nanoPVD-S10A-WA는 nanoPVD-S10A의 기능을 확장한 벤치탑 패키지에서 최대 8" 직경의 기판을 균일하게 코팅할 수 있도록 하는 Wide-Area configuration입니다. RF 및 DC 마그네트론 스퍼터링으로 금속 및 절연 재료를 증착하는 데 사용됩니다.

Techniques:

Physical vapour deposition

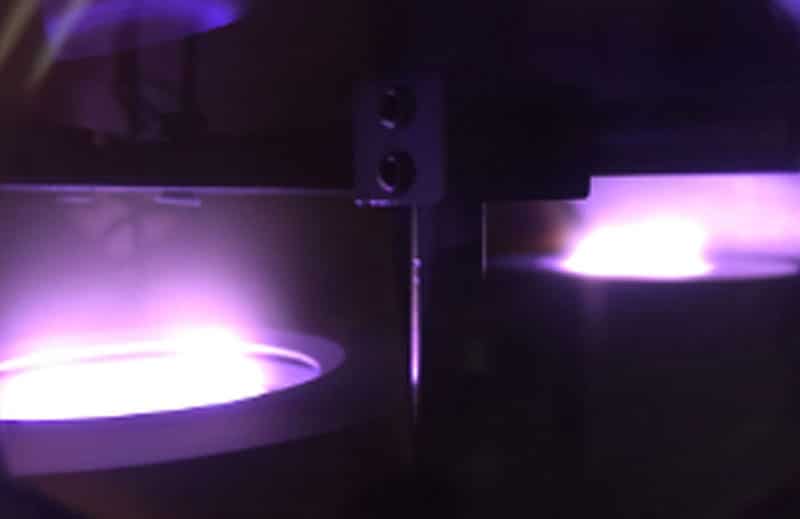

While keeping the same chamber design, the Wide-Area version of the nanoPVD-S10A contains magnetron sputtering sources oriented directly upwards towards substrate platens. This arrangement in combination with substrate rotation and exposure plates with specially-designed orifices allows for coating of substrates up to 8″ diameter for applications in which tight uniformity specifications are not critical.

Like the nanoPVD-S10A, magnetrons are water-cooled for sustained high-power operation and accept industry-standard targets. In addition, nanoPVD-S10A-WA units come with all attractive features of the nanoPVD range including turbomolecular pumping systems, recipe-based automated operation via touchscreen HMIs, and compact designs for benchtop location.

Key features

- Application-specific configuration for the nanoPVD-S10A

- Uniform coating for substrates up to 8” diameter

- Water-cooled magnetron sputtering sources for industry-standard 2″ targets

- MFC-controlled process gases

- DC and/or RF power supplies

- Fully automatic operation via touchscreen HMI

- Define/save multiple process recipes

- Base pressures <5 × 10-7 mbar

- Equipped for easy servicing

- Comprehensive safety features

- Cleanroom compatible

- Proven performance

Options

- Dry backing pump

- Fast chamber vent

- Automatic high-resolution pressure control

- Additional process gases

- Up to 2 magnetron sputtering sources

- RF and/or DC power supplies

- SputterSwitch power supply/source switching technology

- Quartz crystal sensor head

Typical configurations

As per your requirements

The nanoPVD-S10-WA is a semi-custom tool, with final design being subject to customer requirements.

Service requirements

All nanoPVD-S10A systems require chilled water, dry compressed air, nitrogen for venting (optional), process gas supplies, and electrical power. Exact requirements will be provided with quotations or on request.

The nanoPVD-S10A-WA is a Wide-Area configuration that extends the capabilities of the nanoPVD-S10A to allow for even coating of substrate diameters up to 8″, in a benchtop package. RF and DC magnetron sputtering allow for deposition of both metals and insulating materials.