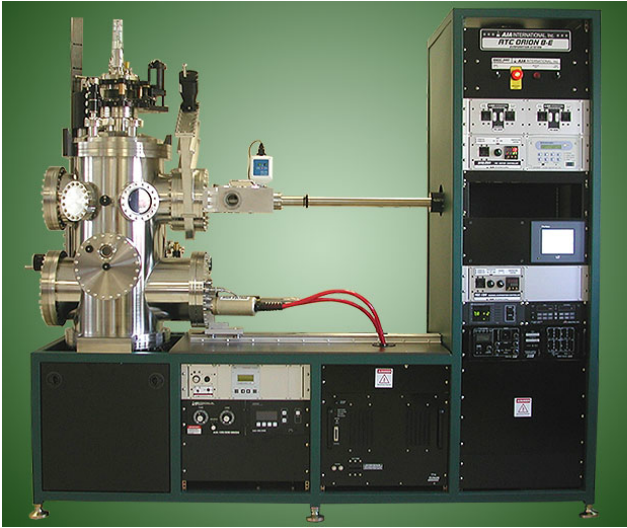

ATC-E Series Electron Beam Evaporation System은 ATC-E 및 ATC Orion-8E 원통형, UHV 스타일 챔버, ATC 2030 및 ATC 2036 HV 스타일 박스 코터 버전으로 제공됩니다. AJA International의 이러한 physical vapor deposition 시스템은 최적의 성능을 제공하고 최고 품질의 구성 요소를 활용하면서 탁월한 가치를 제시합니다. 본 제품군은 고도로 진화된 ATC & ATC Orion 스퍼터링 장비로부터 수 많은 디자인 특징과 공통적인 부품을 계승받아, 싱글 또는 멀티-포켓 선형 및 회전형 전자빔 소스, 열 증발 소스, 이온 / 플라즈마 소스, Knudsen 셀, 유기물 용 저온 증발 셀, Radak 소스 및 마그네트론 스퍼터 소스를 장착 할 수 있습니다. 또한 이러한 시스템은 로드 락 (load lock), QCM 모니터링 및 제어, 가열 또는 냉각 기판 홀더, planetaries, 다양한 펌핑 패키지 및 자동 제어와 함께 사용할 수 있습니다.

TYPICAL E-BEAM EVAPORATION SYSTEM CONFIGURATIONS

ATC-ORION-8E UHV

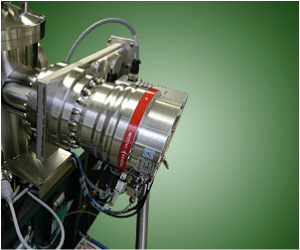

ATC-Orion-8E UHV 모델은 loading과 service를 위한 편리한 슬라이드 메커니즘에 5 Pocket Linear E Beam Source를 장착한 컴팩트하고 경제적 인 UHV 코터. 또한 터보 펌프 식 진공 로드 락 (load-lock) 기능을 가진 시스템입니다.

Compact, economical UHV coater with 5 Pocket Linear E Beam Source on convenient slide mechanism for loading and service. System also features turbo-pumped vacuum load-lock.

ATC 2200-E

ATC 2200-E 모델은 직경 22 ", 높이 36"의 UHV e-beam evaporator 입니다. 6개의 포켓, inear UHV e-beam source, 2개의 Radak thermal evaporator, 터보 펌프 식 로드 락 (turbo-pumped load-lock)이 포함됩니다.

22" diameter, 36" high UHV e-beam evaporator with (6) pocket, linear UHV e-beam source, (2) Radak thermal evaporators and turbo-pumped load-lock.

ATC-2030-E HV

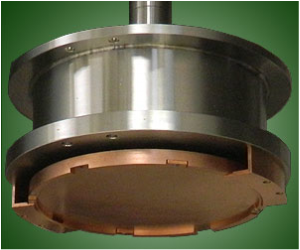

ATC-2030-E HV 모델은 로드 락 (load-lock)과 수냉식 기판 홀더, 전면 복사 기판 가열 (radiant substrate heating) 기능을 가진 6 pocket rotary e-beam source를 포함하고 있습니다.

6 pocket rotary e-beam source with load-lock, water-cooled substrate holder, and front side radiant substrate heating.

ATC-2036-E HV

ATC-2036-E HV 모델은 1,000°C 기판 가열 기능이 있는 6 포켓 회전 전자빔 소스 (rotary e-beam source )및 웨지 필름을 위해 프로그래밍이 가능한 선형 기판 셔터가 포함됩니다.

6 pocket rotary e-beam source with 1000°C substrate heating, and programmable linear substrate shutter for wedge films.

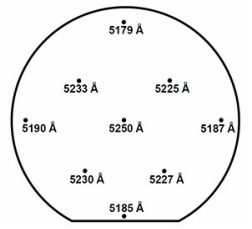

TYPICAL RATE / UNIFORMITY DATA

with simple, azimuthal rotation, run for 75 seconds at 8450V, 24 mA,

500 mm working distance. Uniformity is ±0.7%.

ATC-E Series Evaporation System은 선택된 chamber, source, 기판 캐리어 및 일반적 구성에 따라 고속과 저속, multi-layer 및 co-deposition의 애플리케이션에 맞게 구성 할 수 있습니다. 요구되는 속도, 안정성 및 필름 특성을 확보하도록 증발시킬 각각의 재료에 대해 적절한 파워, 도가니 라이너 또는 보트 재료, soak 및 XY 스윕을 결정해야 합니다. 일반적으로 열 전달 특성이 좋은 재료 (예, Al)는 XY 스윕이 필요하지 않지만 라이너 (Au)가 필요할 수 있는 반면, 열적 특성이 좋지 않은 재료 (예, Cr)는 e- beam 파워가 XY 스윕으로. 확산되지 않는 한 터널링 및 스피팅하는 경향이 있습니다. 최상의 균일성(uniformity)을 확보하는 데는 적절한 기판 픽스쳐가 필요합니다.

간단한 azimuthal rotation으로 100mm 직경의 Si 웨이퍼에 XY 스윕을 사용하여 SiO2를 증착하고 8450V, 24mA, 500 mm의 working distance에서 75 초 동안 실행되었습니다.

균일성은 ±0.7 %입니다.

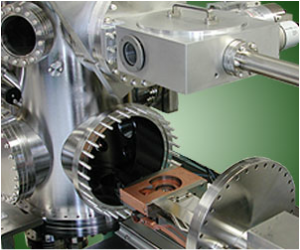

EVAPORATION SOURCES

AJA offers a variety of evaporation sources on the ATC-E, ATC Orion-E and ATC 2030/36-E deposition systems. The vertical cylinder ATC-E and ATC Orion-E UHV chambers are best suited for linear, multi-pocket, UHV, e-beam sources which are side mounted and attached to a convenient slide rail for service and loading access. Spare ports on the chamber bottom straddling the linear e-beam source allow for the addition of up to 4 thermal evaporation sources. Smaller ATC Orion-TE chambers are ideally suited to multiple, small, thermal evaporation sources (k-cell, resistive boat, Radak, low temp organic) often in combination with magnetron sputter sources. The ATC 2030/36-E HV box coaters with large loading doors are generally fitted with rotary pocket e-beam sources, resistive thermal sources and substrate carriers of all forms - heated, cooled, tilting, planetary, wedge shuttered, etc.

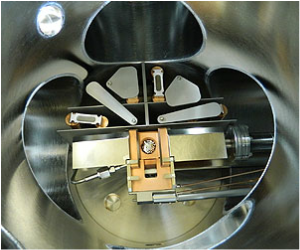

Source on easy access slide rail system.

stepper controlled automated indexing.

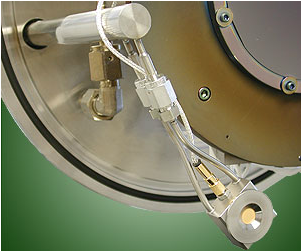

with RF LEIS plasma/ion source.

(4) thermal evaporation sources.

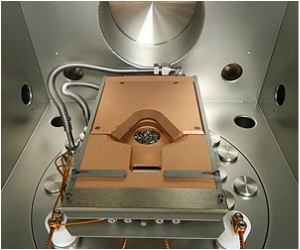

SUBSTRATE HOLDERS - HEATING / COOLING

AJA can fit your customized evaporation system with a wide variety of substrate holders including motorized, rotating substrate holders and planetaries to achieve excellent uniformity, heating up to 1000°C, substrate RF and DC bias capability, in-situ manual or motorized Z motion (for working distance adjustment and load-lock transfer) and in-situ mask exchange (available only with certain configurations). Cooled substrate carriers ( H2O/ LN2) are also available depending on the application requirements. Process gas ring or gas distributor options are offered for reactive processing or applications requiring an anneal step.

with rotation and Z-motion

water-cooled wedge type shutter for high temperature

gradient films, and secondary “swing in” LN2 cooled

substrate holder

front side radiant heating

capable of accommodating (4) 4” wafers

with 800°C heating, rotation, and +/- 180° tilting

with water cooling, rotation, and +/- 180° tilting

PHASE II-E COMPUTER CONTROL

The AJA Labview based Phase II-E computer control system is offered on all ATC-E Series Evaporation Systems. This straightforward, user friendly control system utilizes a large, flat-screen laptop in a 19” rack drawer connected to a single 7” high x 19” wide rack mount hardware module. The back panel of the hardware module is populated with connectors to interface to all aspects of the sputtering system.

The Phase II-E control system allows the user to operate in either the “manual mode” or the “automated processing mode.” In the “automated processing mode”. the user designs process “layers” which are then compiled and saved as a “process”. The system allows 10 unique user entry points which are accessible only by password, limiting access to a user’s layers and preventing unexpected corruption of a user’s saved processes.

The standard Phase II-E control system will accommodate up to (2) e-beam sources, (4) thermal sources, (1) ion source or (1) RF bias supply, (3) process gases, (2) thickness monitors, (6) shutters, closed loop automatic pressure control if required and substrate temperature control and motion. Processes are aborted if proper feedback is not detected. Special “soak layers” can be easily incorporated into the process. Finally, data logging is standard with an adjustable refresh period. Process data can be downloaded to common spreadsheet programs. The Phase II E is often linked directly to a deposition controller with multiple QCM heads.

Large screen laptop on convenient slide drawer

for Labview based ATC system computer control.

Replacement laptops are always in stock at AJA.

Phase II E PLC in compact 4U rack mount case.

This module is fitted from the outset with all receptacles

for quick field retrofits/upgrades.

INFICON SQC310

For many e-beam system application, AJA uses the INFICON SQC310 Series deposition controller. The SQC310 is fully interfaced to control electron beam source indexing, shutter control, and both single and co-evaporation (SQC-310-C) processes. A large on board storage capacity of 100 individual processes and 1,000 layers, enables easy access to recall processes and parameters for sample repeatability. The controller package also includes a Windows program for developing, testing, and downloading processes, and for logging instrument data to a customer’s PC if desired for process analysis and quality control.

SYSTEM OPTIONS

slide drawer

380V systems

Pump Control

Ø mm substrates