Written by Korvus Technology

Published on

The many applications of vacuum deposition processes span industries. Manufacturers use vapour deposition in solar cells, medical implants, LED displays, and other products.

Manufacturers and researchers use one of two types of thin film deposition: physical vapour deposition (PVD) and chemical vapour deposition (CVD). Between PVD and CVD, your ideal system will depend on your substrates and application needs, including performance at a high temperature.

Below, we explore PVD vs CVD by explaining both techniques and presenting the advantages of each to help you choose your ideal system.

What Is Physical Vapour Deposition?

Physical vapour deposition takes a solid precursor material and turns it into a gas in a reacting chamber, where the atoms deposit a thin film onto a substrate through condensation. Most PVD coating applications use the following techniques:

Evaporation

Thermal evaporation vaporises a coating material, turning it into a gas. The released atoms enter a reaction chamber and coat the surface of a substrate material in a very thin layer.

Sputtering

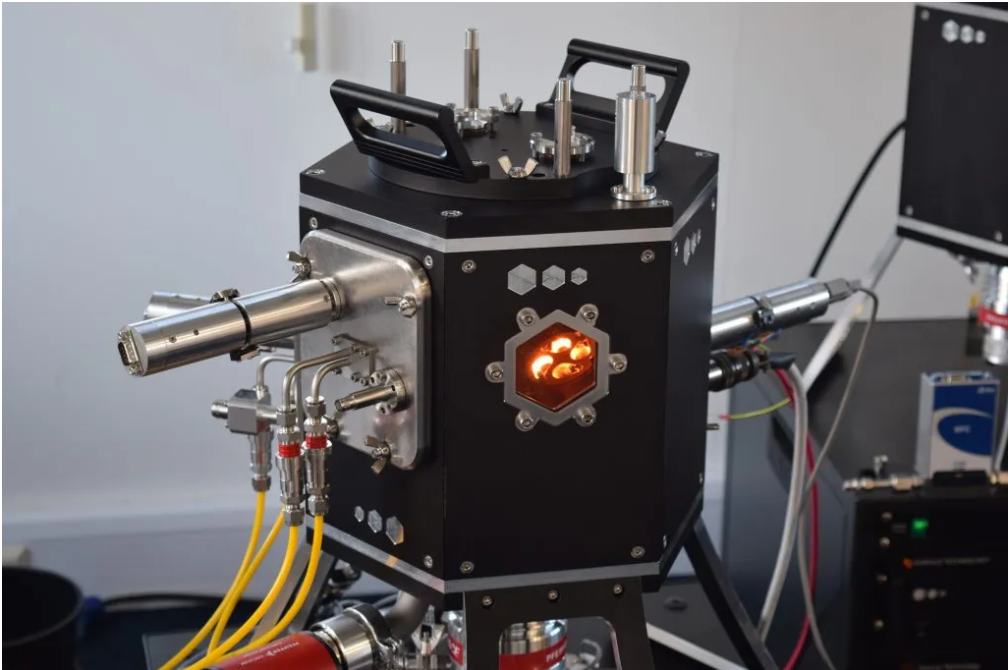

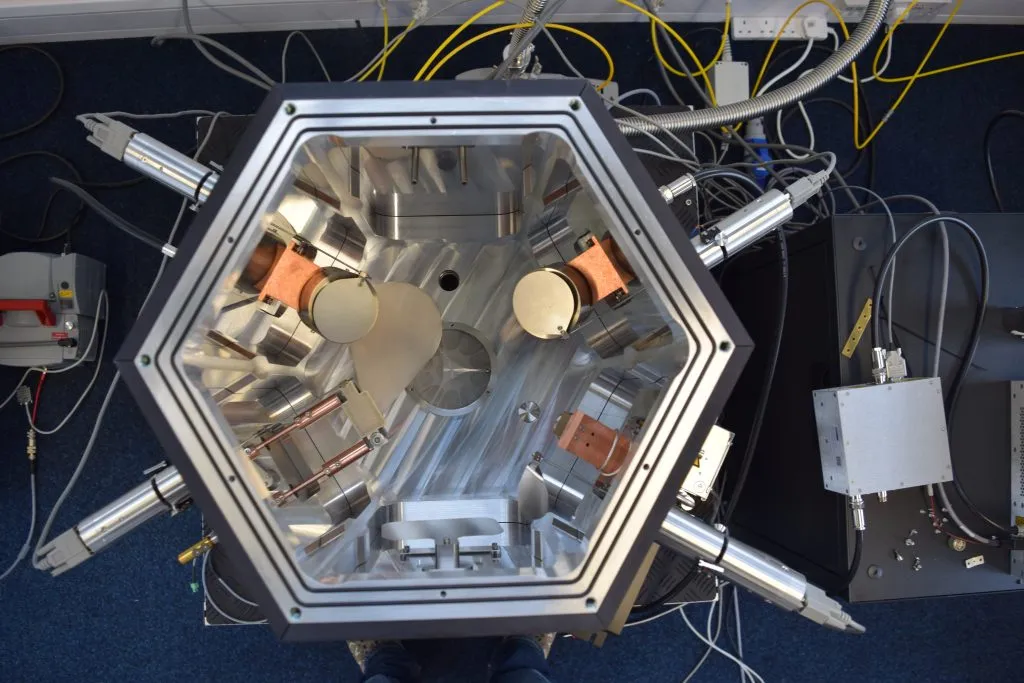

The sputtering process uses plasma ions moving at high speeds to release atoms from the source material. The atoms in the reaction chamber stick to the target substrate. Korvus Technology’s HEX Series thin film deposition system supports several techniques, including sputtering.

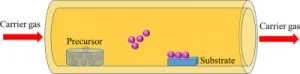

What is Chemical Vapour Deposition?

Chemical vapour deposition is similar to PVD, but the difference is that CVD uses volatile precursors to deposit a gaseous source material onto the substrate’s surface. Chemical reactions initiated through heat or pressure cause the coating material to form a thin film on the substrate in the reacting chamber.

What Is the Difference Between PVD and CVD?

While both processes create thin films over substrate materials, PVD and CVD coating techniques differ in several ways:

Process

The coating process is the main difference between PVD and CVD. Physical vapour deposition uses physical reactions to change a liquid source material to a gas. The material then returns to its solid state as a thin layer on the surface of the substrate.

Chemical vapour deposition creates thin films using chemical reactions. The polymerisation and coating phases occur at the same time, which creates copolymers of different monomers for a broad range of applications [1].

PVD and CVD coating processes also differ in how well they coat the substrate. PVD does not perform as well on the sides and back of the coating substrate, whereas CVD techniques produce a uniform thin coat on uneven surfaces.

Temperature

PVD deposition occurs at a relatively low temperature, up to 450 degrees Celsius. CVD deposition requires higher temperatures above 900 degrees Celsius [2]. Due to the high temperatures, the CVD process often includes heat treatment of the coated surface.

Application

PVD can improve a substrate’s tolerance to high temperatures and ablation, ideal for glass and decorative coatings, diffusion barriers, and aerospace technology.

The high-temperature CVD process creates thin films with superior purity and uniformity. Applications include protective layers, semiconductors, and more [1].

What Are the Advantages of CVD Over PVD?

Chemical vapour deposition provides a versatile process for coating the surface of a substrate. When considering PVD vs CVD, keep in mind these advantages of the CVD method:

- High purity: Many manufacturers prefer CVD for coating materials that require specialised thin films at an exact desired thickness. CVD uses gas coating materials, avoiding the impurities of liquid coating processes.

- Uniform coating: CVD is a conformal deposition process, which means it uniformly coats a substrate regardless of the shape to produce an even coating. This method builds the desired layer from the substrate up, a significant advantage in creating conductive films [1].

- Application variety: Manufacturers use CVD to create thin layers on many materials regardless of rigidity, flexibility, or density [1]. You’ll find CVD systems across industries, from electronics manufacturing to producing crisp bags. CVD can produce large graphene sheets, carbon nanotube arrays, and other essential coated manufacturing materials [3].

- Cost: CVD systems cost less than PVD systems.

The possibilities of the CVD method continue to expand into new applications.

What Are the Advantages of PVD Over CVD?

Physical vapour deposition is an often-used method for coating inorganic materials, such as metal and some organic materials. It offers many advantages, including the following:

- Temperature resistance: PVD films can withstand temperatures over 400 degrees Celcius, making them ideal in the manufacturing of high-performance solar power technology and other applications that require resistance to intense heating [4].

- Abrasion and impact resistance: PVD techniques can create a very thin layer of only 2.5 micrometres that provides superior resistance to abrasions.

- Environmental friendliness: Unlike CVD, PVD does not produce hazardous byproducts and does not use hazardous gases in its processes. Instead of using a reactive gas, PVD uses high-power electricity or lasers to gasify the coating material.

- Wear-resistant coating: Manufacturers use PVD for many coating applications, including improving wear resistance and reducing the friction of cutting tools, and creating anisotropic glasses for semiconductors. You’ll see examples of PVD use across industries, including architecture, automotive, jewellery, and more.

When comparing PVD and CVD costs, PVD tends to cost more than CVD, but many manufacturers consider PVD best for their applications.

Conclusion – PVD vs CVD Coating

To summarise, PVD and CVD both function as methods of binding the desired layer to a substrate material. The primary difference is that PVD uses a liquid source material to create a thin film, while CVD uses a gaseous source material.

PVD and CVD suit different applications, depending on purity, speed, and cost requirements. You may choose a CVD system to form graphene sheets for electronics, or you may select a PVD system for metal coating with plasma ions for solar panels.

If you’re looking for a compact, high-performance PVD system, Korvus’ HEX series modular PVD system supports sputtering, thermal evaporation, sample preparation, pulsed laser deposition, and organic PVD thin film deposition.

Every vapour deposition application comes with different requirements, and we can provide a custom solution that meets your needs. The versatile HEX series provides the perfect system to teach thin film methodology, research new coatings, or deposit thin films through benchtop production.

References

[1] Asatekin, A., Barr, M. C., Baxamusa, S. H., Lau, K. K. S., Tenhaeff, W., Xu, J., & Gleason, K. K. (2010). Designing polymer surfaces via vapor deposition. Materials Today, 13:5, 26–33. https://doi.org/10.1016/s1369-7021(10)70081-x

[2] Musbah, A., & Eljaafari, W., Fessatwi, E., & Elsahli, Y. (2022). Comparison Between Chemical Vapor Deposition CVD and Physical Vapor Deposition PVD Coating Techniques: A Review Paper. February 2022.

[3] David L. Chandler. Explained: Chemical vapor deposition. MIT News | Massachusetts Institute of Technology. https://news.mit.edu/2015/explained-chemical-vapor-deposition-0619. Accessed 02 November 2022.

[4] Selvakumar, N., & Barshilia, H. C. (2012). Review of physical vapor deposited (PVD) spectrally selective coatings for mid- and high-temperature solar thermal applications. Solar Energy Materials and Solar Cells, 98, 1–23. https://doi.org/10.1016/j.solmat.2011.10.028