보유장비 (R&D Facility)

플라스틱 품질 및 정성 분석기 - Plastic Identification, Confirmation, and Comparison

고분자 제조 및 가공, 재가공 중 플라스틱의 품질(quality)과 식별(identification) 분석

유리전이온도(Glass Transition Tg, °C)와 용융점(Melting Point Tm, °C)을 측정하는 DSC 겸, 동시에 Tangent Delta, Stiffness (N/m), Molding displacement를 측정하는 DMA 역할을 합니다. 플라스틱 원료 입고 시 플라스틱의 빠른 정성 분석 뿐만 아니라, 특정한 플라스틱의 가용 여부를 확인하여, 기준 재료와 새로운 재료의 비교가 가능합니다.

열가소성 수지의 품질을 식별하고 평가할 수 있습니다.

원료의 식별 (identification)과 확인 (confirmation), 비교 (comparison), MFi

과립, 플레이크, 분말 또는 완성된 몰딩에서 채취된 일부 조각까지 어떤 플라스틱이라도 분석이 가능합니다.

Identification

기본 열가소성 플라스틱 라이브러리로 부터 플라스틱 재료의 유형을 식별합니다. 이 모드를 사용하면 재료를 LDPE, HDPE, PP, PA6 PA66 등과 같은 고분자를 간단히 식별할 수 있습니다. 펠릿, 입자상 또는 분말 형태의 고분자 샘플은 QA2 장치 내에서 몰딩, 측정, 식별되며, 식별과정을 통과한 플라스틱은 목표하는 일관된 생산이 가능하도록 해줍니다.

Confirmation

샘플이 알려진 기준 재료 (reference)와 충분히 유사한 지 확인하여 이에 대한 확신을 가지고 플라스틱 생산 라인에서 사용할 수 있으며 가공된 제품의 지속적인 품질을 보증합니다. 바이어를 위한 상세한 적합성 인증서(certificate of conformanc)가 생성됩니다.

Comparison

두가지 등급의 재료가 동등한 지 비교하고 얼마나 유사한 지 비교할 수 있습니다. 비교 모드(Comparison mode)는 호모 폴리머(homopolymer)를 코 폴리머(copolymer)와 비교하고 다른 제조업체 또는 공급 업체의 원료를 비교할 수 있습니다.

What can the identiPol do for you?

Save time

• 생산에 들어가는 그릇된 재료와 그로 인한 문제 방지

• 재료 품질 보증과 관련하여 공장에서 신속하게 "Go / No Go"를 결정

• 생산이 최대 효율로 가동되는지 확인

Save money

• 낭비 리스크 감소

• 제품의 품질을 유지하면서 저렴한 공급 업체로 변경

• 잠재적으로 보험료 감소

Secure your reputation

• 불량품이 고객에게 전달되는 것을 사전에 방지

• 고객에게 추적 가능한 재료 적합성(traceable material conformance) 제공

• 생산 제품의 품질에 대한 컴플레인 디펜스

Specifications

|

Sample size |

20-30mg (one or two plastic granules, plastic film, or a piece from a moulded part) |

|---|---|

| Temperature range | Ambient to 350°C |

| Heating rate | 10 -100°C/min |

| Automatic output |

Glass Transition Tg (°C) |

|

Melting Point Tm (°C) |

|

|

End Point (°C) |

|

| Identification: | Polymer Type |

| Confirmation: | QIS value of similarity |

| Comparison: | QIS value of similarity |

| Additional output |

Complex thermo-mechanical property data: |

| - Tan delta | |

| - Stiffness (N/m) | |

| - Delta T (ΔT, °C) | |

| - Moulding displacement (mm) | |

| Printed outputs | Batch summary report |

| QIS test results report | |

| Sample identification | |

| Certificate of confirmation | |

| Optional accessories | Melt Flow Indication (MFi) |

| Sample viewing camera system |

The identiPol in action at one of Europe’s largest pipe manufacturers: Polypipe Civils

The identiPol is a quality assurance tool that identifies and assesses the quality of thermoplastics. The system has been specifically designed to provide a quick assessment of incoming material and its suitability for use in production. It can also be used to check manufactured parts.

Suitability assessment is achieved by an automated comparison of new batches of material that are compared against known good batches (stored as reference sets) that have been previously tested. This identification, confirmation and comparison of material, together with the MFi value identification (additional software option) allows the identiPol QA2 to offer a complete analysis of incoming and outgoing material.

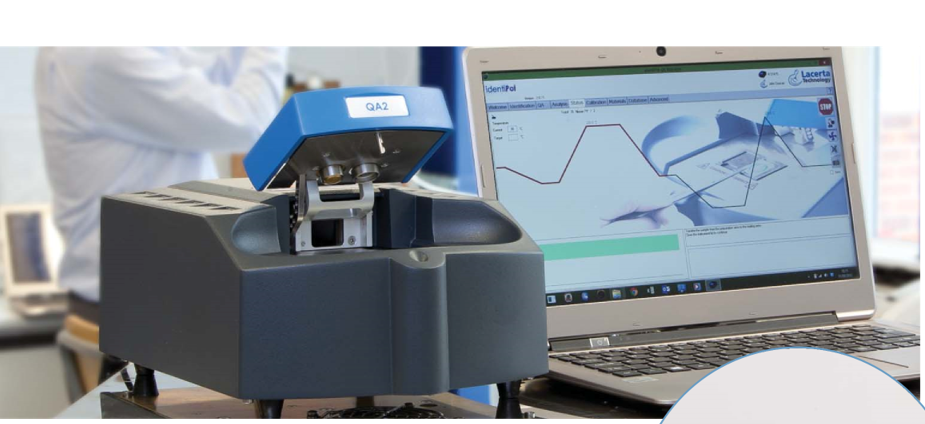

The QA2 offers an intelligent system that self-optimises test conditions, leaving an operator with only having to enter supplier, material and batch information into the software, before performing a test. Built in diagnostics ensures that samples are always run under optimum conditions and requires no monitoring while the test runs. With this simplicity and automation, running a test and obtaining test results can be performed by inexperienced operators and the total test time is just 15 minutes. This includes sample preparation as well as moulding.

Anything from granulate, flake, powder or pieces cut from finished mouldings can be analysed.

-

2026년 2월 현재, 서비스 가능합니다.플라스틱 품질 및 정성 분석기 - Plastic Identification, Confirmation, and Comparison관리자 2025-10-29 05:31:36