Moorfield의 nanoPVD 제품군 중 최신 모델인 T15A 모델은 유기물 및 금속 증착을 위한 저온 증발(LTE) 및 standard resistive evaporation source를 각각 장착할 수 있습니다. 우수하고 효율적인 성능으로 OLED, OPV 및 OFET의 고성능 금속, 벤치탑 패키지의 유기 증착 연구에 이상적입니다.

Techniques:

Thermal evaporation

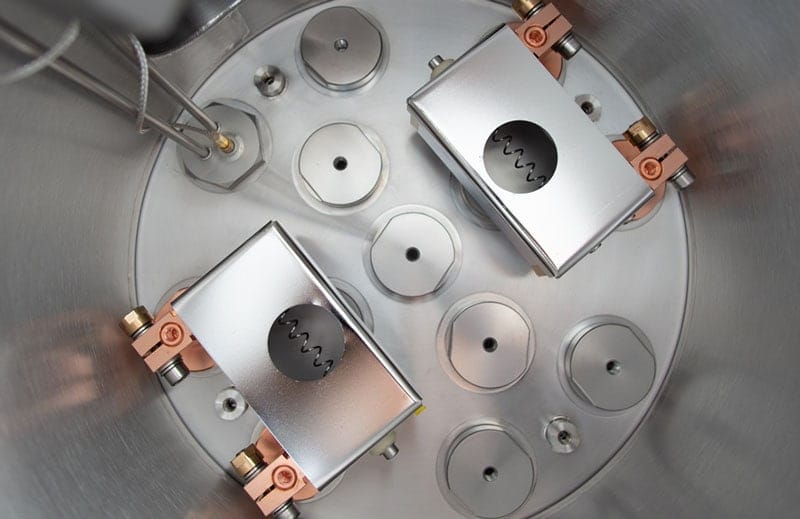

LTE sources are low thermal-mass for better control when evaporating volatile organic materials, while metals sources are our box-shielded TE1 models for efficient deposition and reduced cross-contamination.

Chamber access is via a hinged lid, that opens to reveal a stage suitable for holding substrates up to 4″ diameter. The chamber is tall, allowing for high-uniformity coating via evaporative techniques.

The units are easy to control via a touchscreen HMI interface, simple to maintain, have low running costs and come with a comprehensive range of safety features.

With a turbomolecular pumping system, high-vacuum base pressures, straightforward automated control via a touchscreen HMI and a range of options for flexible configuration, the nanoPVD-T15A is a versatile, efficient solution for world-class R&D applications.

Key features

- Benchtop configuration

- Organics and metals evaporation sources

- High aspect-ratio chamber for uniform coating

- Fully automatic operation via touchscreen HMI

- Define/save multiple process recipes

- Up to 4” diameter substrates

- Base pressures <5 × 10-7 mbar

- Equipped for easy servicing

- Comprehensive safety features

- Proven performance

Options

- Dry backing pump

- Fast chamber vent

- Automatic high-resolution pressure control

- Up to 4 LTE sources for organics

- Up to 2 evaporation sources for metals

- 500 °C substrate heating stage

- Substrate rotation, Z-shift and shutters

- Quartz crystal sensor head

Typical configurations

Metals deposition

Two thermal evaporation sources for metals evaporation with shutters and quartz crystal sensor head for rate/thickness calibration.

Organics deposition

Four LTE sources for organics deposition with shutters and quartz crystal sensor head for rate/thickness calibration.

Metals and organics deposition

Two thermal evaporation sources and two LTE sources for metals and organics PVD, with shutters and quartz crystal sensor head.

Service requirements

All nanoPVD-T15A systems require chilled water, dry compressed air, nitrogen for venting (optional) and electrical power. Exact requirements will be provided with quotations or on request.

The latest model in Moorfield’s nanoPVD range, model T15A can be equipped with low-temperature evaporation (LTE) and standard resistive evaporation sources for deposition of organics and metals, respectively. High-performance metals, organic evaporation in compact packages for benchtop location. Superior, efficient performance and ideal for OLED, OPV and OFET research.