Written by Korvus Technology

Published on

Thin Film Deposition Techniques and Systems

Thin films are an inseparable part of modern technology. When deposited on the surface of an object, thin film coatings can alter its qualities, for example, increasing durability, changing electric conductivity, or improving optical properties.

But how do we define a ‘thin film’? A thin film is a layer of material ranging in thickness from sub-nanometres to microns. A few popular examples of thin film deposition techniques are physical vapour deposition (PVD), chemical vapour deposition (CVD) and atomic layer deposition (ALD).

The history of thin solid films begins in antiquity [1], with metallic films (usually gold platings) used on various artefacts for decorative and protective purposes. Today, many industries rely on precise atomic layer deposition (ALD) to produce high-purity thin films.

Industrial applications include thin film solar cells, optical lenses with a high refractive index, anti-reflective optical coatings, semiconductor devices, light crystal displays, and more.

In this article, you’ll find out more about thin films and the thin film deposition process.

What is Thin Film Deposition?

The thin film deposition process may vary depending on the techniques used, but all the methods we will discuss here involve placing a thin layer of deposited film on the substrate surface within a vacuum chamber.

The first creation of metal films by chemical vapour deposition took place in the mid-17th century. Experiments in oxide deposition began circa 1760, while sputter deposition took its first steps in the 1850s [2].

By the 1930s, manufacturers already used early-stage thin films for high-reflectivity mirrors. The 1960s technologies of ultra-high vacuum and in situ electron microscopy enabled the creation of more advanced, pure, and uniform thin films. In 1970, Peter J. Clarke launched the first sputter gun that created atomic-scale films by using ion and electron collisions.

Advanced technologies, such as atomic resolution surface imaging, allowed the progress of the thin film industry as we know it today. Methods for depositing thin films, such as sputtering-based methods, continue to grow and develop into new applications.

Physical vapour deposition (PVD), which involves the vaporisation and depositing of solid material on a substrate, encompasses a range of methods from a basic evaporation process to magnetron sputtering and pulsed laser deposition [3].

Many advanced thin-film devices, like the HEX Series by Korvus Technology, use physical deposition methods. PVD, in particular sputtering systems, allow manufacturers to create highly precise and uniform thin films.

In contrast, chemical vapour deposition relies on a reaction between precursors in the deposition chamber. CVD has several common uses, like creating Si thin films. A potential drawback of CVD however, is the need for extra-high temperatures to incite the process.

The Different Thin Film Deposition Techniques: Physical Vapour Deposition and Chemical Vapour Deposition

Deposition techniques fall into two main groups: physical vapour deposition and chemical deposition. Physical Vapour Deposition (PVD) and Chemical Vapour Deposition (CVD) differ fundamentally in their deposition methods. PVD involves the physical transfer of materials under vacuum, where vaporised materials condense onto the substrate, making it ideal for metals and alloys. In contrast, CVD utilises chemical reactions at elevated temperatures to deposit materials from a vapour phase, suitable for complex compounds and polymers. PVD offers precise control over thickness and purity, whereas CVD excels in achieving uniform coatings over intricate shapes. The choice between PVD and CVD depends on the required material properties and the specific demands of the application.

See more: PVD vs CVD

Physical Vapour Deposition Methods

There are a wide range of thin film deposition techniques and choosing the best deposition method for you will depend on numerous factors. Things to bear in mind as you make your decision are:

- The target material

- The substrate

- The required deposition rate

- Your application

- Budget available

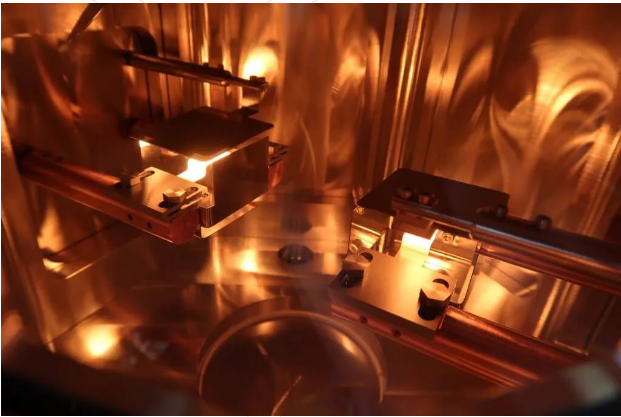

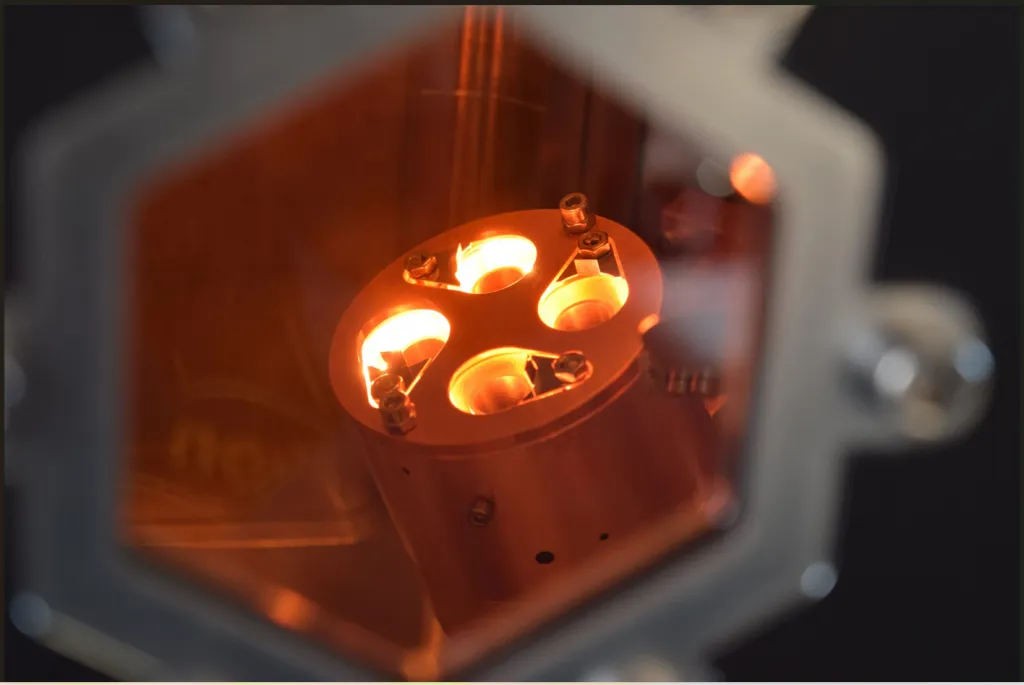

At Korvus Technology, the HEX Series is a physical vapour deposition coating system, covering a range of techniques which we will explore below.

Thermal Evaporation

Thermal evaporation deposition occurs in a chamber under the pressure of 10(-7) to 10(-5) mbar. A crucible that connects to a high-current source holds the target material.

Here are the basic steps for thermal evaporation deposition:

- A current is applied to the source and the material in the crucible is resistively heated. This will eventually vaporise the material and release the vapour into the chamber.

- The vapour stream then crosses the chamber and coating particles attach to the substrate generating a thin film of the evaporated material.

- Throughout the process, the vacuum pump keeps working to maintain a high-vacuum environment and ensure a free path for the film particles.

Magnetron Sputtering

Sputtering is a physical phenomenon leveraged by thin film deposition to expel microscopic particles of solid materials from their surface. This ejection is achieved by attacking the solid material with energetic particles. The particles are then deposited in the target materials forming the thin film layer.

Like other deposition methods, sputtering takes place in a chamber with a vacuum pump constantly working to remove air. The vacuum is a crucial condition for this process, which occurs naturally in outer space.

Magnetron sputtering involves the following steps:

- An inert gas, usually argon, flows continuously into the chamber. Magnet arrays within the vacuum chamber generate a magnetic field.

- The high voltage creates a gaseous plasma near the target’s magnetic field. The plasma contains argon gas atoms, argon ions, and free electrons. Electrons that hit argon atoms continuously create more positively charged ions.

- The negatively charged sputtering target attracts the positively charged ions. As the ions hit the target, they eject atoms through a process called ion bombardment.

- The ejected atoms settle on the substrate’s surface and create a thin film of the target used on the magnetron.

Electron Beam Evaporation

Electron beam evaporation is a process where a focused electron beam vaporises a target material, causing it to condense and deposit material onto a substrate. This technique is preferred over thermal evaporation due to its precise control over the deposition rate and film thickness. It is particularly beneficial for materials with high melting points, ensuring the deposited material maintains purity and quality without substrate contamination. Thus, electron beam evaporation is selected for its superior efficiency and effectiveness in producing high-quality thin films.

Learn More About Electron Beam Evaporation

Low-Temperature Organic Evaporation

Organic evaporation involves heating organic materials until they vaporise, allowing the material to be deposited onto a substrate, but having a precise control of temperature due to the nature of many organic substances. This method is particularly suited for organic compounds that are sensitive to high temperatures or electron beam exposure. Low-temperature evaporation is chosen for its ability to gently deposit thin films of organic materials, such as polymers and organic semiconductors, without altering their chemical structure. It ensures the integrity of the material to be deposited, making it ideal for applications in organic electronics and bio-compatible coatings.

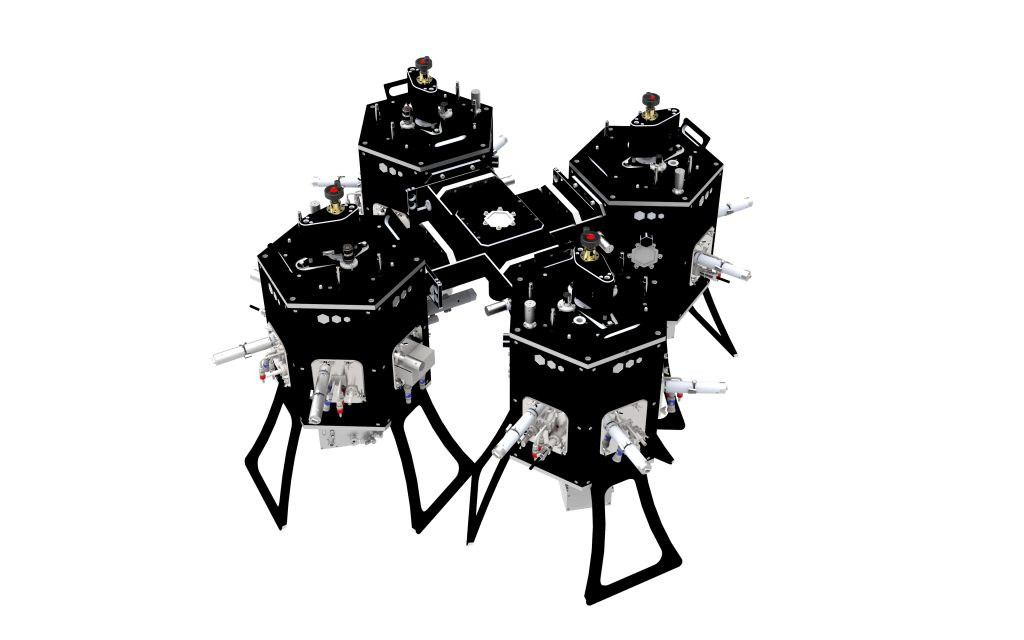

Meet The HEX: A Modular Thin Film Deposition System

The HEX Series offers a flexible array of thin film deposition systems tailored for both research and practical applications. Initially, you can acquire the basic model and progressively enhance it with advanced components based on your desired film thickness, materials and other requirements. This makes it suitable for many applications. These components are designed for easy integration, minimising both the downtime of the system and the cost of installation.

This series is comprised of the compact HEX model and the more spacious HEX-L and HEX-XL Systems.

See more:

Types of Thin Film Coatings and What They’re Used For

Thin films are coatings deposited upon a substrate material (like a silicon wafer, electronic part, or optical lens). Depending on the material and purpose, the film thickness can be anything from one atomic layer to several micrometres.

Different applications will call for distinct types of thin films. These include:

- AR/HR (antireflective or high-reflectivity) coatings alter the optical properties of a material, for example by filtering visible light or deflecting a light beam. Common uses for these thin films include electronic displays, low optical thickness lenses, and output mirrors.

- TCO (transparent conductive oxide) coatings are electrically conductive, transparent coatings with many uses in touchscreens, LCDs, and photovoltaics. One example is hydrogenated microcrystalline silicon-germanium thin films in solar cells.

- DLC (diamond-like carbon) thin films increase the coated object’s hardness and scratch resistance. These electrically resistive protective coatings improve the lifespan and durability of microelectronics, medical devices, sensors, and more.

- Biocompatible hard coatings protect implanted devices, biosensors, and artificial limbs to improve the devices’ longevity and prevent contamination. Biocompatible thin films typically use compounds like titanium nitride and chrome nitride.

In this article, we discuss two main deposition techniques: physical vapour deposition (PVD) and chemical vapour deposition (CVD). These methods have shown significant advantages over other techniques, like dip or spin coating, in most applications.

Physical vapour deposition involves vaporising materials in a low-pressure chamber to deposit them upon a substrate. Films deposited by PVD can create highly durable, corrosion-resistant coatings that tolerate exposure to high temperatures.

Chemical vapour deposition typically involves chemical reactions between precursors, which combine to create a thin film coating on the substrate surface. CVD may involve several advanced techniques, such as reactive ion etching.

How PVD is Used to Create Thin Films in The Industry

As we’ve discovered, thin film processes have applications in various fields and form the cornerstone of many industries today. Thin films are used in semiconductors, medical devices, fibre lasers, LED displays and much more.

Here are just a few examples of advanced applications of thin film technology:

- Solar cells. A thin film solar cell owes its energy generation properties to the layer of silicon thin film (also known as “Si Thin Films”) deposited on a glass or metal substrate. Second-generation Si thin film solar cells are flexible and lighter than crystalline silicon cells, which enables applications like photovoltaic glazing [4]. Amorphous silicon, a non-crystalline form of silicon, is an affordable substrate that helps reduce the cost and scale the production of thin film panels.

Read more about thin film solar cells - Thin film transistors. Thin film transistors are a vital component of liquid crystal displays. This type of transistor is inexpensive, energy-efficient, and offers better response time.

Read more about thin film transistors - Thin film batteries. A thin film battery is more efficient, charges faster, and lasts longer compared to a conventional Li-ion battery. This type of battery can improve the performance of medical products, implants, smart cards, and green energy storage banks.

Read more about thin film batteries

The thin-film industry keeps evolving. Researchers never stop looking for ways to improve the purity, accuracy, optical properties, and other qualities of thin films. Meanwhile, industry experts work towards reducing costs and overcoming scaling obstacles in thin film production.

To implement thin film deposition in your production chain, you’ll need to deploy a thin film deposition system.

Learn More: The HEX Series Cluster Systems

Korvus Technology is a reliable provider of modular deposition systems and other thin-film accessories and components for laboratories and manufacturers.

Thin Film Deposition Technologies: Final Words

The world as we know it today relies on thin films. Thin films are everywhere, from a bag of crisps to the device you are using to read this article.

Often invisible, thin films are the quiet superheroes of modern industry, with a range of uses from prolonging shelf life to improving optical properties of lenses. Thin films may consist of metals, oxides, and organic materials.

The technologies for making thin films vary depending on the application and industry demands. If you are interested in learning more about thin films, we invite you to browse other articles at Korvus Technology.

References

[1] Greene, J.E. Review article: Tracing the 5000-year recorded history of inorganic thin films from ∼3000 BC to the early 1900s AD. Applied Physics Reviews, Volume 1, Issue 4, 22 July 2014.

[2] Greene, J. E. Review Article: Tracing the recorded history of thin-film sputter deposition: From the 1800s to 2017. Journal of Vacuum Science & Technology, Volume 35, Issue 5, 10 May 2017.

[3] Baptista, A., et al. On the Physical Vapour Deposition (PVD): Evolution of Magnetron Sputtering Processes for Industrial Applications. Procedia Manufacturing, Volume 17, 2018, Pages 746-757.

[4] Luceño-Sánchez, J.A., et al. Materials for Photovoltaics: State of Art and Recent Developments. International Journal of Molecular Sciences. Volume 20, Issue 4, 23 February 2019.