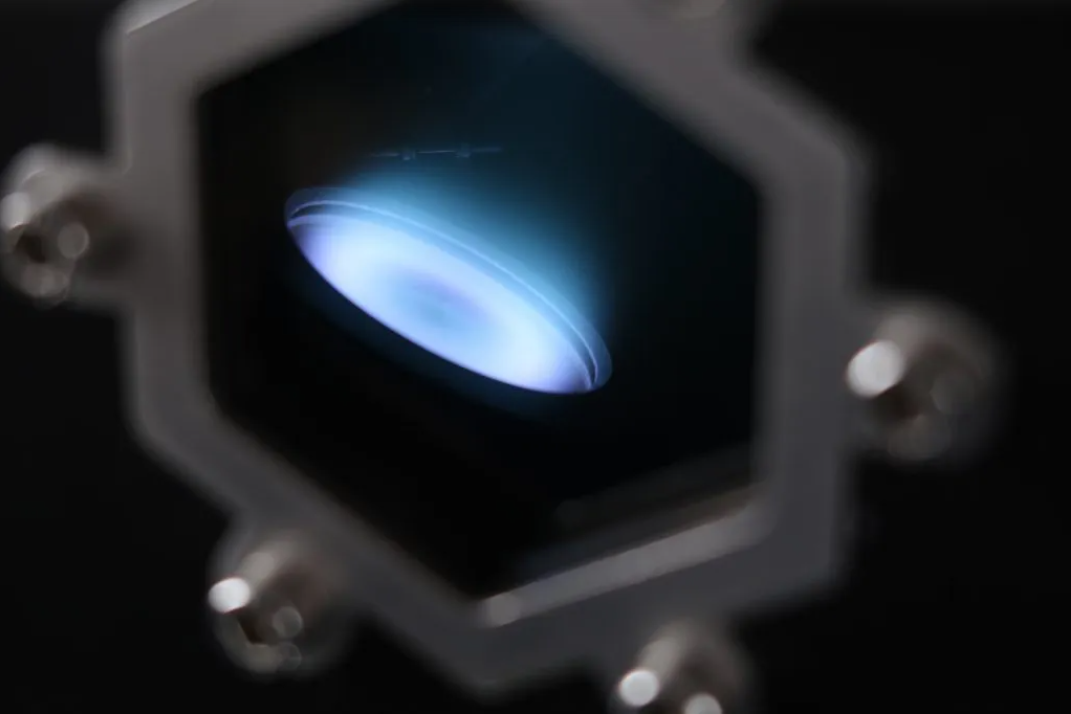

Sputtering uses a high-vacuum chamber that dislodges atoms from the target using high-energy plasmas. These atoms are then ready for deposit onto the target surface, usually in a plasma arc.

This process biases the target before bombarding it with ionised gas in a vacuum environment. This ionic bombardment results in atoms “sputtering” off the target into a plasma cloud arc before transport and condensation.

Both processes have unique advantages and disadvantages that make them useful for different applications. Sputtering produces a highly uniform coating with low impurity rates, but it is also the slowest and most complex method. Thermal evaporation has higher throughput and high mineral utilisation efficiency but may require additional tools to achieve good uniformity during the process, such as sample rotation[2].

Transportation

The movement of vaporised atoms from the target material to the substrate requires precise timing and positioning. The correct PVD method for the material is important as well as the geometry of the system and deposition source in relation to the sample holder.

Reaction

PVD processes can use reactive or inert gases to produce a strong bond between the coating and the substrate for the best possible results. For example, oxygen and nitrogen are common gases used for reactive RF sputtering with metal oxides and nitrides.

Deposition

The final step of the process builds up the coating on the required substrate. Since the thin-film can be anywhere from a few atoms thick up to a few microns, a uniform deposition across the substrate is important. The PVD process involves rotating the substrate at a constant speed while monitoring the rate of deposition with other tools such as a quartz crystal microbalance.

Many industrial methodologies can automate the deposition process by putting a conveyor belt of targets in front of the vaporised arc for a certain length of time. Both sputtering and evaporation can use automation to speed up the PVD coating technique for mass production.

Safety, Properties, and Advantages of PVD Coatings

Advantages of PVD Coatings

Safer than Plating

PVD coating is an alternative to traditional metal coating processes, where a thin layer of metal coats a substrate. In industry, metal coating processes use either an electric current (electroplating) or an autocatalytic process (electroless plating) to achieve a strong bond between the substrate and metal. However, many traditional coating processes also produce potentially harmful waste products, and some processes such as cadmium coating are decreasing in popularity due to safety concerns[3].

PVD coating requires no compounds other than the substrate and target material, resulting in a more environmentally friendly, safe process that caters to a wide range of industries and applications.

Highly Durable

PVD coatings tend to have highly robust temperature tolerance and impact strength along with excellent abrasion and corrosion resistance[4].

Versatile

Unlike metal plating, PVD is suitable for almost any inorganic coating material over a massive range of substrates. Manufacturers can use different PVD technology to generate a wide range of finishes ideal for almost any application or part.

Is PVD Coating Food-Safe?

PVD coatings vary dramatically in their chemical properties, but most adhere strongly to their substrate once applied and are often chemically and biologically inert. One of PVD’s most prominent industries is the cutlery industry for both decorative and functional applications, including commercial kitchen equipment.

Most PVD finishes are food-safe and provide wear-resistant coatings that can withstand significant wear and tear[5].

PVD Applications Across Industries

PVD’s versatility in materials, finish, and composition makes it an appealing coating choice for a vast array of industries. Wherever you find a coated material, you’ll likely find a PVD process behind it.

Microelectronics

Electronics like phones, circuits, and optical discs have a thin film deposited on them for conductivity and durability. Some films can act like superconductors and enhance the performance of electronic semiconductor devices.

Home Hardware

Many home fixtures, including taps, sinks, showerheads, window dressings, and drawer handles, use a vacuum coating of various materials, including nickel, stainless steel, copper, bronze, and even black PVD coatings.

PVD coatings are also commonly used in interior fixtures such as valves that experience high wear and tear. When coated with robust materials, these fittings can last significantly longer than with traditional chemical coating methods.

Automotive Applications

Many automotive parts use chrome as a decorative and functional coating, including interior trim, engine components, and even headlamps. PVD coatings allow for a more durable product that uses cleaner technology with PVD coating equipment instead of messy tanks of electrolytes.

PVD coating stainless steel creates less friction and higher temperature tolerances, essential to getting the best performance out of engine components. Plastic headlights contain a thin metal coating of aluminium to create a mirror to reflect the light generated from the LED bulb.

Food Packaging

Aluminium is an often-used preservative in the food industry, but the hardness and rigidity make it unsuitable for some packing applications. Aluminium-coated plastic is a common package for crisps and other snack foods to keep them fresher for longer.

Another application is to embed silver in existing PET plastics to prevent microbial growth[6]. This method will ensure that the plastic retains its bulk properties while providing food safety advantages.

Optics

Modern eyewear uses plastic lenses that are more durable than their glass counterparts but are more prone to scratching and discolouration. A PVD coating retains the hardness and versatility of plastic while adding an anti-reflective or scratch-resistant layer for maximum durability.

Several car manufacturers also use a PVD coating machine to tint car windows or apply a UV-resistant film. This film ensures that drivers still get maximum visibility due to the finish of the product while getting the benefits of UV protection and privacy.

PVD coating are also implemented in research of future photovoltaic applications and other transparent conducting oxide applications.

Medicine

PVD films are essential components in the medical field, with an extensive range of applications. A popular PVD coating, titanium nitride, is a standard coating on prosthetics, whose metals the host body often rejects due to interaction with biological liquids. It’s also useful as a surface coating for scalpels as it helps blades retain their sharpness longer.

Chromium nitride is a standard thin film for orthopaedic and dental instruments requiring regular sterilisation with high-pressure, high-temperature autoclaves. The film protects the tool’s surface from wear and corrosion, leading to improved performance and cost-effectiveness of the tools.

Home Tools

Many stainless steel home tools have coatings to keep their edges sharper for longer. Some of the most common finishes and PVD films include titanium nitride and diamond-like coatings that are significantly harder than steel. These films keep drill bits and other tools sharper, which is essential for high-pressure applications.

Decorative Applications

PVD is appealing for decorative use due to its variety and range of both colours and finishes, as well as its versatility in materials. These include copper PVD coating, nickel or chrome coatings, or even ceramic films.

Compared to traditional methods of metal finishing, PVD increases hardness and resistance to tarnishing and fading. A designer can limit its application to one part or use it on multiple components. Common usages are knives and blades, fittings, and even jewellery.

What Are the Most Common PVD Coating Target Materials?

Evaporative and sputtered PVD coatings are suitable for almost any inorganic solid material and almost any target surface. Materials with a high melting and vaporisation temperature will do better with sputtering in the vacuum chamber instead of evaporation techniques. However, there is a process suitable for almost any material or product on the market.

Some common materials for sputtering films include:

- Cr2N: A beautiful silver film used to PVD-coat external parts of watches or jewellery

- TiN: One of the most-used sputtering films, useful in decorating phones, glasses, hardware parts, and sanitary ware

- ZnSn: An optical PVD coating that reflects light, leading to its use in low-e windows and glass

- AlCr: A sputtering film that extends the service life of equipment like tools and machine parts

- ITO thin film: A high-conductivity, high-mechanical-hardness film useful for LCDs, plasma displays, and touch panels

Different industries will have varying requirements for their PVD material films, with distinct coatings suitable to those requirements. However, some popular compounds make it into a huge range of industries due to their well-documented, universally useful properties.

Conclusion

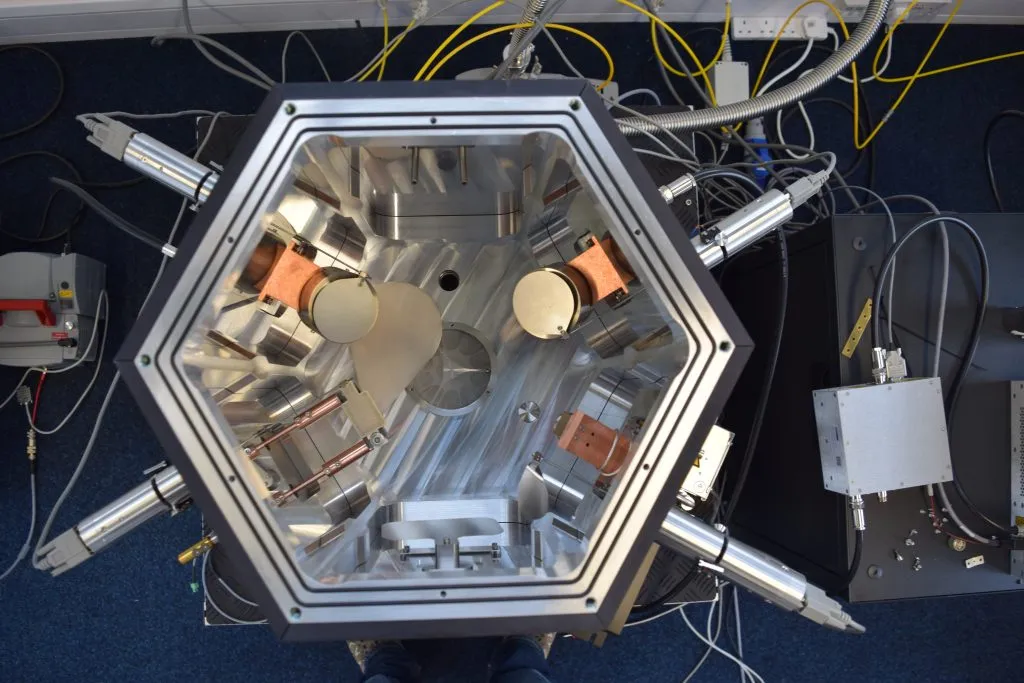

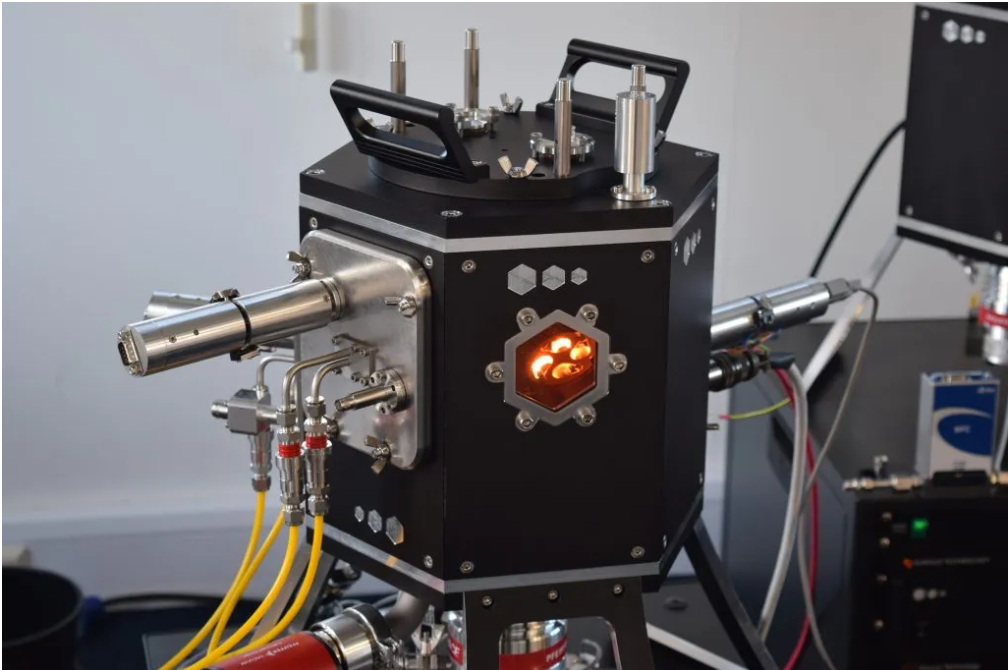

Korvus Technology is a leading materials science research and development company in the UK with extensive industrial experience in thin-film technology and high-vacuum PVD coatings. We manufacture the HEX Series, a thin film deposition system that provides support for a variety of techniques, depending on your requirements.

Interested in learning more? We’d be happy to speak with you and understand your project and how our HEX system can help.

References

[1] P. De Araujo, P. Steyer, J.-P. Millet, E. Damond, B. Stauder & P. Jacquot (2003). PVD Aluminium Alloy Coatings: Environmentally Friendly Alternative to Protect Steel Parts Against Corrosion, Surface Engineering, 19:4, 304-309, DOI: 10.1179/026708403322499245

[2] O. Kahveci, A. Akkaya, E. Ayyildiz & A. Turut (2017). Comparison of the Ti/n-GaAs Schottky Contact’s Parameters Fabricated Using DC Megatron Sputtering and Thermal Evaporation. Surface Review and Letters 04:24. DOI: 10.1142/S0218625X17500470

[3] World Health Organization. Exposure to Cadmium: A Major Public Health Concern. https://apps.who.int/iris/bitstream/handle/10665/329480/WHO-CED-PHE-EPE-19.4.3-eng.pdf, Accessed 03 February 2022.

[4] J. Smolik, M. Gulde, J. Walkowicz & J. Suchanek (2004). Influence of the structure of the composite: ‘nitrided layer/PVD coating’ on the durability of forging dies made of steel DIN-1.2367. Surface and Coatings Technology 180-181, 506-511. DOI: 10.1016/j.surfcoat.2003.10.152

[5] P.Eh. Hovsepian, W.-D. Münz, A. Medlock, & G. Gregory (2000). Combined cathodic arc/unbalanced magnetron grown CrN/NbN superlattice coatings for applications in the cutlery industry. Surface and Coatings Technology 133-134, 508-516. DOI: 10.1016/S0257-8972(00)00921-X

[6] M. Benelmekki, M. Torrell, E. Xuriguera, F. Vaz, & V. Teixeira (2012). Structure and Properties of Silver Clustered Implanted in PET by PVD Stuttering for Active Packaging Applications. Journal of Nano Research 18-19, 105-116. DOI: 10.4028/www.scientific.net/JNanoR.18-19.105