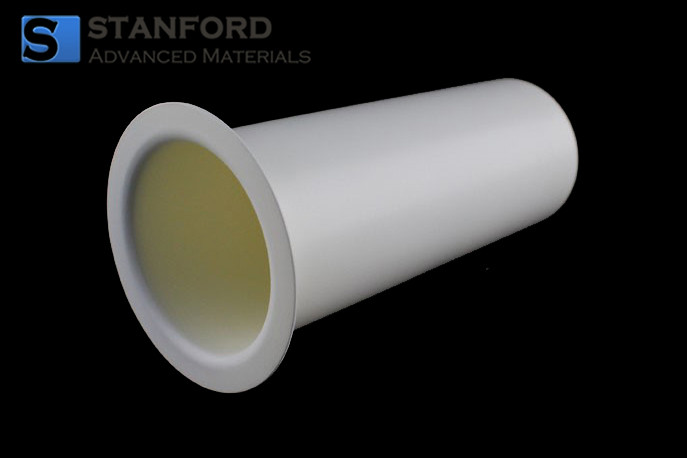

Pyrolytic Boron Nitride OLED Crucible is a kind of PBN Crucible used in OLED and CIGS evaporation technology. Stanford Advanced Materials (SAM) specializes in delivering Pyrolytic Boron Nitride OLED Crucible with high purity and competitive prices.

Pyrolytic Boron Nitride OLED Crucible Description

Pyrolytic Boron Nitride OLED Crucible is a kind of PBN Crucible used in OLED and CIGS evaporation technology. It is widely used in metal and semiconductor evaporation for its ultra-high purity, chemical inertness, excellent high-temperature resistance, and high-temperature stability.

Pyrolytic Boron Nitride OLED Crucible Specifications

|

Material |

PBN |

|

Purity |

≥99.99% |

|

Density |

1.95-2.22 g/cm3 |

|

Tensile Strength |

153.86 N/mm2, 112 MPa |

|

Bending Strength |

243.63 N/mm2, 173 MPa |

|

Compression Strength |

154 MPa |

|

Max. Working Temperature |

2400℃ |

|

Specific Heat Capacity |

0.89 J/g·℃ |

|

Electrical Resistivity |

2*1015 Ω·cm |

|

Dielectric Strength (RT) |

>2*105 D.C. Volts/mm |

|

Thermal Conductivity (W/m·K) |

43-60 |

*The above product information is based on theoretical data. For specific requirements and detailed inquiries, please contact us.

Pyrolytic Boron Nitride OLED Crucible Applications

1. OLED Manufacturing: Essential for the evaporation and deposition of organic materials onto substrates during OLED production, due to their high thermal stability and non-reactivity with organic compounds.

2. High-Purity Processing: Provides a clean, contamination-free environment necessary for the deposition of high-purity organic materials, ensuring the performance and longevity of OLED devices.

3. Thermal Management: Withstands the high temperatures required for the deposition processes, ensuring stable and consistent manufacturing conditions.

4. Advanced Materials Processing: Utilized in the research and development of new OLED materials and processes, benefiting from their durability and ability to handle high-temperature operations.

Pyrolytic Boron Nitride OLED Crucible Packaging

Our products are packaged in customized cartons of various sizes based on the material dimensions. Small items are securely packed in PP boxes, while larger items are placed in custom wooden crates. We ensure strict adherence to packaging customization and the use of appropriate cushioning materials to provide optimal protection during transportation.