CS Cooling Shrouds

- Compatible with most MBE systems

- Highest welding and steel quality

- Different kinds of cooling shrouds

- Water or liquid nitrogen cooling

- Optional: integrated shutter

Introduction

The separate cooling shrouds can be used in combination with evaporation sources that have no integrated water cooling. Due to their all-stainless steel construction, they are bakeable up to 250°C (TC reading 400°C) without water flow.

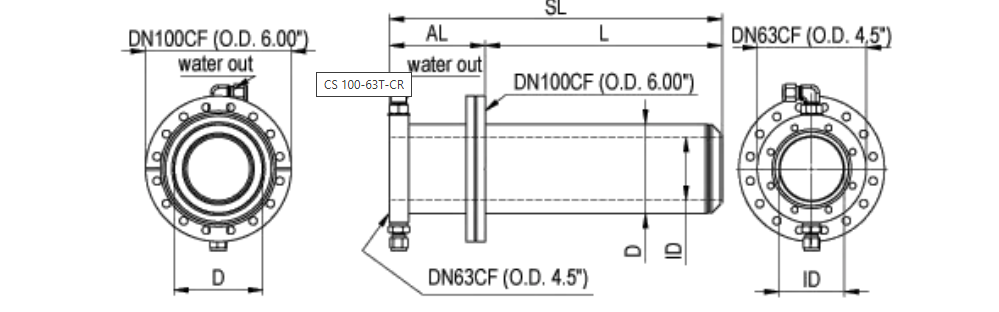

Furthermore, the option “closed cooling” (option -C) is available for CS type cooling shrouds. In this case the cooling tube is welded directly onto the flange.

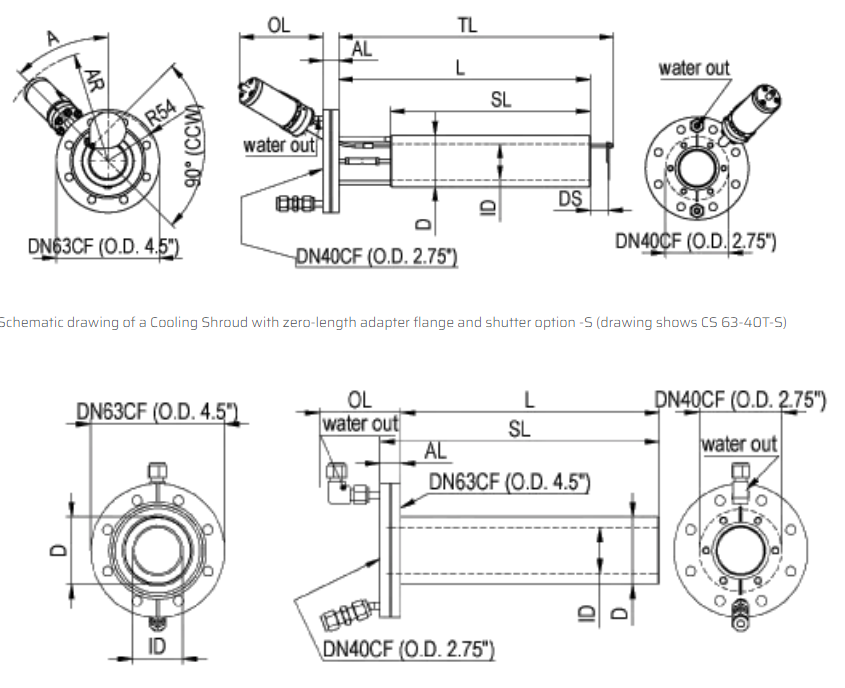

Cooling shrouds fit most port flanges DN63CF or larger. They are equipped with a mounting flange to the port and a source flange which corresponds with the mounting flange of the evaporation source. Instead of an additional flange (option -R) a zero-length adapter flange can be used as mounting flange as well as source flange.

The CS 200-150T is an example of a vertically mounted (face-down) cooling shroud, typically used for substrate manipulators, wafer heaters or measurement equipment in MBE systems.

Our cooling shrouds are compatible with most MBE systems as for example Riber, VG Semicon, Varian, Eiko, DCA, Veeco, Applied Epi and Omicron. For other systems please specify mounting flange, in-vacuum length, in-vacuum diameter, substrate size and the distance from cell orifice to the substrate. Cooling shrouds with mounting flange sizes from DN63CF up to DN200CF are available see Specific data table below.

Cooling and Shutter Options

We offer water cooling shrouds. Liquid nitrogen (LN) cooling is possible for some shrouds on request. Optionally we offer shrouds with the cooling tube welded directly onto the flange (“closed cooling” option -C).

Some cooling shrouds are available with additional shutter (option -S). The shutter rod is guided in a tube inside the cooling shroud and a DN16CF flange is added to the mounting flange to carry the rotary shutter feedthrough. For automated processes we offer electrically driven soft-acting rotary shutter modules RSM in combination with shutter control units SCU .

For general information on CF mounting flanges see Flange, Gasket and Tube Dimensions .

Specific data

For general information on CF mounting flanges see Flange and Gasketdimensions .

The flanges in the table below are all type DNxxCF if not further marked.

Used letter-code:

K / F: ISO-K / ISO-F flange

T: Flange with tapped holes

S: Option shutter

C: Option closed cooling shroud

R: Option retracted source flange

LN: Option liquid nitrogen cooling medium

G: Threads for water connection, diameter = x/x"

Dx: Welded-in cooling water pipes, fitting size = x mm

|

Product |

Mounting flange |

Source flange |

Options |

In-vacuum length L |

In-vacuum outer |

In-vacuum inner |

Adapter length AL |

Shroud length SL |

Cooling water |

|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

|

|

CS |

40(T) |

63(T), 100 |

C, R |

220...400 |

44...115 |

29...72 |

17...90 |

max. L+AL |

G1/8" |

|

CS |

63 |

40(T) |

S, C, R |

220...400 |

54...75 |

35...41 |

17...90 |

max. L+AL |

D6 |

|

CS |

63 |

63 |

C, R |

220...267 |

62...70 |

50...57 |

17...80 |

max. L+AL |

G1/8" |

|

CS |

63 |

100 |

C, R |

220...300 |

57...70 |

38...57 |

34...90 |

max. L+AL |

G1/8" |

|

CS |

75 |

40, 50(T), 63, 100 |

C, R |

121...287 |

57...80 |

39...66 |

17...162 |

max. L+AL |

D6, G1/8" |

|

CS |

100 |

40(T) |

S, C, R, LN |

220...400 |

57...92 |

39...48 |

20...110 |

max. L+AL |

D6, G1/8" |

|

CS |

100 |

63(T) |

S, C, R |

220...400 |

76...93 |

57...66 |

20...110 |

max. L+AL |

D6, D8, G1/4", G1/8" |

|

CS |

100 |

100 |

S, C, R |

245...400 |

57...99 |

41...84 |

20...110 |

max. L+AL |

G1/8" |

|

CS |

125 |

63(T), 100, 150 |

C, R |

245...400 |

89...115 |

60...89 |

21...110 |

max. L+AL |

G1/4", G1/8" |

|

CS |

150 |

63(T), 100, 125 |

S, C, R, LN |

245...400 |

89...146 |

66...140 |

21...150 |

max. L+AL |

D6, D8, G1/4", G1/8" |

|

CS |

160 |

63(T), 160F |

C, R |

245...589 |

93...140 |

66...104 |

21...150 |

max. L+AL |

G1/4", G1/8" |

|

CS |

200, 250 |

100, 150(T), 200 |

C, R |

245...500 |

169...250 |

133...200 |

24...180 |

max. L+AL |

D8, G1/4", G1/8" |

The table shows a selection of CS types with possible options and size ranges. Further size and option combinations are possible on request. Please contact us

Product code:

e.g. CS 100-63-CR-S-LxxxD95

is a closed water cooling shroud with DN100CF mounting flange and retracted DN63CF source flange, integrated shutter and in-vacuum diameter 95 mm.